Dealing with a Small Crack in Your Windshield: What You Need to Know

By:Admin

Company News & Blog

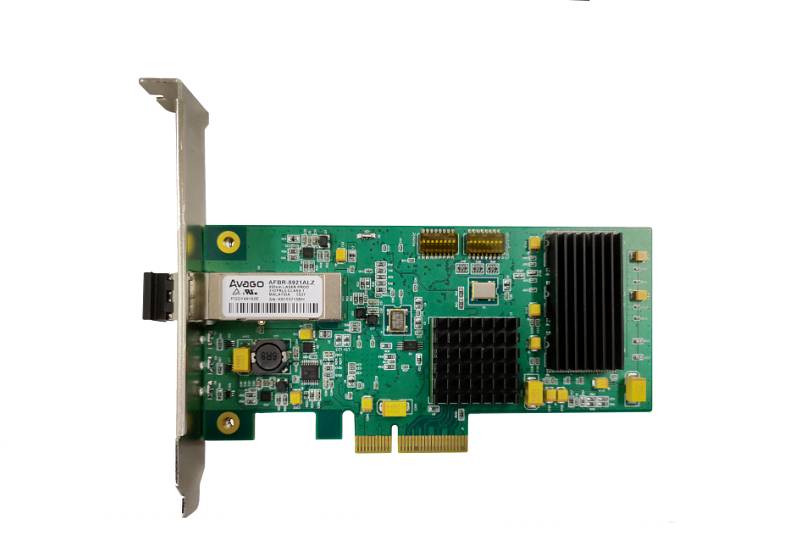

Optimizing Your Printed Circuit Board Layout for Efficiency and Performance

Printed Circuit Board Layout (PCB) is a crucial aspect of electronic manufacturing that determines the performance and reliability of electronic devices. Proper PCB layout design is essential for the effective functioning of electronic products, making it an integral part of the manufacturing process.{} is a leading electronic manufacturing company that specializes in providing high-quality PCB layout services. With years of experience and expertise in the field, the company has established itself as a reliable and trusted partner for businesses seeking exceptional PCB layout solutions.The PCB layout process is complex and requires careful attention to detail. It involves the design and arrangement of various components on the printed circuit board to ensure optimal performance and functionality. A well-designed PCB layout not only enhances the overall performance of the electronic device but also contributes to its longevity and durability.{} understands the importance of PCB layout in electronic manufacturing and has invested heavily in state-of-the-art technology and skilled professionals to offer top-notch PCB layout services. The company utilizes advanced software and tools to create precise and efficient PCB layouts that meet the specific requirements of its clients.In addition to offering standard PCB layout services, {} also provides custom PCB layout solutions tailored to the unique needs of individual projects. This customized approach allows the company to deliver highly specialized and optimized PCB layouts that align with the specific requirements and standards of its clients.Moreover, {} is committed to maintaining the highest quality standards in its PCB layout services. The company follows rigorous quality control measures and thorough testing processes to ensure that the PCB layouts meet the industry's strict standards for performance and reliability.Furthermore, {} has a team of highly skilled and experienced PCB designers who possess in-depth knowledge of industry best practices and design principles. This expertise allows the company to consistently deliver exceptional PCB layout solutions that exceed customer expectations.The company's dedication to excellence and customer satisfaction has made it a preferred choice for businesses across various industries, including automotive, telecommunications, consumer electronics, and more.{}'s PCB layout services have played a crucial role in helping companies develop innovative and reliable electronic products that meet the ever-evolving demands of the market.As a customer-centric company, {} understands the importance of meeting project deadlines and budget constraints. The company's efficient and streamlined PCB layout process ensures timely delivery without compromising on quality, making it a reliable partner for businesses with strict project timelines and budgetary requirements.In conclusion, {} is a leading provider of high-quality PCB layout services that are essential for the success of electronic manufacturing projects. With its commitment to excellence, advanced technology, and skilled professionals, the company continues to set the standard for exceptional PCB layout solutions in the industry. Businesses looking for reliable and efficient PCB layout services can trust {} to deliver customized and high-performance solutions to meet their specific needs.

Optimal BGA Reflow Temperature for Efficient Soldering Process

BGA Reflow Temperature Plays Crucial Role in Ensuring Product QualityIn the rapidly evolving electronics industry, the demand for high-quality, reliable products is at an all-time high. As electronic devices become more complex and miniaturized, the need for precise manufacturing processes becomes increasingly important. One critical aspect of electronics manufacturing is the BGA reflow temperature, which plays a crucial role in ensuring the integrity and reliability of electronic products.{Company} is a leading provider of advanced manufacturing solutions for the electronics industry. With a strong focus on innovation and quality, {Company} has established itself as a trusted partner for companies looking to enhance their manufacturing processes and achieve superior product quality.BGA (Ball Grid Array) reflow soldering is a key process in electronics manufacturing, especially for complex, high-density PCBs (Printed Circuit Boards). During the BGA reflow process, the solder paste is heated to a specific temperature, causing it to melt and form a strong bond between the BGA component and the PCB. This process requires precise control of temperature, time, and atmospheric conditions to ensure the formation of reliable solder joints.The reflow temperature is a critical parameter in the BGA reflow process. It must be carefully controlled to avoid issues such as insufficient solder melting, solder ball deformation, or damage to the components due to excessive heat. The BGA reflow temperature profile typically consists of several stages, including preheating, soaking, reflow, and cooling, each requiring precise temperature control to achieve the desired solder joint quality.{Company}'s advanced reflow soldering systems are designed to meet the stringent requirements of modern electronics manufacturing. With advanced temperature control capabilities and real-time process monitoring, {Company} ensures that the BGA reflow process is carried out with the highest level of accuracy and repeatability. This results in superior solder joint quality, reduced defects, and ultimately, higher product reliability.In addition to temperature control, {Company}'s reflow soldering systems also offer advanced features such as nitrogen atmosphere control, automatic profile generation, and comprehensive data logging. These features enable electronics manufacturers to optimize the BGA reflow process for their specific requirements, ensuring consistent and reliable results across different product lines and production batches.With a strong focus on research and development, {Company} continually strives to innovate and improve its reflow soldering solutions. The company's team of experienced engineers works closely with customers to understand their unique challenges and requirements, and develop tailored solutions that address their specific needs. This customer-centric approach has earned {Company} a reputation as a reliable partner for electronics manufacturers seeking to enhance their manufacturing capabilities.As the electronics industry continues to evolve, the importance of precise manufacturing processes, such as BGA reflow soldering, cannot be overstated. With its advanced reflow soldering systems and unwavering commitment to quality, {Company} is well-positioned to serve the needs of manufacturers looking to achieve superior product quality and reliability in an increasingly competitive market.In conclusion, the BGA reflow temperature is a crucial factor in ensuring the integrity and reliability of electronic products. With its advanced reflow soldering systems and customer-focused approach, {Company} is at the forefront of providing innovative solutions for the electronics manufacturing industry. By partnering with {Company}, electronics manufacturers can benefit from superior temperature control, advanced features, and expert support, ultimately leading to higher product quality and customer satisfaction.

Innovative Double Sided Circuit Board Technology: What You Need to Know

[Company Name] Unveils Innovative Double Sided Circuit Board[City, State] - [Date] - As technology continues to advance at a rapid pace, the demand for more efficient electronic components has become increasingly significant. In response to this need, [Company Name], a leading manufacturer in the electronics industry, has unveiled its latest innovation - a double sided circuit board.This cutting-edge technology represents a major breakthrough in the field of electronic engineering. The double sided circuit board offers a number of advantages over traditional single sided boards, including increased functionality, improved signal integrity, and greater design flexibility. With the ability to accommodate more complex circuitry in a smaller space, this innovation is set to revolutionize the way electronic devices are manufactured.The double sided circuit board is designed to meet the evolving needs of the industry, as electronics continue to become smaller, more powerful, and more integrated into everyday life. By offering a solution that combines superior performance with enhanced manufacturing efficiency, [Company Name] is poised to make a significant impact on the electronic components market.The development of this technology is a result of [Company Name]'s commitment to research and development. With a team of highly skilled engineers and researchers, the company has invested significant resources into exploring new materials, processes, and designs to push the boundaries of what is possible in the world of electronics. The unveiling of the double sided circuit board is a testament to their dedication to innovation and their ability to deliver solutions that meet the needs of the industry.In addition to its technical capabilities, the double sided circuit board is also environmentally friendly. By reducing the amount of material and resources required for manufacturing, [Company Name] is helping to minimize the impact of electronic waste on the environment. This commitment to sustainability reflects the company's ethos of responsible and ethical business practices.The unveiling of the double sided circuit board has generated significant interest within the electronics industry. With its potential to revolutionize the way electronic devices are designed and manufactured, industry experts and professionals are eager to see how this technology will shape the future of electronics.In a statement, [Company Name] expressed their enthusiasm for the potential impact of the double sided circuit board: "We are incredibly excited to introduce this groundbreaking technology to the market. The development of the double sided circuit board represents a major milestone for our company and a significant advancement for the electronics industry as a whole. We believe that this innovation will open up new possibilities for the design and manufacturing of electronic devices, and we are committed to working with our partners and customers to realize the full potential of this technology."As the world of electronics continues to evolve, [Company Name] remains at the forefront of innovation. With the unveiling of the double sided circuit board, the company has once again demonstrated its ability to push the boundaries of what is possible in the world of electronic components. This latest development is a testament to their dedication to excellence and their commitment to delivering solutions that meet the evolving needs of the industry.

Cutting-Edge Single PCB Technology Revolutionizes Electronic Manufacturing Process

In the world of electronics, printed circuit boards (PCBs) have become the go-to solution for creating complex and intricate circuits. However, the traditional process of designing and manufacturing PCBs involves multiple steps, which can take up a significant amount of time and resources. However, that is all changing with the emergence of Single PCB, a revolutionary technology that promises to reduce the complexity and cost of PCB design and manufacturing.Single PCB is a brand new technology that allows for the creation of PCBs in a single step. This means that designers can create entire circuits using just a single board, which saves time and resources. Additionally, this technology eliminates the need for multiple components, reducing the overall cost of PCB production.At the forefront of this technology is a company, whose innovative single PCB technology has the potential to revolutionize the electronics industry. With over a decade of experience in PCB design and manufacturing, this company has developed a comprehensive range of solutions that has set it apart from its competitors.Headquartered in [city, country], the company prides itself on being a leading provider of PCB related services and solutions. With a team of highly skilled and experienced professionals, the company has built a reputation for excellence in the industry.The company's single PCB technology is the result of years of research and development. The technology has been specifically designed to simplify the process of PCB design and production, making it more accessible to a wider range of users.One of the biggest advantages of the single PCB technology is its ability to reduce the complexity of the design process. With traditional PCB manufacturing, designers had to create multiple boards and then connect them using a variety of connectors and wires. This process was time-consuming, and there was always the risk of errors occurring during assembly. However, with the single PCB technology, designers can create an entire circuit on a single board, eliminating the need for additional components and saving time and money.Another important benefit of the single PCB technology is the reduction in the overall cost of PCB production. With traditional PCB manufacturing, there were multiple steps involved, including designing the boards, assembling the components, and testing the finished product. However, with single PCB technology, the entire process can be completed in a single step, reducing the overall cost of production.The single PCB technology has also been designed with flexibility in mind. This means that designers can create circuits of varying complexity, adapting the technology to suit their specific needs. Additionally, the technology can be used to create a wide range of products, from simple electronic toys to complex medical equipment.As the world becomes more reliant on technology, the demand for innovative and efficient PCB manufacturing solutions is only going to increase. Single PCB technology is poised to meet this demand head-on, offering a simple and cost-effective solution for creating cutting-edge electronic products.In conclusion, the emergence of Single PCB technology is a game-changer for the electronics industry. With its simplified design process, reduced manufacturing costs, and flexibility, this technology has the potential to reshape the way we design and manufacture electronic products. The company behind this technology is poised to lead the way in the single PCB market, offering customers a comprehensive range of solutions that are designed to meet their specific needs and requirements.

Top Contract Manufacturing Services for Your Business Needs

In today's rapidly evolving manufacturing industry, the importance of a reliable and efficient contract manufacturer cannot be overstated. For businesses looking to outsource their production needs, finding the right partner is crucial for maintaining high-quality standards and meeting demand. This is where the expertise of {Company Name}, a leading contract manufacturer, comes into play.{Company Name} has been a key player in the contract manufacturing industry for {number} years. It has established a strong reputation for its ability to deliver a wide range of manufacturing solutions, from product design and prototyping to full-scale production and logistics. The company prides itself on its commitment to quality, efficiency, and customer satisfaction, making it a top choice for businesses in need of contract manufacturing services.With state-of-the-art facilities and a dedicated team of experts, {Company Name} has the capacity to handle complex manufacturing projects across various industries, including {list of industries}. Its in-house capabilities include CNC machining, injection molding, precision metal stamping, and assembly, among others. This extensive range of capabilities allows {Company Name} to offer comprehensive manufacturing solutions, from start to finish, all under one roof.In addition to its manufacturing capabilities, {Company Name} places a strong emphasis on continuous improvement and innovation. It invests in the latest technology and equipment to ensure that its processes are at the forefront of industry standards. This commitment to staying ahead of the curve enables {Company Name} to adapt to the evolving needs of its clients and the marketplace, providing them with a competitive edge in their respective industries.One of {Company Name}'s key strengths is its flexible and collaborative approach to working with clients. It recognizes that every business has unique requirements and works closely with each client to understand their specific needs. Whether it's a small batch production run or a large-scale manufacturing project, {Company Name} is dedicated to providing personalized solutions that align with its clients' goals and objectives.Another factor that sets {Company Name} apart from its competitors is its unwavering commitment to quality and compliance. The company adheres to strict quality control standards and certifications, ensuring that its manufacturing processes meet the highest levels of quality and safety. This dedication to quality has earned {Company Name} the trust and confidence of its clients, many of whom rely on its services for their most critical and sensitive manufacturing needs.In recent news, {Company Name} has announced a strategic partnership with a global leader in {specific industry} to expand its manufacturing capabilities. This partnership will enable {Company Name} to leverage its expertise and resources to support the production of {specific products or components}, further solidifying its position as a prominent contract manufacturer in the industry.As the demand for contract manufacturing services continues to grow, {Company Name} is well-positioned to meet the needs of businesses seeking reliable and efficient manufacturing solutions. Its dedication to quality, innovation, and customer satisfaction sets it apart as a trusted partner for businesses looking to outsource their production needs.In conclusion, {Company Name} is a leading contract manufacturer with a proven track record of delivering high-quality manufacturing solutions. Its commitment to innovation, flexibility, and quality has made it a top choice for businesses across various industries. With a strategic partnership in place and a focus on continuous improvement, {Company Name} is poised to remain a prominent player in the contract manufacturing industry for years to come.

10 Best Board Games for Family Game Night

Layer Board, a global leader in the production of high-quality sustainable paper-based packaging solutions, has announced a new initiative to further enhance its commitment to sustainability and reduce its environmental impact. This initiative comes in response to growing concerns about the environmental impact of the packaging industry and the increasing demand for eco-friendly alternatives.Layer Board has a long-standing commitment to sustainability and the environment, with a focus on reducing its carbon footprint and minimizing waste. The company has invested heavily in research and development to create innovative packaging solutions that are not only environmentally friendly but also cost-effective and efficient.This new initiative builds on Layer Board's existing efforts to promote sustainability within the packaging industry and will see the company implementing a range of measures to further reduce its environmental impact. These measures include a significant investment in renewable energy sources, such as solar and wind power, to power its production facilities. Layer Board has also committed to reducing its water consumption and minimizing waste through improved production processes and the use of recycled materials.In addition to these internal measures, Layer Board is also working closely with its suppliers and customers to promote sustainable practices throughout the entire supply chain. The company is encouraging its suppliers to adopt environmentally friendly packaging materials and is working with its customers to develop packaging solutions that are both effective and sustainable.Layer Board's commitment to sustainability extends beyond its production processes and supply chain to include active engagement with local communities and environmental organizations. The company is a strong advocate for conservation and environmental protection and actively supports initiatives to protect natural habitats and ecosystems."We are committed to making a positive impact on the environment and believe that sustainable practices are not only essential for our business but also for the planet," said a spokesperson for Layer Board. "Through our ongoing efforts to reduce our environmental impact, we aim to set a new standard for sustainability within the packaging industry and inspire others to follow suit."Layer Board's new sustainability initiative is part of the company's broader corporate responsibility strategy, which encompasses a range of social and environmental initiatives. The company is committed to operating in a responsible and ethical manner, and this commitment is reflected in its approach to sustainability and environmental protection.As a global leader in the packaging industry, Layer Board recognizes the importance of taking proactive measures to address environmental concerns and is dedicated to being at the forefront of sustainable practices. By investing in renewable energy, reducing its water consumption, and promoting sustainable packaging solutions, Layer Board is setting a powerful example for the industry and demonstrating its commitment to making a positive impact on the planet.In summary, Layer Board's new sustainability initiative represents a significant step forward in the company's ongoing commitment to environmental responsibility. Through a combination of internal measures, supply chain engagement, and community involvement, the company is demonstrating its dedication to reducing its environmental impact and promoting sustainable practices within the packaging industry. With this initiative, Layer Board is setting a new standard for sustainability and leading the way towards a more environmentally friendly future.

Top Pcb Company Makes Strides in Advancing Technology

In the world of electronic manufacturing, PCB (printed circuit board) companies play a crucial role in creating the backbone of countless electronic devices we use in our daily lives. One such company that has been making waves in the industry is {}.{} is a leading PCB company with a strong focus on innovation, quality, and customer satisfaction. With state-of-the-art facilities and a team of experienced professionals, the company has been at the forefront of delivering high-quality PCB solutions to a wide range of industries including telecommunications, automotive, medical devices, consumer electronics, and more.The company has built a strong reputation for its ability to meet the diverse needs of its customers by offering a comprehensive suite of PCB services including prototype PCB assembly, PCB fabrication, PCB design, and PCB layout. In addition, {} prides itself on its ability to provide quick turnaround times without compromising on quality, making it a preferred partner for many leading electronic manufacturers.One of the key differentiators for {} is its commitment to continuous improvement and investment in cutting-edge technology. The company understands the rapidly evolving nature of the electronic industry and has thus made significant investments in advanced equipment and software to ensure that it stays ahead of the curve. This commitment to innovation has allowed {} to stay at the forefront of the industry and consistently deliver superior PCB solutions to its customers.Furthermore, {} is dedicated to maintaining the highest standards of quality and reliability in all its products. The company is certified to ISO standards and adheres to strict quality control measures throughout the manufacturing process. This dedication to quality has earned {} the trust and confidence of its customers, who rely on the company to deliver PCB solutions that meet their exact specifications and requirements.In addition to its technical prowess, {} also places a strong emphasis on customer satisfaction. The company understands the importance of building strong relationships with its customers and works closely with them to understand their unique needs and challenges. This customer-centric approach has been fundamental to {}'s success and has resulted in long-standing partnerships with many of its clients.Looking ahead, {} is well-positioned to capitalize on the growing demand for high-quality PCB solutions. With an unwavering commitment to innovation, quality, and customer satisfaction, the company is poised to continue its upward trajectory in the electronic manufacturing industry. As the demand for electronic devices continues to rise, {} will play a pivotal role in enabling the development of cutting-edge technologies that power our modern world.To learn more about {} and its comprehensive range of PCB services, visit their website at www.{}.com or contact their team directly for more information.With its dedication to quality, innovation, and customer satisfaction, {} is set to remain a leading force in the PCB industry for years to come.

The Step-by-Step Guide to PCB Assembly Process

With a mission to provide cutting-edge PCB assembly solutions that cater to the needs of businesses across industries, Smt Pcb Assembly Process is proud to offer high-quality PCB assembly services that have received numerous accolades from clients around the world. The company has built a solid reputation for delivering world-class solutions designed to deliver the highest levels of durability, reliability, and performance.At Smt Pcb Assembly Process, quality is the top priority, and the company is committed to providing clients with the most advanced PCB assembly services that meet international standards. The company has invested heavily in the latest technology, tools, and equipment needed to achieve high levels of quality control and monitoring at every stage of the assembly process.One of the key strengths of Smt Pcb Assembly Process is its team of highly experienced professionals, who are committed to ensuring that customers get the best possible service and support. The team comprises industry experts who have many years of experience in PCB design, manufacturing, and assembly, and are always on hand to offer guidance, advice, and solutions to any problems clients encounter during the assembly process.Smt Pcb Assembly Process's PCB Assembly process is designed to cater to a wide range of clients, from small startups to large multinationals. The company's capabilities include the assembly of prototypes, low volume production, and high-volume production runs from 100,000 to 10 million units. With a diverse range of clients across various industries, Smt Pcb Assembly Process's team of experts has amassed an in-depth knowledge of the assembly processes involved in the production of complex projects involving printed circuit boards.Smt Pcb Assembly Process has invested in state-of-the-art equipment that enables it to produce PCB designs faster and more precisely than ever before. The company's assembly line features cutting-edge tools, including SMT placement machines, automatic optical inspection machines, and reflow ovens that ensure consistent, high-quality assembly.One of the unique features of Smt Pcb Assembly Process is its advanced testing process to detect faults in PCBs before they are shipped to clients. The company has developed a range of testing methods, including the use of In-circuit Testing (ICT) and Flying Probe testing, that ensure that all PCBs meet the highest standards of quality control.Despite its advanced capabilities and reputation for delivering high-quality PCB assembly services, Smt Pcb Assembly Process is committed to providing cost-effective solutions to its clients. The company has optimized its processes to minimize operational costs while ensuring that quality is never compromised. This enables clients to get the best possible quality at the best possible prices.In conclusion, Smt Pcb Assembly Process is a reputable PCB assembly services provider that stands out for its commitment to quality, speed, and reliability. The company's advanced assembly capabilities, cutting-edge tools, and experienced team of professionals make it a top choice for businesses across industries looking to produce high-quality printed circuit boards. With a focus on customer satisfaction and cost-effectiveness, Smt Pcb Assembly Process is poised to continue delivering world-class PCB assembly services to clients around the world.

Leading Electronics Supplier Launches Innovative Flexible Printed Circuits

Fpc Electronics Acquires Technology Company to Strengthen Its Capabilities in the Electronics IndustryLeading electronics manufacturer, Fpc Electronics, announced today that they have acquired a technology company in order to enhance their capabilities in the electronics industry. The acquisition will enable Fpc Electronics to expand their product offerings and grow their market share.The name of the technology company was not disclosed, but Fpc Electronics stated that the acquisition was a strategic move to improve their position in the market. The acquisition will help Fpc Electronics to accelerate their innovation and bring new products to market faster.Fpc Electronics is a leading manufacturer of flexible printed circuits (FPC) and rigid-flex circuits. With over 15 years of experience in the industry, Fpc Electronics has become a trusted partner for customers across a variety of industries, including automotive, medical, and telecommunications.“We are very excited about this acquisition and what it means for our company,” said the CEO of Fpc Electronics. “The technology company we acquired has a strong reputation for innovation and has developed some impressive new technologies that will help us to improve our products and services.”The acquisition will also help Fpc Electronics to expand their manufacturing capabilities. The technology company has state-of-the-art manufacturing facilities that will enable Fpc Electronics to increase production and improve efficiency. This will ultimately help Fpc Electronics to better serve their customers and meet the growing demand for their products.“With this acquisition, we are positioning ourselves for continued growth and success in the electronics industry,” added the CEO. “We believe that the combination of our expertise in FPC and rigid-flex circuits, along with the new technologies that we have acquired, will enable us to provide our customers with even more value.”Fpc Electronics has been a pioneer in the electronics industry, introducing new technologies and products that have helped to shape the industry. With this acquisition, Fpc Electronics is once again demonstrating their commitment to innovation and their dedication to meeting the needs of their customers.“We are proud to be a leader in the electronics industry and we are excited about the future of our company,” said the CEO. “We believe that this acquisition will help us to achieve even greater success in the years ahead.”The acquisition is expected to be completed by the end of the year, subject to regulatory approvals. Following the completion of the acquisition, Fpc Electronics will begin integrating the new technologies into their products and services. They will also work to increase production capabilities and improve efficiency in their manufacturing processes.Overall, this acquisition is a significant milestone for Fpc Electronics and a positive development for the electronics industry. With this acquisition, Fpc Electronics is well positioned to continue driving innovation, expanding their market share, and delivering value to their customers.

Customized Printed Circuit Board Manufacturer – All You Need to Know About Prototypes

Proto Pcb, a leading manufacturer of printed circuit boards, has recently announced a major breakthrough in the field of electronic component manufacturing. The company, known for its innovative and cutting-edge technologies, has developed a revolutionary new process that promises to transform the way printed circuit boards are produced. This development represents a significant advancement in the industry and has the potential to greatly impact the electronic component manufacturing supply chain.Proto Pcb has been a key player in the electronic component manufacturing industry for over two decades. The company has consistently demonstrated its commitment to innovation and has a track record of developing state-of-the-art technologies that push the boundaries of what is possible in the field.The new process developed by Proto Pcb is a game-changer in the printed circuit board manufacturing industry. This innovative method promises to revolutionize the way printed circuit boards are produced, significantly reducing production costs and increasing efficiency. By streamlining the manufacturing process, Proto Pcb expects to deliver higher quality products at a faster pace, ultimately benefiting consumers and the industry as a whole.This breakthrough is the result of years of research and development by Proto Pcb's team of highly skilled engineers and scientists. The company has invested significant resources into developing this new process, recognizing the potential impact it could have on the industry. The successful development of this revolutionary manufacturing process is a testament to Proto Pcb's dedication to pushing the boundaries of what is possible in electronic component manufacturing.The implications of this breakthrough are far-reaching. By introducing this new process, Proto Pcb is poised to disrupt the traditional methods of printed circuit board manufacturing. The company's innovative approach has the potential to set a new standard for electronic component manufacturing, leading to a more efficient and cost-effective supply chain.In addition to the potential impact on the industry, this breakthrough is also expected to benefit consumers. With a more efficient and cost-effective manufacturing process, Proto Pcb will be able to deliver higher quality printed circuit boards at a more competitive price. This could lead to cost savings for manufacturers and ultimately result in more affordable electronic devices for consumers.Proto Pcb's commitment to innovation and continuous improvement has been a driving force behind this breakthrough. The company has a long history of pioneering new technologies and this latest development is a testament to its ongoing efforts to stay at the forefront of the electronic component manufacturing industry.As a leader in the field, Proto Pcb has a reputation for delivering high-quality products and providing exceptional customer service. The company's dedication to excellence has earned it a strong reputation and a loyal customer base. With this latest breakthrough, Proto Pcb is once again demonstrating its commitment to delivering innovative solutions that meet the evolving needs of the industry.The impact of this breakthrough on the electronic component manufacturing industry is expected to be profound. Proto Pcb's new process has the potential to transform the way printed circuit boards are produced, leading to a more efficient and cost-effective supply chain. This development is a significant step forward for the industry and further solidifies Proto Pcb's position as a leader in electronic component manufacturing.In conclusion, Proto Pcb's groundbreaking new manufacturing process represents a major advancement in the field of electronic component manufacturing. This innovative approach has the potential to transform the industry, leading to more efficient and cost-effective production of printed circuit boards. With this latest breakthrough, Proto Pcb continues to demonstrate its commitment to innovation and excellence, setting a new standard for the electronic component manufacturing industry.