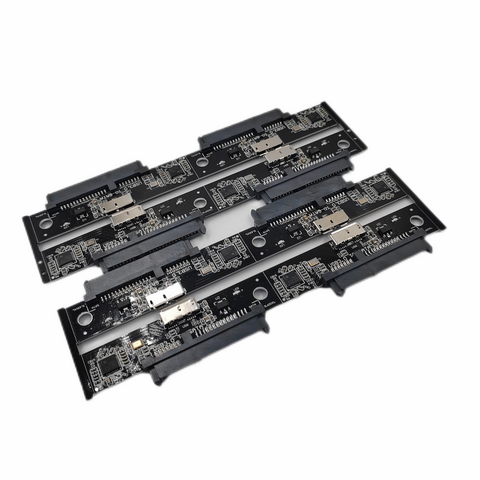

Enhance Your Product Development with High-Quality PCB Prototype Fabrication

By:Admin

In this regard, [Company Name] stands out as a leading provider of PCB prototype fabrication services. The company specializes in providing high-quality, quick-turn PCB prototypes to meet the specific requirements of their clients.

[Company Name] has a state-of-the-art facility equipped with advanced machinery and equipment, enabling them to deliver top-notch PCB prototypes with exceptional precision and accuracy. The company's team of skilled engineers and technicians work tirelessly to ensure that each prototype meets the highest standards of quality and reliability.

The company's dedication to delivering top-quality PCB prototypes has garnered them a strong reputation in the industry. Their commitment to customer satisfaction and their ability to meet tight deadlines has made them a preferred choice for many businesses and individuals looking for reliable PCB prototype fabrication services.

With a focus on innovation and continuous improvement, [Company Name] has positioned itself as a leader in the PCB prototype fabrication industry. The company is constantly investing in the latest technologies and equipment to enhance their capabilities and stay ahead of the competition.

One of the key factors that set [Company Name] apart from other PCB prototype fabrication service providers is their attention to detail and commitment to excellence. They understand the importance of delivering flawless prototypes that meet the specific requirements of their clients, and they go above and beyond to ensure that every prototype meets the highest standards of quality and reliability.

In addition to their technical expertise, [Company Name] also offers excellent customer service. Their team is dedicated to providing personalized support and guidance to clients throughout the prototype fabrication process. Whether it's a simple prototype or a complex multi-layered PCB, the company's experts are always on hand to provide assistance and ensure that the final product meets the client's expectations.

The company's extensive experience in the PCB prototype fabrication industry has enabled them to work with a wide range of clients from various sectors, including electronics, aerospace, automotive, medical, and more. Their ability to cater to diverse industries and deliver tailored solutions has further cemented their position as a trusted and reliable PCB prototype fabrication service provider.

Looking ahead, [Company Name] is committed to staying at the forefront of the PCB prototype fabrication industry. They plan to continue investing in cutting-edge technologies and expanding their capabilities to meet the evolving needs of their clients. The company also aims to further strengthen its position in the market by maintaining its unwavering focus on quality, innovation, and customer satisfaction.

In conclusion, [Company Name] is a reputable and reliable provider of PCB prototype fabrication services. With their state-of-the-art facility, skilled team, and commitment to excellence, they have established themselves as a leader in the industry. Their ability to deliver high-quality, quick-turn prototypes tailored to the specific requirements of their clients sets them apart from other service providers. As they continue to invest in innovation and expansion, [Company Name] is poised to remain a top choice for businesses and individuals seeking top-notch PCB prototype fabrication services.

Company News & Blog

Latest Power Circuit Board Technology Revealed in News Report

Power Circuit Board, a leading provider of high-quality circuit board solutions, has recently announced a breakthrough in the development of advanced power circuit boards. With a strong focus on innovation and technology, Power Circuit Board has been at the forefront of creating cutting-edge solutions for a wide range of industries.The new power circuit boards developed by Power Circuit Board are designed to meet the increasing demand for higher power density and efficiency in a variety of applications. These innovative circuit boards are set to revolutionize the power electronics industry by offering superior performance and reliability.Power Circuit Board's advanced power circuit boards have been engineered to deliver exceptional power density, enabling them to handle higher power levels without compromising on efficiency. This makes them ideal for use in high-power applications such as electric vehicles, renewable energy systems, industrial equipment, and telecommunications infrastructure.One of the key features of Power Circuit Board's advanced power circuit boards is their ability to offer superior thermal management. This is achieved through state-of-the-art design and advanced materials, allowing for efficient heat dissipation and thermal stability. As a result, these circuit boards are able to operate at higher power levels while maintaining optimal performance and reliability.In addition to their high power density and superior thermal management, Power Circuit Board's advanced power circuit boards also boast advanced protection features, ensuring the safety and longevity of the electronic systems they power. These protection features include overcurrent protection, overvoltage protection, and overtemperature protection, providing peace of mind for users and manufacturers alike.Furthermore, Power Circuit Board's commitment to quality and reliability is reflected in the stringent testing and quality control measures implemented throughout the manufacturing process. This ensures that the advanced power circuit boards meet the highest standards of performance and durability, making them an ideal choice for demanding applications in various industries.Power Circuit Board's dedication to innovation and excellence has solidified its position as a trusted partner for companies seeking high-quality circuit board solutions. With a team of skilled engineers and industry experts, the company continues to push the boundaries of what is possible in power electronics, paving the way for the next generation of advanced power circuit boards."We are excited to introduce our latest line of advanced power circuit boards, which represent a significant leap forward in power electronics technology," said a spokesperson for Power Circuit Board. "These circuit boards have been designed to address the evolving needs of industries that demand higher power density, efficiency, and reliability. We are confident that our advanced power circuit boards will set new benchmarks for performance and quality in the power electronics industry."In conclusion, Power Circuit Board's groundbreaking advancements in power circuit board technology are set to have a transformative impact on numerous industries. With their focus on innovation, quality, and reliability, Power Circuit Board remains a leader in providing high-quality circuit board solutions for a wide range of applications. As the demand for higher power density and efficiency continues to grow, Power Circuit Board's advanced power circuit boards are well-positioned to meet and exceed the evolving needs of the market.

Latest News Update: Important Updates on STM Revealed

In recent news, STM has partnered with a leading semiconductor company to expand its offerings and enhance its leadership position in the semiconductor industry. This new partnership will allow STM to offer innovative and cutting-edge solutions for a variety of applications.STM, a global leader in semiconductor manufacturing and solutions, focuses on creating intelligent and energy-efficient technologies. By combining its expertise with the expertise of this new partner, STM is poised to offer state-of-the-art solutions that will drive growth and innovation across the semiconductor industry.As part of the new agreement, STM will be able to incorporate the partner’s advanced technologies into its products and services. This will help STM continue to provide cutting-edge solutions that meet the evolving needs of its customers.It is not surprising that STM has identified the need to collaborate with a leading partner to leverage advanced technologies in its offerings. In today's rapidly changing technological landscape, partnerships and collaborations within the industry are essential for companies that want to remain competitive.This partnership is yet another example of how STM has continuously evolved and adapted to the rapidly changing needs of the semiconductor industry. STM has always been at the forefront of innovation and has consistently demonstrated its ability to anticipate future trends and market demands.STM's portfolio of products and services includes a wide range of solutions for the Internet of Things (IoT), automotive applications, industrial automation, and more. With this new partnership, STM is poised to further expand its offerings to better serve its customers across various industries.As STM continues to lead the way in the semiconductor industry, it is also focused on sustainability and corporate social responsibility. STM is committed to reducing its environmental footprint through its products and operations. The company has set ambitious goals for reducing energy consumption, greenhouse gas emissions, and waste.In addition to sustainability, STM is committed to creating a positive impact on society. The company is focused on creating innovative solutions that improve people's lives, such as increasing road safety, enabling smart homes and cities, and enhancing healthcare technologies. With this new partnership, STM is poised to create even more positive impact through its innovative solutions.This partnership is also expected to have a positive impact on the semiconductor industry as a whole. By collaborating and sharing expertise with leading partners, STM is contributing to the greater good of the industry. The partnership is likely to spark new ideas, breakthroughs, and advancements that will benefit all stakeholders.In conclusion, STM's partnership with a leading semiconductor company is a significant development for the industry. This collaboration will enable STM to offer cutting-edge solutions that meet the evolving needs of its customers. It is also in line with the company's commitment to sustainability and creating a positive impact on society. With this new partnership, STM is poised to continue leading the way in the semiconductor industry.

Latest Developments in the Game Console Control Board Industry: What You Need to Know!

Title: Next-Generation Game Console Control Board Unveiled by Prominent Gaming CompanyIntroduction:In a bid to revolutionize the gaming industry, a well-known gaming company has revealed its latest creation - the next-generation game console control board. This state-of-the-art innovation aims to provide gamers with an unparalleled gaming experience, boasting cutting-edge technology and enhanced features. With its sleek design and advanced functionality, this control board promises to redefine the way players interact with their favorite games. Let's dive deeper into the features and potential impact of this groundbreaking invention.1. Enhanced Connectivity and Compatibility:The newly unveiled game console control board ensures seamless connectivity and compatibility across various gaming platforms and devices. Its versatile design supports both wired and wireless connections, allowing gamers the freedom to choose their preferred gaming setup. With its support for the latest Bluetooth technology, players can effortlessly connect the control board to compatible devices, including smartphones and laptops. The control board also integrates with popular gaming consoles, ensuring an immersive gaming experience universally.2. Advanced Precision and Responsiveness:Precision and responsiveness are integral to every gaming experience, and the control board's cutting-edge technology addresses these requirements. Equipped with high-precision analog sticks and pressure-sensitive buttons, this control board offers gamers enhanced control over their actions within games. The increased sensitivity of the control board ensures that players' every movement and action is accurately reflected on-screen, elevating the overall gameplay experience to new heights.3. Customizable Layout and Personalization:Recognizing the diverse preferences of gamers, the game console control board provides extensive customization options. Players can now personalize their control board layout to suit their unique gaming style, offering them a level of comfort and familiarity like never before. The control board allows users to reassign buttons, adjust sensitivity, and even create personalized macros, thus granting players full control over their gaming experience.4. Immersive Audio and Visual Integration:The game console control board incorporates advanced audio and visual integration, enhancing players' gaming immersion. With built-in high-definition audio technology, the control board delivers crisp and realistic sound effects, ensuring players can fully immerse themselves in the game's environment. Furthermore, the control board effortlessly syncs with compatible VR headsets, elevating the player's visual experience to encompass an entirely new dimension of realism.5. Streamlined User Interface and Accessibility Features:The company behind this revolutionary control board understands the value of a streamlined user interface. To enhance user experience, the control board features a user-friendly interface that simplifies navigation and access to various settings. Additionally, the control board integrates accessibility features that cater to gamers with different physical abilities, ensuring inclusivity within the gaming community.Conclusion:The advent of the next-generation game console control board promises to redefine the realms of gaming and create a new era of immersive experiences for gamers worldwide. Its enhanced connectivity, advanced precision, and customizable features allow players to delve deeper into their favorite games with unrivaled control. By integrating cutting-edge audio and visual technologies, the control board ensures an unmatched level of immersion. With its streamlined user interface and accessibility features, the control board caters to a wider audience and fosters inclusivity within the gaming community. As gaming continues to evolve, this groundbreaking control board is set to play a key role in shaping the future of the gaming industry.

Efficient Smt Pcb Assembly Process: Everything You Need to Know

Smt Pcb Assembly Process Improves Efficiency and Quality for {Company}{Company} is a leading provider of electronic manufacturing services, specializing in Smt Pcb assembly. The company has recently invested in new equipment and technology to enhance its assembly process, aiming to improve efficiency and quality for its clients.The Smt Pcb assembly process is a crucial step in electronic manufacturing, as it involves placing and soldering surface mount components onto printed circuit boards. This process requires precision and accuracy to ensure that the final product meets the highest quality standards.{Company} has always been dedicated to staying at the forefront of technological advancements in electronic manufacturing. With the recent investment in new Smt Pcb assembly equipment, the company has taken its commitment to excellence to the next level.One of the key improvements in the new Smt Pcb assembly process is the use of advanced pick-and-place machines. These machines are equipped with state-of-the-art vision systems and robotics, allowing for faster and more accurate placement of components onto the circuit boards. This upgrade greatly enhances the efficiency of the assembly process, leading to shorter lead times for clients without compromising on quality.Furthermore, {Company} has implemented advanced soldering techniques to ensure the reliability and durability of the assembled Pcb boards. The company uses advanced reflow ovens and selective soldering equipment to achieve optimal solder joints, minimizing the risk of defects and ensuring the long-term performance of the electronic devices.In addition to equipment upgrades, {Company} has also focused on enhancing its quality control procedures in the Smt Pcb assembly process. The company has implemented rigorous inspection and testing protocols to detect and address any potential issues early in the assembly process, preventing defects and ensuring the highest quality of the final products.The investment in the Smt Pcb assembly process aligns with {Company}'s mission to provide its clients with the best possible solutions for their electronic manufacturing needs. The company understands the importance of delivering products that meet the highest quality standards, and the enhanced assembly process is a testament to its dedication to excellence.Clients of {Company} can expect to benefit from the improvements in the Smt Pcb assembly process, as they will experience faster turnarounds, higher quality, and more reliable electronic products. The company is confident that the upgrades will further solidify its position as a trusted partner in the electronic manufacturing industry.The investment in the Smt Pcb assembly process is just one example of {Company}'s continuous efforts to innovate and improve its services. With a team of skilled professionals and a strong focus on technology and quality, the company remains committed to exceeding the expectations of its clients and setting new standards in electronic manufacturing.As the demand for high-quality electronic products continues to grow, {Company} is well-positioned to meet the needs of its clients and adapt to the ever-changing market dynamics. The company's dedication to investing in the latest technology and process improvements ensures that it remains a leader in the electronic manufacturing industry.In conclusion, the recent investment in the Smt Pcb assembly process at {Company} has brought about significant improvements in efficiency and quality. With advanced equipment and technology, the company has strengthened its capabilities and positioned itself as a reliable partner for electronic manufacturing needs. The enhancements in the assembly process are a testament to {Company}'s commitment to excellence and its dedication to exceeding client expectations.

Efficient SMT Assembly Process: Streamlining Production for Optimal Results

Smt Assembly Process Revolutionizes Electronics Manufacturing IndustryIn an industry that is constantly evolving, companies are always seeking new ways to improve their manufacturing processes to stay ahead of the competition. One such company, based in {}, has recently introduced an innovative method called Surface Mount Technology (SMT) assembly process. This groundbreaking technology is set to revolutionize the electronics manufacturing industry.With the SMT assembly process, components are mounted directly onto the surface of a printed circuit board (PCB). This method eliminates the need for through-hole technology, where components are mounted by inserting leads into drilled holes on the board. Instead, SMT components are soldered onto the board using specialized machines, which saves production time and reduces costs.This new process has caught the attention of several companies in the electronics manufacturing industry due to its numerous advantages. One major benefit is the increased precision and accuracy achieved through SMT assembly. The components are placed precisely in predetermined locations, ensuring the reliability and functionality of the final product. This level of precision was previously difficult to achieve with through-hole technology.Furthermore, the SMT assembly process allows for miniaturization of electronic devices. As SMT components are smaller than their through-hole counterparts, companies can design and manufacture smaller, more compact electronic products. This is especially important in industries such as consumer electronics and medical devices, where portability and size are significant factors.Moreover, the SMT assembly process enables a higher degree of automation in production. By utilizing specialized machines, companies can streamline their manufacturing processes and increase production capacity. This automation not only improves efficiency but also reduces the potential for human error, leading to higher quality products.The environmental impact of electronic manufacturing is another critical consideration in today's world. Fortunately, the SMT assembly process is more environmentally friendly compared to through-hole technology. SMT components consume fewer materials, generate less waste, and use lead-free solders. This reduction in waste and hazardous materials contributes to a greener manufacturing process, aligning with global environmental standards.With numerous advantages in speed, precision, miniaturization, automation, and environmental impact, it's no wonder that more and more companies are adopting the SMT assembly process. One such company leading the way in implementing this revolutionary method is {}. Combining cutting-edge technology with their deep industry experience, they have successfully transformed the manufacturing process for electronics.{} is committed to providing the highest quality SMT assembly services to their clients. They understand the importance of staying at the forefront of technology in a rapidly evolving industry. With state-of-the-art equipment and a team of skilled professionals, they ensure that every product manufactured using the SMT assembly process meets the highest standards of quality and reliability.The company's dedication to customer satisfaction is unparalleled. They work closely with their clients to understand their unique requirements and provide tailored solutions that meet their specific needs. From component sourcing and PCB design to assembly and testing, {} offers a comprehensive range of services, all utilizing the innovative SMT assembly process.As the electronics manufacturing industry continues to grow and evolve, adopting cutting-edge technologies like the SMT assembly process is vital for remaining competitive. With its numerous advantages, this revolutionary method is set to transform the industry, enabling companies to produce higher quality, more compact, and environmentally friendly electronic devices.In a world where technology is advancing at an unprecedented pace, companies must adapt and embrace innovation to stay ahead. With the introduction of the SMT assembly process, {} is leading the charge in revolutionizing the electronics manufacturing industry, paving the way for a more efficient, precise, and sustainable future.

Essential Guide to Understanding PCB Board Schematic Designs: Simplified & Comprehensive Explanation

PCB Board Schematic – The Way Forward in Electronic ManufacturingThe demand for electronic devices has skyrocketed to an unprecedented level in the last decade. This, in turn, gave rise to the electronic manufacturing industry, which has rapidly evolved to produce high-quality hardware for use in devices such as smartphones, laptops, and televisions, among others.One essential component in the electronic manufacturing process is the Printed Circuit Board (PCB). It is a board that connects and houses electronic components such as capacitors, resistors, and microchips. A PCB comes in various types and is essential in the design of electronic devices.The PCB functions by providing an electrical pathway for the components to connect, communicate, and power each other. It also ensures the stability and durability of the device. To achieve optimal results, every PCB design goes through a process called schematic capture.Schematic capture is the process of creating a blueprint of the PCB design, which is fundamental in ensuring that all the components are in the right position and orientation. This process also makes sure that a particular design meets certain electrical and mechanical specifications.With the importance of schematic capture, PCB Board Schematic (need remove brand name) has become the go-to partner for many electronics manufacturers. They provide high-quality schematic capture services tailored to meet the specific specs of each client. The company is committed to delivering the best PCB services and ensuring that clients achieve their product designs' desired functionalities.The PCB Board Schematic (need remove brand name) company has an experienced team of engineers, designers, and project managers who work tirelessly to ensure that all clients' specifications are met. Their team is highly skilled in both analog and digital electronic designs, and they have a wealth of knowledge in creating schematics for various projects.PCB Board Schematic (need remove brand name) understands the importance of using the latest design software and technology in the electronic industry. They use the latest software such as Altium Designer and CADSTAR to ensure the accuracy and efficiency of the schematic capture process. This approach has not only enabled the company to stay ahead of the competition but also made their services affordable and accessible to clients from all over the world.Besides schematic capture, PCB Board Schematic (need remove brand name) also offers other PCB design services such as routing, manufacturing, and assembly. They have state-of-the-art manufacturing machines that ensure the highest quality, precision, and consistency in all their designs.PCB Board Schematic (need remove brand name)'s success is not only attributed to the quality of their services but also their commitment to customer satisfaction. They value every client and aim to build a long-term and transparent relationship with each one of them.In conclusion, the electronic manufacturing industry is growing each day, and the need for high-quality PCBs is on the rise. PCB Board Schematic (need remove brand name) is committed to providing the best PCB services and ensuring that every client achieves the desired functionalities of their product designs. Their experienced team, use of the latest technology, and commitment to customer satisfaction make them the go-to partner for all your PCB schematic capture and design projects.

Understanding the PCB Development Process: From Design to Manufacturing

PCB Development Process for Manufacturing Advanced Technology ProductsThe PCB development process is a crucial step in the production of advanced technology products. PCB, or printed circuit board, serves as the foundation for connecting electronic components in a multitude of devices, from smartphones and computers to medical equipment and automotive systems. The development process requires careful planning, precise execution, and thorough testing to ensure the reliability and functionality of the final product.In this regard, {Company Name} is a leading manufacturer specializing in PCB development and production for various industries. The company has established a strong reputation for delivering high-quality PCB solutions that meet the demanding requirements of modern technology products. With state-of-the-art facilities and a team of experienced engineers, {Company Name} is committed to providing innovative PCB development processes that drive the advancement of technology.The PCB development process at {Company Name} begins with a comprehensive analysis of the customer's requirements and specifications. This initial phase involves close collaboration with the client to understand the intended application of the PCB and its performance expectations. Whether it's a complex multilayer PCB for a sophisticated electronic device or a simple single-layer board for a basic application, {Company Name} employs a customized approach to meet the unique needs of each project.Once the requirements are defined, the PCB design phase commences. {Company Name} utilizes advanced design software and simulation tools to create a schematic layout that incorporates the necessary components and connectivity for the specific application. The design team at {Company Name} leverages their expertise to optimize the layout for signal integrity, power distribution, and thermal management, ensuring the overall performance and reliability of the PCB.Upon finalizing the design, the development process transitions to the prototyping stage. {Company Name} utilizes rapid prototyping techniques to quickly produce a physical prototype of the PCB for testing and validation. This iterative process allows for the identification of any design flaws or performance issues, which can be addressed before moving into full-scale production. By actively engaging in prototyping, {Company Name} ensures that the final PCB meets the highest standards of quality and functionality.The manufacturing phase of the PCB development process is where {Company Name}'s expertise truly shines. With a focus on precision and efficiency, the company utilizes advanced manufacturing equipment and processes to fabricate the PCB according to the approved design. Whether it's the precise application of copper traces, the addition of vias and pads, or the implementation of specialized surface finishes, {Company Name} employs stringent quality control measures to maintain consistency and accuracy throughout the manufacturing process.To ensure the reliability and durability of the PCB, {Company Name} conducts thorough testing and inspection procedures. The company utilizes advanced testing equipment to validate the electrical performance, mechanical strength, and environmental resilience of the PCB. From electrical continuity and impedance testing to thermal cycling and vibration testing, {Company Name} enforces a comprehensive testing regime to validate the functionality and durability of the PCB for its intended application.With the PCB development process finalized, {Company Name} delivers the finished product to its customers with a commitment to excellence. The company's dedication to quality, innovation, and customer satisfaction has positioned it as a trusted partner for numerous industries seeking reliable PCB solutions. Whether it's for consumer electronics, automotive systems, medical devices, or industrial applications, {Company Name} continues to drive the advancement of technology through its exceptional PCB development processes.In conclusion, the PCB development process is an essential aspect of manufacturing advanced technology products, and {Company Name} excels in delivering comprehensive and reliable PCB solutions. With a focus on collaborative design, rapid prototyping, precise manufacturing, and thorough testing, {Company Name} remains at the forefront of PCB development, ensuring the performance and reliability of electronic devices across various industries.

High Quality PCB Assembly Services for Efficient Production

PCB With Assembly Expands Production to Meet Growing Demand in Electronics IndustryWith the rapid advancement of technology, the demand for high-quality printed circuit boards (PCBs) and electronic assembly services is on the rise. In order to meet this increasing demand, () has recently expanded its production capacity and capabilities to better serve the rapidly growing electronics industry.Established in [], () has been a leading provider of PCB and electronic assembly services for over [] years. The company has built a strong reputation for delivering high-quality products and exceptional customer service. With a focus on innovation and continuous improvement, () has consistently adapted to the changing needs of the electronics market, positioning itself as a reliable and trusted partner for clients worldwide.The recent expansion of ()’s production facilities is a strategic move to accommodate the growing demand for PCBs and electronic assembly services. The upgraded facilities are equipped with state-of-the-art machinery and advanced technologies, allowing the company to increase its production capacity and enhance its manufacturing capabilities. This expansion will enable () to deliver a wider range of PCB and electronic assembly solutions, catering to the diverse needs of customers in various industries such as automotive, telecommunications, consumer electronics, and more.In addition to the increased production capacity, () has also strengthened its commitment to quality and efficiency. The company has invested in comprehensive quality control measures and streamlined production processes to ensure the highest level of precision and reliability in every product. By adopting industry-leading standards and best practices, () aims to uphold its reputation as a top-tier provider of PCB and electronic assembly services.Furthermore, ()’s expanded production facilities will enable the company to offer a more comprehensive range of services, including turnkey PCB assembly, prototype development, and full-scale production runs. With a team of experienced engineers and technicians, () is capable of handling complex and intricate projects, providing custom solutions to meet the unique requirements of each client.The expansion of ()’s production capabilities comes at a time when the electronics industry is experiencing unprecedented growth and evolving technological trends. The company is well-positioned to leverage its expanded facilities and expertise to address the increasing demand for high-quality PCBs and electronic assembly services. By staying at the forefront of technological advancements and market dynamics, () is poised to play a pivotal role in shaping the future of the electronics industry.As a customer-centric organization, () remains dedicated to delivering exceptional value to its clients. The company’s expanded production facilities will not only enable it to meet the growing demand for PCB and electronic assembly services but also to offer competitive pricing and shorter lead times, providing customers with a significant advantage in the fast-paced electronics market.In conclusion, ()’s recent expansion of its production capabilities underscores its commitment to delivering high-quality PCB and electronic assembly services to meet the increasing demand in the electronics industry. The company’s investment in advanced technologies and comprehensive quality measures reflects its dedication to excellence and customer satisfaction. With an unwavering focus on innovation and continuous improvement, () is poised to drive the next wave of development in the electronics industry, solidifying its position as a leading provider of PCB and electronic assembly services.

3D Printed Circuit Board (PCB) Printer for Hobbyists: A Complete Guide

Introducing a Revolutionary Hobbyist PCB PrinterIn today’s fast-paced world of innovation and technology, enthusiasts and hobbyists are constantly seeking new and efficient ways to bring their ideas to life. Whether it’s creating a custom circuit board for a new electronic project or designing a prototype for a groundbreaking invention, having the right tools at their disposal is crucial for turning their dreams into reality. That’s where the Hobbyist PCB Printer comes in.Developed by the industry-leading company {}, the Hobbyist PCB Printer is a game-changing device that is designed to make the process of creating professional-grade printed circuit boards (PCBs) accessible to everyone. With its user-friendly interface and powerful features, this innovative printer is poised to revolutionize the way hobbyists and electronics enthusiasts approach PCB design and manufacturing.The Hobbyist PCB Printer is equipped with state-of-the-art technology that enables users to quickly and easily design and produce high-quality PCBs right from the comfort of their own homes or workshops. With its precise printing capabilities, advanced software integration, and seamless workflow, this printer empowers hobbyists to take their projects to the next level without the need for expensive outsourcing or time-consuming manual methods.One of the standout features of the Hobbyist PCB Printer is its intuitive software, which allows users to effortlessly create and customize their PCB designs with a comprehensive suite of tools and functions. From schematics and layout design to component placement and routing, the software provides a seamless platform for hobbyists to bring their ideas to life with precision and accuracy.Additionally, the Hobbyist PCB Printer offers versatile printing options that cater to a wide range of project requirements. Whether it’s a single-layer board for a simple circuit or a multi-layer design for a complex electronic device, this printer can handle the job with ease, giving hobbyists the flexibility they need to bring their vision to fruition.Furthermore, the Hobbyist PCB Printer is designed with convenience and practicality in mind. Its compact and robust construction makes it suitable for any workspace, and its low maintenance requirements ensure that users can focus on their projects without worrying about complicated upkeep or technical issues.By combining cutting-edge technology with user-friendly design, the Hobbyist PCB Printer is set to become a must-have tool for hobbyists, makers, and electronics enthusiasts who are passionate about bringing their ideas to life. With its ability to streamline the PCB design and manufacturing process, this printer is sure to inspire creativity and innovation in the DIY electronics community.As the company behind the Hobbyist PCB Printer, {} is dedicated to empowering individuals to explore their creativity and turn their ideas into reality. With a proven track record of delivering high-quality and reliable solutions for the electronics industry, {} is committed to providing innovative tools and resources that make it easier than ever for hobbyists and enthusiasts to pursue their passions.In conclusion, the Hobbyist PCB Printer is a groundbreaking device that is set to revolutionize the way hobbyists and electronics enthusiasts approach PCB design and manufacturing. With its advanced features, user-friendly interface, and commitment to empowering creativity, this printer is sure to inspire a new wave of innovation in the DIY electronics community. Thanks to the innovative vision and dedication of {}, hobbyists and enthusiasts can look forward to a future filled with endless possibilities for bringing their ideas to life.

Top Electronics Manufacturing Company Provides Quality Products

Smt Electronics Manufacturing, a leading electronic manufacturing services provider, has been making waves in the industry with their cutting-edge technology and innovative solutions. The company has been at the forefront of electronic manufacturing for over a decade and has established a strong reputation for delivering high-quality products to their customers.With state-of-the-art facilities and a team of experienced professionals, Smt Electronics Manufacturing has the capability to handle a wide range of electronic manufacturing needs, from PCB assembly and box build to testing and logistics. The company is known for its commitment to quality and continuous improvement, and their relentless pursuit of excellence has made them a preferred partner for many leading technology companies.Smt Electronics Manufacturing takes pride in their ability to provide customized solutions to meet the unique requirements of their customers. Whether it's a complex project with tight deadlines or a simple assembly job, the company has the expertise and resources to deliver results that exceed expectations. Their focus on innovation and investment in advanced technology has positioned them as a leader in the electronic manufacturing services industry.One of the key strengths of Smt Electronics Manufacturing is their dedicated team of engineers, technicians, and support staff. With a strong emphasis on continuous training and development, the company has nurtured a talented workforce that is capable of tackling the most challenging projects. Their collaborative approach and commitment to customer satisfaction have earned them the trust and loyalty of their clients.In addition to their manufacturing capabilities, Smt Electronics Manufacturing also places a strong emphasis on environmental sustainability and social responsibility. The company is committed to minimizing their environmental impact through efficient processes and responsible waste management practices. They also adhere to strict ethical standards and labor practices to ensure that they operate in a socially responsible manner.As part of their commitment to staying ahead of the curve, Smt Electronics Manufacturing has made significant investments in research and development. The company understands the importance of staying current with the latest technological advancements and continuously seeks to improve their processes and offerings. By staying at the forefront of innovation, Smt Electronics Manufacturing is able to provide their customers with the most advanced and efficient electronic manufacturing solutions.In an ever-evolving industry, Smt Electronics Manufacturing continues to adapt and evolve to meet the changing needs of their customers. Their dedication to quality, innovation, and customer satisfaction has set them apart as a leader in the electronic manufacturing services sector. With a strong track record of success and a commitment to excellence, Smt Electronics Manufacturing is well-positioned to thrive in the fast-paced world of electronic manufacturing.As the company looks to the future, they remain dedicated to providing the best possible service and solutions to their customers. With a focus on continuous improvement and a passion for innovation, Smt Electronics Manufacturing is poised to continue making a significant impact on the electronic manufacturing services industry for years to come.