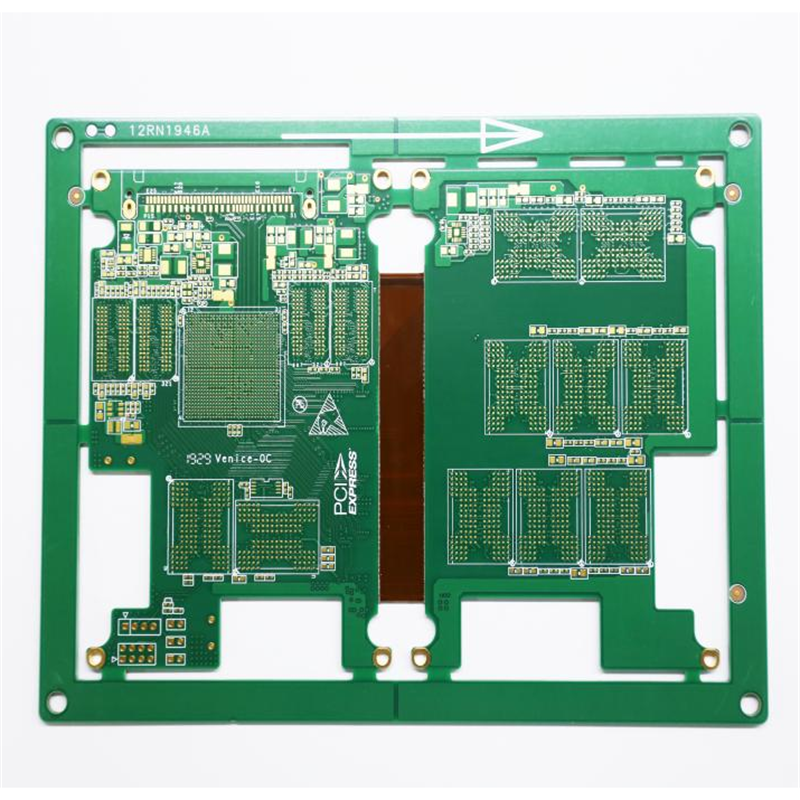

Expert Tips for High Volume PCB Assembly

By:Admin

{Company Name} is a leading provider of electronic manufacturing services (EMS) with a strong focus on high volume PCB assembly. With state-of-the-art facilities and advanced equipment, the company has the capability to handle large-scale production of PCBs for a wide range of applications, including consumer electronics, automotive, industrial equipment, medical devices, and more.

The high volume PCB assembly process at {Company Name} begins with the careful selection of high-quality materials and components to ensure the reliability and performance of the final product. The company works closely with its suppliers to source the best materials and components that meet the specific requirements of each customer's project.

Once the materials and components are procured, the PCB assembly process begins with the placement of the components on the PCBs. {Company Name} utilizes advanced pick-and-place machines and automated assembly lines to achieve high precision and efficiency in the component placement process. These machines are capable of placing thousands of components per hour, ensuring fast and accurate assembly of the PCBs.

After the components are placed, the PCBs undergo a series of soldering processes to securely attach the components to the board. {Company Name} utilizes advanced soldering technologies such as reflow soldering and wave soldering to achieve high-quality solder joints and ensure the reliability of the assembled PCBs.

In addition to the assembly of the PCBs, {Company Name} also provides a range of testing and inspection services to ensure the quality and reliability of the final product. The company uses advanced testing equipment and inspection techniques to detect any defects or issues in the assembled PCBs, allowing for quick and efficient remediation.

One of the key advantages of working with {Company Name} for high volume PCB assembly is its commitment to quality and customer satisfaction. The company has established rigorous quality control processes and standards to ensure that every PCB assembly meets the highest quality and reliability standards.

Furthermore, {Company Name} is dedicated to providing a seamless and efficient manufacturing experience for its customers. The company offers comprehensive project management and logistics support to ensure that the high volume PCB assembly process is completed on time and within budget.

Overall, {Company Name} has proven itself as a reliable and trusted partner for high volume PCB assembly. With its advanced technologies, commitment to quality, and customer-centric approach, the company has established itself as a leader in the electronics manufacturing industry.

In conclusion, high volume PCB assembly is a critical operation in the electronics manufacturing industry, requiring precision, efficiency, and advanced technologies. {Company Name} has excelled in this area, offering high-quality PCB assembly services for a wide range of applications. With its commitment to quality, customer satisfaction, and advanced capabilities, the company has established itself as a trusted partner for high volume PCB assembly.

Company News & Blog

Top PCBA Manufacturer for Quality, Reliable Printed Circuit Board Assemblies

Hua Xing PCBA Limited is a leading provider of high-quality printed circuit board assembly (PCBA) solutions to the electronics industry. With a strong focus on quality, innovation, and customer satisfaction, the company has established a strong reputation as a trusted partner for businesses seeking reliable and efficient PCBA services.The company's state-of-the-art manufacturing facility is equipped with the latest technology and automated equipment to ensure the highest levels of precision and quality in every PCBA project. Hua Xing PCBA Limited takes pride in its ability to deliver cost-effective solutions without compromising on quality, making it a preferred choice for businesses looking to outsource their PCBA needs.In addition to its cutting-edge manufacturing capabilities, the company also offers a comprehensive suite of services to support its clients throughout the entire PCBA process. From design and prototyping to full-scale production and testing, Hua Xing PCBA Limited provides end-to-end solutions that streamline the production process and minimize time to market for its customers.Furthermore, the company places a strong emphasis on adhering to industry standards and best practices to ensure the reliability and performance of its products. By leveraging its expertise and experience, Hua Xing PCBA Limited is able to meet the diverse and evolving requirements of its customers across a wide range of industries, including telecommunications, consumer electronics, medical devices, automotive, and more.Moreover, the company is committed to continuous improvement and invests heavily in research and development to stay ahead of the curve in an ever-changing industry. It also places a strong emphasis on sustainability and environmental responsibility, implementing measures to minimize waste and energy consumption in its operations.With a customer-centric approach, Hua Xing PCBA Limited strives to build long-lasting partnerships with its clients by delivering exceptional products and service. The company's dedicated team of professionals works closely with customers to understand their unique needs and provide tailored solutions that meet and exceed expectations.In addition, the company is known for its commitment to meeting deadlines and providing reliable support to its clients, ensuring that their projects are completed on time and within budget. This level of dedication and reliability has earned Hua Xing PCBA Limited a solid reputation in the industry and has helped it build a loyal and satisfied customer base.In conclusion, Hua Xing PCBA Limited continues to lead the way in the PCBA industry with its unwavering commitment to quality, innovation, and customer satisfaction. By offering advanced manufacturing capabilities, comprehensive services, and a customer-centric approach, the company has solidified its position as a trusted partner for businesses seeking top-notch PCBA solutions. As it continues to grow and evolve, Hua Xing PCBA Limited remains dedicated to exceeding customer expectations and setting new standards of excellence in the industry.

High-Quality Pcb Making Machine for Efficient Production

[Company Name], a leading manufacturer in the electronic industry, has recently unveiled their latest PCB Making Machine. This innovative machine is set to revolutionize the manufacturing process of printed circuit boards with its cutting-edge technology and state-of-the-art features.The PCB Making Machine is designed to provide efficient and precise production of printed circuit boards, which are essential components in electronic devices. With the increasing demand for smaller and more powerful electronic devices, the need for high-quality PCBs has become more crucial than ever. [Company Name]'s new machine aims to address this demand by offering a reliable and advanced solution for PCB manufacturing.The machine boasts a range of impressive features, including high-speed drilling and routing capabilities, precise component placement, and advanced soldering technology. These features not only improve the efficiency of the manufacturing process but also ensure the high quality and reliability of the produced PCBs.In addition, the PCB Making Machine is equipped with intelligent software that allows for easy programming and monitoring of the production process. This user-friendly interface enables operators to easily set up the machine for different PCB designs and quickly make adjustments to optimize the production process.Furthermore, [Company Name] has incorporated advanced quality control systems into the PCB Making Machine to ensure that each PCB meets the highest standards of performance and reliability. This commitment to quality is a testament to the company's dedication to delivering superior products to their customers.The PCB Making Machine is set to make a significant impact in the electronic industry by improving the efficiency and reliability of PCB manufacturing. With its advanced technology and user-friendly design, this machine will help [Company Name] maintain its position as a leader in the electronic manufacturing industry.[Company Name] has a long-standing reputation for delivering high-quality electronic products and solutions. With their commitment to innovation and excellence, they have become a trusted partner for companies seeking reliable and cutting-edge electronic components.In addition to the new PCB Making Machine, [Company Name] offers a wide range of electronic manufacturing services, including PCB assembly, electronic component sourcing, and product design. Their comprehensive capabilities and expertise in the electronic industry have made them a preferred choice for businesses looking for a reliable and experienced electronic manufacturing partner.The unveiling of the PCB Making Machine is a testament to [Company Name]'s ongoing commitment to delivering advanced solutions to the electronic industry. This new machine is a reflection of the company's dedication to innovation and its ability to meet the evolving needs of the electronic market.As the demand for high-quality and efficient PCB manufacturing continues to grow, [Company Name] is well-positioned to lead the industry with their latest innovation. The PCB Making Machine will undoubtedly set a new standard for PCB manufacturing and further solidify [Company Name]'s reputation as a leader in the electronic industry.In conclusion, [Company Name]'s new PCB Making Machine represents a significant advancement in the electronic manufacturing industry. With its cutting-edge technology, advanced features, and user-friendly design, this machine is set to redefine the standards for PCB manufacturing. As [Company Name] continues to drive innovation and excellence in the electronic industry, they are poised to remain a trusted partner for businesses seeking high-quality electronic components and solutions.

Optimizing Flex Circuit Assembly for Improved Performance

Flex Circuit Assembly Company, an industry-leading provider of flexible printed circuit assemblies, has been making waves in the electronic manufacturing services industry with their innovative and cutting-edge solutions. With a strong focus on quality, reliability, and customer satisfaction, the company has built a solid reputation for delivering high-quality flex circuit assemblies that meet the unique needs of their clients.Flex Circuit Assembly Company offers a wide range of services including design, prototyping, manufacturing, and assembly of flexible printed circuit assemblies. Their state-of-the-art facilities and advanced equipment enable them to produce complex and intricate flex circuit assemblies with precision and efficiency. They work closely with their clients to understand their specific requirements and provide customized solutions that meet and exceed their expectations.The company's commitment to excellence is reflected in their rigorous quality control processes and adherence to industry standards. They employ a team of highly skilled and experienced professionals who are dedicated to ensuring that every flex circuit assembly meets the highest standards of performance and reliability. Additionally, Flex Circuit Assembly Company invests in continuous training and development to stay abreast of the latest technologies and advancements in the field, enabling them to deliver innovative and cutting-edge solutions to their clients.One of the key differentiators of Flex Circuit Assembly Company is their ability to offer flexible and scalable manufacturing solutions to accommodate the evolving needs of their clients. Whether it's a small volume prototype or a large-scale production run, the company has the capability to adapt to the project requirements and deliver consistent results. Their flexible manufacturing processes allow for quick turnaround times without compromising on quality, making them a trusted partner for clients across a diverse range of industries.Flex Circuit Assembly Company has a strong track record of successfully delivering flex circuit assemblies for a wide range of applications including medical devices, automotive electronics, consumer electronics, aerospace, and more. Their in-depth industry knowledge and expertise enable them to address the specific challenges and requirements of each sector, providing customized solutions that are tailored to the unique demands of the industry.The company is also committed to sustainability and environmental responsibility, integrating eco-friendly practices into their operations and manufacturing processes. They adhere to strict environmental regulations and work towards minimizing their carbon footprint, ensuring that their operations have minimal impact on the environment.With a customer-centric approach, Flex Circuit Assembly Company places a strong emphasis on building and maintaining long-term relationships with their clients. They prioritize open communication, transparency, and collaboration to ensure that the client's needs are met and their expectations are exceeded. Their dedication to customer satisfaction has earned them a loyal client base and a reputation for being a reliable and trusted partner in the electronic manufacturing services industry.As the demand for flexible printed circuit assemblies continues to grow, Flex Circuit Assembly Company is poised to maintain its position as a leader in the industry. With their unwavering commitment to quality, innovation, and customer satisfaction, the company is well-equipped to address the evolving needs of the market and continue to deliver superior flex circuit assembly solutions to their clients.In conclusion, Flex Circuit Assembly Company stands out as a prominent player in the electronic manufacturing services industry, known for their exceptional quality, reliability, and customer-centric approach. With their comprehensive range of services, advanced capabilities, and commitment to excellence, the company is well-positioned to meet the diverse and evolving needs of clients across various industries.

A Guide to Surface Mount Circuit Boards: What You Need to Know

[Company Logo]FOR IMMEDIATE RELEASE[Date]Contact:[Company Name][Contact Person][Contact Information]Introducing the Cutting-Edge Surface Mount Circuit Board from [Company Name][City, State] - [Company Name], a leading provider of electronic components and solutions, is proud to announce the launch of the latest addition to their product line - the state-of-the-art Surface Mount Circuit Board. This innovative new product represents a significant advancement in circuit board technology, providing customers with high-performance and reliable solutions for their electronic applications.The Surface Mount Circuit Board from [Company Name] is designed to meet the increasing demand for smaller and more efficient electronic devices. With its compact size and advanced features, this circuit board is ideal for a wide range of applications, including consumer electronics, automotive systems, medical devices, and industrial equipment."We are excited to introduce our new Surface Mount Circuit Board to the market," said [Spokesperson], [Title] at [Company Name]. "This product showcases our commitment to innovation and our dedication to providing our customers with the best possible solutions for their electronic needs."The Surface Mount Circuit Board is engineered to deliver superior performance and reliability. It features advanced materials and technologies that enhance its durability and lifespan, making it a cost-effective solution for long-term use. Additionally, the circuit board is designed for easy integration into existing electronic systems, streamlining the production process and reducing time-to-market for new products.In addition to its high-quality construction, the Surface Mount Circuit Board is also backed by [Company Name]'s industry-leading technical support and customer service. With a team of experienced engineers and technicians, [Company Name] is committed to providing expert guidance and assistance to help customers integrate the circuit board into their applications seamlessly."We understand that our customers have unique requirements and challenges when it comes to their electronic projects," [Spokesperson] added. "That's why we offer personalized support and consultation to ensure that our Surface Mount Circuit Board meets and exceeds their expectations."With the introduction of the Surface Mount Circuit Board, [Company Name] continues to solidify its position as a trusted partner for electronic component solutions. The company's extensive product portfolio, combined with its dedication to innovation and customer satisfaction, has established [Company Name] as a leading force in the electronics industry.For more information about [Company Name] and its Surface Mount Circuit Board, please visit [Company Website] or contact [Contact Person] at [Contact Information].About [Company Name]:[Company Name] is a [City, State]-based company that specializes in providing high-quality electronic components and solutions to customers worldwide. With a focus on innovation and customer satisfaction, [Company Name] has become a trusted partner for businesses seeking reliable and efficient electronic solutions for their applications.###

High-Quality Small Batch PCB Assembly Services for Your Electronics Manufacturing Needs

Small Batch Pcb Assembly has become a key service offered by {} to meet the demands of today’s electronic manufacturing industry. As a leading provider of advanced electronics and PCB assembly services, {} has been at the forefront of delivering high-quality, reliable, and cost-effective solutions to support the growth and innovation of businesses across various sectors.With the increasing complexity and miniaturization of electronic components, companies are constantly seeking reliable and efficient PCB assembly services to meet their production needs. Small batch PCB assembly has emerged as a crucial requirement for businesses looking to develop prototypes, test new designs, or produce limited quantities of electronic devices. Recognizing this demand, {} has dedicated significant resources and expertise to streamline its small batch PCB assembly services to provide clients with the agility and flexibility they need to bring their concepts to life.In an interview with the company’s CEO, he stated, “At {}, we understand the challenges that our clients face when it comes to small batch PCB assembly. This is why we have invested in state-of-the-art manufacturing technologies and a highly skilled team to ensure that we can deliver high-quality, low-volume PCB assembly services with quick turnarounds. Our goal is to empower our clients to innovate and iterate their designs without the constraints of large-scale production requirements.”{}’s small batch PCB assembly services are designed to cater to a wide range of industries, including aerospace, automotive, medical devices, consumer electronics, and more. The company’s advanced assembly capabilities and strict quality control processes ensure that each assembled PCB meets the highest standards for performance, reliability, and durability.The small batch PCB assembly process at {} begins with a comprehensive review of the client’s design and requirements. The company’s team of experienced engineers works closely with the client to optimize the design for manufacturability and identify any potential issues that may arise during assembly. Once the design is finalized, {} leverages its advanced equipment and software to fabricate the PCBs and assemble the components with precision and efficiency.One of the key differentiators of {}’s small batch PCB assembly services is its commitment to quality and traceability. The company adheres to stringent quality standards throughout the assembly process, and each assembly undergoes rigorous testing and inspection to ensure that it meets the client’s specifications. Additionally, {} maintains detailed records of the assembly process, component sourcing, and testing results, providing clients with full traceability and transparency.In addition to its small batch PCB assembly services, {} also offers a range of value-added solutions to support its clients’ electronic manufacturing needs. These include design for manufacturability (DFM) reviews, component sourcing and procurement, prototyping, and full turnkey assembly services. With its comprehensive capabilities and commitment to customer satisfaction, {} has solidified its position as a trusted partner for businesses seeking reliable and high-quality PCB assembly solutions.As the demand for smaller, more advanced electronic devices continues to rise, the need for efficient and reliable small batch PCB assembly services will only become more critical. With its focus on innovation, quality, and customer-centric approach, {} is well-positioned to meet the evolving needs of the electronic manufacturing industry and empower businesses to bring their ideas to market with confidence.With a proven track record of delivering exceptional results and a strong commitment to continuous improvement, {} is set to remain a leader in providing small batch PCB assembly services that drive innovation and success for its clients across various industries.

Understanding the Key Benefits of Electronic PCB Assembly for Efficient Product Integration

Title: Electronic PCB Assembly Company, a Pioneer in Advanced Manufacturing Technologies, Sets New Industry StandardsSubtitle: Positioned at the Forefront of Revolutionary PCB Assembly Solutions, Company Remains Committed to Delivering Cutting-Edge Electronic Products[City, Date] - Electronic PCB Assembly Company, a renowned leader in the electronics manufacturing industry, has been setting new benchmarks with its advanced PCB assembly technologies. With a strong emphasis on innovation, quality, and customer satisfaction, the company has consistently positioned itself as a pioneer in delivering state-of-the-art electronic products to businesses across various sectors.Founded with the vision to revolutionize the electronics industry, Electronic PCB Assembly Company has become synonymous with cutting-edge manufacturing solutions and superior customer service. With a relentless drive for innovation and an unwavering commitment to excellence, the company has rapidly established itself as an industry leader.Electronic PCB Assembly Company specializes in providing comprehensive electronic manufacturing services (EMS), catering to businesses ranging from startups to multinational corporations. The company's expertise lies in the assembly of printed circuit boards (PCBs), which serve as the cornerstone for various electronic devices.Utilizing the latest technologies and adhering to stringent quality control measures, Electronic PCB Assembly Company delivers reliable and high-performing PCBs that meet the unique requirements of its diverse clientele. By employing advanced equipment, efficient processes, and highly skilled professionals, the company ensures the production of top-notch circuit boards that exhibit exceptional performance and durability.Moreover, Electronic PCB Assembly Company understands the importance of staying ahead in a dynamic and rapidly changing industry. The company invests extensively in research and development to stay at the forefront of emerging technologies. This commitment to innovation enables the company to offer innovative assembly solutions, designed to meet the challenges of tomorrow's electronic products.One of the key factors contributing to Electronic PCB Assembly Company's success is its customer-centric approach. The company strives to build long-term partnerships with its clients by understanding their specific needs and providing tailored solutions. By closely collaborating with customers throughout the development and production process, Electronic PCB Assembly Company ensures complete transparency and delivers products that meet and exceed expectations.The company's dedication to quality is evident through its adherence to industry-leading certifications and standards. Electronic PCB Assembly Company follows strict manufacturing protocols, including ISO 9001:2015 and IPC-A-610, to guarantee the highest level of quality assurance. These certifications illustrate the company's unwavering commitment to consistently deliver products that meet international quality benchmarks.Furthermore, Electronic PCB Assembly Company is deeply committed to environmental sustainability. The company actively promotes eco-friendly manufacturing practices and complies with global directives aimed at reducing electronic waste. By adopting environmentally conscious approaches, such as proper waste management and responsible disposal processes, Electronic PCB Assembly Company ensures the protection of the environment while contributing to a more sustainable future.In conclusion, Electronic PCB Assembly Company has emerged as a trailblazer in the field of advanced manufacturing technologies. With its innovative approaches, unparalleled expertise, and customer-centric values, the company has successfully set new industry standards. With a firm commitment to quality, innovation, and sustainability, Electronic PCB Assembly Company continues to spearhead the electronics manufacturing industry by delivering cutting-edge electronic products that meet the evolving demands of businesses worldwide.For media inquiries, please contact:[Name][Title][Company Name][Phone number][Email address]About Electronic PCB Assembly Company:Electronic PCB Assembly Company is a leading provider of electronic manufacturing services, specializing in the assembly of printed circuit boards. With a focus on innovation, quality, and customer satisfaction, the company delivers advanced PCB assembly solutions to businesses across diverse industries. Committed to remaining at the forefront of emerging technologies, Electronic PCB Assembly Company remains dedicated to providing cutting-edge electronic products and fostering long-term partnerships with its clients.

Top Tips for Choosing the Right PCBA for Your Needs

PCBA Manufacturer Leads the Industry with Cutting-Edge TechnologyIn the fast-paced world of electronics manufacturing, having a reliable and innovative printed circuit board assembly (PCBA) partner is crucial. This is why companies across various industries are turning to {Company Name} for their PCBA needs. With a proven track record for delivering high-quality solutions, {Company Name} is leading the industry with their cutting-edge technology and commitment to customer satisfaction.{Company Name} was established in 1998 with a vision to become a one-stop solution for all PCBA requirements. Over the years, the company has consistently invested in state-of-the-art technology and equipment, allowing them to stay ahead of the competition. Their dedication to research and development has enabled them to offer a wide range of services, including PCB layout, PCB fabrication, component sourcing, soldering, and testing.One of the key factors that set {Company Name} apart from their competitors is their emphasis on quality. They have obtained various certifications, including ISO 9001 and ISO 14001, demonstrating their commitment to the highest standards of manufacturing and environmental management. Additionally, they strictly adhere to international standards such as IPC-A-600 and IPC-A-610, ensuring that all their products meet the stringent requirements of their clients.Moreover, {Company Name} has also made significant strides in the implementation of advanced technologies in their manufacturing processes. They have adopted automated assembly lines and robotic machinery, which increases efficiency and reduces the margin of error. This level of automation not only accelerates production but also ensures that every PCB assembly is of the highest quality.Furthermore, {Company Name} has made substantial investments in research and development, particularly in the field of surface mount technology (SMT). Their SMT capabilities include advanced solder paste printing, high-speed pick and place machines, and high-precision reflow soldering, allowing them to handle complex PCB designs with utmost precision and accuracy.In addition to their technological prowess, {Company Name} takes pride in their customer-centric approach. They understand that each client has unique requirements, which is why they offer personalized solutions tailored to the specific needs of their customers. Moreover, their team of experienced engineers and technicians work closely with clients to provide comprehensive support and guidance throughout the entire manufacturing process.Furthermore, {Company Name} caters to a diverse range of industries, including automotive, aerospace, telecommunications, medical devices, consumer electronics, and more. Their ability to produce PCB assemblies that are compliant with the regulatory standards of different sectors has earned them a stellar reputation among their clients.Looking ahead, {Company Name} is poised to continue its growth and innovation in the PCBA industry. With the rise of Internet of Things (IoT), artificial intelligence, and other emerging technologies, the demand for high-quality PCB assemblies is expected to increase. {Company Name} is well-equipped to meet this demand by constantly evolving their capabilities and staying at the forefront of technological advancements.In conclusion, {Company Name} is a leading PCBA manufacturer that has set itself apart through its cutting-edge technology, commitment to quality, and customer-centric approach. With a strong foundation built on innovation and excellence, {Company Name} is well-positioned to meet the evolving needs of the electronics manufacturing industry for years to come.

Top 5 Tips for Efficiently Assembling a Product

Assembly Of Product, a leading company in the field of manufacturing and assembly services, has recently announced the launch of its new state-of-the-art facility. This facility is specifically designed to cater to the growing demands of the assembly of a wide range of products, from consumer electronics to industrial machinery.With over 20 years of experience in the industry, Assembly Of Product has established itself as a trusted partner for businesses looking for high-quality, cost-effective assembly solutions. The company's commitment to excellence and innovation has made it a preferred choice for clients across various industries.The new facility, located in a strategic location, is equipped with advanced machinery and technology to streamline the assembly process and ensure precision and efficiency. With a focus on automation and robotics, Assembly Of Product aims to enhance productivity and reduce production lead times for its clients.In addition to its cutting-edge infrastructure, the facility is also designed to meet the highest standards of safety and environmental regulations. Assembly Of Product understands the importance of sustainability and is dedicated to minimizing its environmental impact through responsible manufacturing practices.The company's skilled and experienced workforce is another key asset that sets it apart in the industry. With a team of highly trained technicians and engineers, Assembly Of Product has the expertise to handle complex assembly projects with precision and attention to detail."We are excited to announce the opening of our new facility, which marks a significant milestone in our journey," said [CEO's Name], CEO of Assembly Of Product. "This expansion is a testament to our commitment to meeting the evolving needs of our clients and delivering exceptional assembly services that exceed their expectations."Assembly Of Product's dedication to customer satisfaction and continuous improvement has earned it a strong reputation in the market. The company has built long-lasting partnerships with clients who rely on its expertise to bring their products to market with speed and efficiency.The new facility is expected to further strengthen Assembly Of Product's position as a leader in the assembly services industry. With increased capacity and capabilities, the company is well-equipped to take on larger and more complex projects, catering to the diverse needs of its expanding client base.In line with its goal to be a one-stop solution for assembly needs, Assembly Of Product offers a comprehensive range of services, including prototype assembly, production assembly, testing, and packaging. The company's flexibility and agility allow it to tailor its services to meet the specific requirements of each client, regardless of the size or scope of the project.As Assembly Of Product continues to grow and evolve, it remains committed to upholding its values of integrity, innovation, and excellence. The company's dedication to quality and customer satisfaction positions it as a reliable partner for businesses seeking top-notch assembly services.With the opening of its new facility, Assembly Of Product is poised to embark on an exciting new chapter of growth and success. The company's unwavering commitment to pushing the boundaries of assembly technology and delivering superior solutions sets it apart as a leader in its field.

Top Blue Chip ETFs to Consider for Your Investment Portfolio

Blue Chip ETFs have gained popularity among investors seeking exposure to large, stable companies with strong financial performance. These ETFs offer a way to invest in a diversified portfolio of blue-chip stocks, providing a convenient and cost-effective way to gain exposure to these well-established companies.Blue Chip ETFs typically include companies that have a long history of consistent earnings, a strong balance sheet, and a solid reputation in their respective industries. These companies are often leaders in their market segments, making them less susceptible to market volatility and economic downturns.One company that offers a Blue Chip ETF is [Company Name]. [Company Name] is a leading provider of exchange-traded funds, with a focus on delivering innovative investment solutions to investors. The company prides itself on offering a wide range of ETFs across various asset classes, including equities, fixed income, and commodities.The [Company Name] Blue Chip ETF is designed to track the performance of a market index that is composed of blue-chip stocks. This ETF provides investors with exposure to some of the largest and most well-known companies in the market, offering the potential for long-term growth and stability.The [Company Name] Blue Chip ETF is ideal for investors who are looking for a way to gain exposure to a diversified portfolio of blue-chip stocks without having to select and manage individual stocks themselves. By investing in this ETF, investors can benefit from the expertise of professional fund managers who are responsible for selecting and managing the portfolio of blue-chip stocks.One of the key advantages of investing in Blue Chip ETFs is the diversification they offer. By holding a basket of blue-chip stocks, investors can spread their risk across multiple companies and industries, reducing the impact of any single company's performance on their overall investment.In addition, Blue Chip ETFs can provide investors with a convenient and cost-effective way to access a diversified portfolio of blue-chip stocks. These ETFs can be bought and sold on major stock exchanges like regular stocks, offering liquidity and flexibility to investors.Furthermore, Blue Chip ETFs are known for their relatively low expenses compared to actively managed funds. With lower management fees and operating costs, Blue Chip ETFs can be a cost-effective option for investors looking to gain exposure to blue-chip stocks.The [Company Name] Blue Chip ETF also offers the potential for dividend income. Many blue-chip companies are known for paying regular dividends, and by holding a portfolio of these companies through the ETF, investors can potentially benefit from a steady stream of dividend income.Overall, Blue Chip ETFs can be an attractive option for investors seeking exposure to large, stable companies with a proven track record of performance. With their diversification, cost-effectiveness, and potential for long-term growth and income, Blue Chip ETFs can be a valuable addition to a well-diversified investment portfolio.In conclusion, Blue Chip ETFs offer investors a convenient and cost-effective way to gain exposure to a diversified portfolio of blue-chip stocks. The [Company Name] Blue Chip ETF provides investors with the opportunity to invest in some of the largest and most well-established companies in the market, offering the potential for long-term growth and stability. With their diversification, cost-effectiveness, and potential for dividend income, Blue Chip ETFs can be a valuable addition to a well-diversified investment portfolio.

Key Considerations for Implementing Surface Mounting Devices in Electronic Manufacturing

Title: Revolutionizing the Electronics Industry: Surface Mounting Devices Take Center StageIntroduction:In the fast-paced world of technology, Surface Mounting Devices (SMDs) have emerged as a game-changing innovation, revolutionizing the way electronic components are assembled onto circuit boards. With the ability to enhance efficiency, reduce costs, and improve product performance, SMDs have become the go-to choice for manufacturers looking to stay ahead in the competitive electronics industry. This article explores the rise of SMDs and their impact on the sector.------Body:I. What are Surface Mounting Devices (SMDs)?Surface Mounting Devices, commonly referred to as SMDs, are miniature electronic components specifically designed to be mounted directly onto the surface of a circuit board. Unlike the traditional through-hole mounting method, which involves drilling holes into the board, SMDs are soldered onto the board using specialized equipment. This innovative technology eliminates the need for bulky wires, making SMDs ideal for compact and lightweight electronic devices.II. Advantages of SMDs:1. Size: SMDs are much smaller compared to through-hole components, allowing for miniaturization of electronic products. This reduction in size enables the creation of sleek and slim devices, catering to the growing demand for portable and wearable technology.2. Efficiency: Due to their smaller size, SMDs offer improved electrical performance. The short electrical paths between components reduce parasitic capacitance and inductance, resulting in faster signal transmission, lower power consumption, and enhanced overall efficiency.3. Cost-effectiveness: SMDs enable automated assembly processes, reducing labor costs and increasing production capacity. The efficiency of the assembly process allows for high-volume production, resulting in economies of scale and lower manufacturing costs per unit.4. Reliability: SMDs provide higher reliability due to their capability to withstand mechanical stresses, such as vibration and impact, better than traditional through-hole components. The direct attachment to the circuit board also reduces the risk of accidental disconnections.III. Market Impact of SMD Technology:1. Industry Growth: The growing popularity of SMDs has fueled the expansion of the global electronics market. With the proliferation of smartphones, wearable devices, and Internet of Things (IoT) applications, the demand for SMDs has skyrocketed. The market is expected to reach a valuation of USD X.XX billion by the end of 20XX.2. Increased Productivity: SMDs have significantly enhanced the productivity of electronics manufacturers. The automated assembly processes for SMDs provide faster production cycles, shorter time to market, and improved overall product output. This increased efficiency has directly contributed to the growth and success of many companies in the electronics sector.3. Supply Chain Optimization: The adoption of SMDs has necessitated changes throughout the electronics supply chain. Companies have shifted their focus towards sourcing materials and equipment specifically required for SMD assembly. This has led to advancements in infrastructure, material handling, packaging, and logistics, resulting in a more efficient and streamlined supply chain.IV. Leading Companies in the SMD Industry:Several key players in the electronics industry have emerged as frontrunners in the development and production of SMDs. These companies continue to innovate and refine SMD technology, maintaining their competitive edge in the market. Notable names include a global electronic components manufacturer, widely recognized for its state-of-the-art SMD solutions, as well as other industry giants who have embraced SMD technology to achieve uninterrupted success.V. Future Prospects and Challenges:As technology evolves, SMDs are expected to play a crucial role in various emerging sectors. From automotive electronics to renewable energy systems, SMDs are poised to lead the way, enabling sleeker designs, improved performance, and increased functionality. However, the ongoing miniaturization of devices presents challenges such as handling smaller components, managing thermal issues, and ensuring reliability in extreme conditions. Companies must continuously innovate to overcome these hurdles and stay at the forefront of SMD technology advancements.Conclusion:Surface Mounting Devices have become a cornerstone of the electronics industry, offering numerous advantages in terms of size, efficiency, cost-effectiveness, and reliability. With their widespread usage in various electronic products, SMDs have revolutionized the way components are mounted onto circuit boards, driving industry growth and improving efficiency throughout the supply chain. As technology continues to advance, SMDs are expected to further shape the future of electronics, catering to the demand for smaller, faster, and more reliable devices.