How to Improve the Efficiency of Your Assembly Line Process

By:Admin

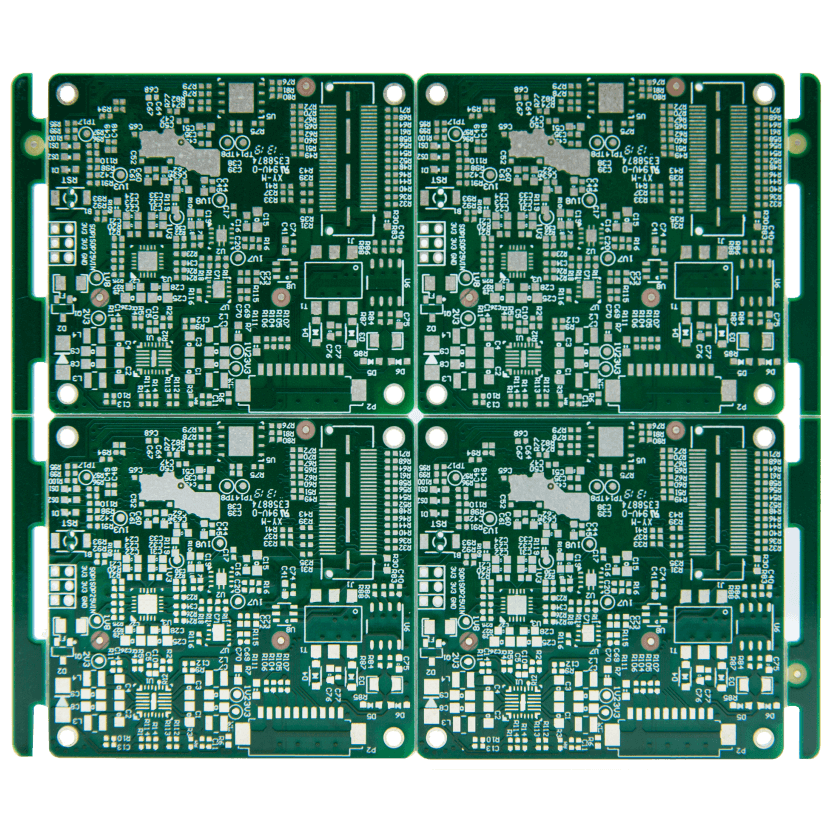

The new facility boasts advanced SMT assembly capabilities, including high-speed pick-and-place machines, cutting-edge stencil printers, and top-of-the-line reflow ovens. This investment in the latest technology will allow SMT Assembly to further enhance their production efficiency and deliver high-quality electronic assemblies with quick turnaround times.

In addition to the technological advancements, the new facility is strategically located to better serve their customers in the (specific) region. By being closer to their clients, SMT Assembly aims to strengthen their partnerships and provide more personalized support.

With a focus on quality and precision, SMT Assembly has built a reputation for delivering reliable and cost-effective electronic manufacturing solutions. Their team of highly skilled engineers and technicians are dedicated to ensuring that every product meets the highest standards of excellence. The company's commitment to quality is highlighted by their adherence to rigorous quality control processes and their compliance with industry standards and regulations.

SMT Assembly specializes in providing electronic manufacturing services for a wide range of industries, including aerospace, automotive, medical, and consumer electronics. Their comprehensive capabilities include PCB assembly, box build assembly, testing, and fulfillment services. With a customer-centric approach, they work closely with their clients to understand their unique requirements and provide tailored solutions to meet their specific needs.

The company's dedication to continuous improvement is reflected in their certification to ISO 9001 and ISO 13485 standards. These certifications demonstrate their commitment to quality management and their ability to consistently meet customer and regulatory requirements.

In addition to their commitment to quality, SMT Assembly is also dedicated to environmental sustainability. They have implemented eco-friendly practices in their manufacturing processes and strive to minimize their impact on the environment. By incorporating lead-free soldering, energy-efficient equipment, and waste reduction initiatives, they are committed to being responsible corporate citizens.

The launch of the new facility is a significant milestone for SMT Assembly, representing their continued growth and commitment to excellence. With their advanced capabilities, strategic location, and customer-centric approach, they are well-positioned to continue serving the evolving needs of their clients and further solidify their position as a leader in the electronic manufacturing industry.

As SMT Assembly expands their operations and invests in cutting-edge technology, they are well-equipped to address the growing demand for high-quality electronic assemblies. With a focus on innovation, quality, and customer satisfaction, they are poised for continued success in the dynamic and competitive electronic manufacturing landscape.

Company News & Blog

Innovative Rigid Flexible Technology: The Future of Flexible Electronics

Rigid Flexible, a leading provider of advanced materials and engineered solutions, has announced the launch of their latest product line designed to meet the growing demand for flexible materials in various industries. With a focus on innovation and cutting-edge technology, Rigid Flexible has developed a range of flexible materials that offer superior performance and durability.With a strong commitment to delivering high-quality products, Rigid Flexible has positioned itself as a trusted partner for companies seeking reliable and efficient solutions for their flexible material needs. The company has a proven track record of successfully delivering innovative products that meet the specific requirements of their clients, and their latest product line is no exception.The new product line from Rigid Flexible offers a wide range of flexible materials that are suitable for a variety of applications, including automotive, aerospace, electronics, and medical devices. These materials are designed to provide a unique combination of flexibility and strength, allowing for greater versatility and performance in a wide range of applications.In addition to their exceptional performance, Rigid Flexible's flexible materials are also designed to meet the highest standards of quality and safety. The company has strict quality control processes in place to ensure that all of their products meet or exceed industry standards, providing peace of mind for their customers.One of the key advantages of Rigid Flexible's flexible materials is their ability to be customized to meet the specific needs of each client. The company's team of experienced engineers and materials experts work closely with clients to develop tailored solutions that address their unique requirements, ensuring maximum performance and reliability.Rigid Flexible also offers a range of value-added services, including material testing, design assistance, and technical support, to ensure that their clients receive the highest level of service and support throughout the entire product development process.The launch of Rigid Flexible's new product line is a testament to the company's ongoing commitment to innovation and excellence. With a focus on delivering cutting-edge solutions that meet the evolving needs of their clients, Rigid Flexible is well-positioned to continue leading the market in flexible materials and engineered solutions.In conclusion, Rigid Flexible's new product line represents a significant milestone for the company and the industries they serve. With a focus on innovation, quality, and customer satisfaction, Rigid Flexible is poised to continue their success as a leading provider of flexible materials and engineered solutions.

Mastering the Art of Effective PCB Layouting Techniques for Seamless Electronics Integration

PCB Layouting: Revolutionizing Electronic Components ManufacturingThe global electronics industry has witnessed a significant transformation over the last few decades, with an increased demand for innovative and high-performance electronic gadgets. The increasing demand has generated an unprecedented competitive environment in the industry, emphasizing more on cost-effectiveness, efficient performance, and advanced technology.Electronic components manufacturing involves several stages that contribute to the final product's cleanliness, reliability, and performance. One of the most crucial stages in electronic components manufacturing is the Printed Circuit Board (PCB) layout.A PCB layout is the designing process of an electronic circuit board that integrates different electronic components and connects them through copper traces. An efficient PCB layout plays a vital role in determining the product's performance, reliability, and longevity.With the technological advancements in the field, PCB layouting has undergone a significant transformation, enhancing the process's speed, accuracy, and efficiency. With the help of advanced tools and software, PCB layouting has become relatively quicker and more reliable than ever before.One such company that has made a recognizable imprint in the electronic components manufacturing industry is the (remove brand name). Founded in (year of establishment), the company has been offering top-notch electronic components and solutions to customers worldwide.The company is known for its innovative and efficient solutions, delivering quality products and services to customers of diverse sectors, including automotive, aerospace, communication, medical, and industrial sectors.The company has a team of experienced and highly skilled professionals who work tirelessly to provide solutions that meet the growing needs of the electronics market. In addition, the company has integrated advanced technologies in their manufacturing processes to drive efficiency, reduce lead time, and ensure cost-effectiveness.The company's PCB layouting services are second to none, offering customized solutions to customers to meet their specific needs. With the help of sophisticated software, the company ensures precise placement and routing of the components, ensuring minimal signal interference and optimized signal efficiency.One of the company's key strengths is its adherence to industry standards in manufacturing processes. The company recognizes the importance of adhering to set standards in ensuring product quality and reliability. As a result, the company has implemented a robust Quality Management System that ensures consistent quality standards that meet the requirements of customers worldwide.In addition, the company adheres to environmentally conscious manufacturing processes, ensuring sustainability in their manufacturing activities. The company emphasizes the use of eco-friendly materials and processes in delivering solutions that are environmentally safe and sustainable.The company's commitment to innovation, efficiency, and quality has earned them well-deserved recognition in the electronics industry. The company has received several awards and certifications, including the ISO 9001 certification, showing their commitment to meeting quality management standards.In conclusion, PCB layouting is a crucial stage in electronic components manufacturing that determines the product's performance and reliability. The process requires precision, accuracy, and efficiency, and specialized companies such as (remove brand name) have revolutionized the process. Through their innovative solutions, adherence to industry standards, and commitment to sustainability, the company continues to offer top-notch PCB layouting services to customers worldwide, contributing to the electronics industry's growth and development.

Top Trends in Flexible Printed Circuit Boards You Need to Know

Flex PCBs: The Next Generation of Printed Circuit BoardsIn the world of electronics, the demand for smaller, more flexible, and more durable components is constantly increasing. With the rise of wearables, smart devices, and IoT (Internet of Things) products, traditional rigid printed circuit boards (PCBs) are no longer sufficient to meet the needs of modern technology. This is where Flex PCBs come into play.Flex PCBs, also known as flexible printed circuit boards, are a revolutionary advancement in PCB technology. They are designed to be more versatile and adaptable than their rigid counterparts, allowing for a greater degree of flexibility and bending without compromising performance or reliability. This makes them ideal for applications where space is limited, and where a traditional rigid PCB would be impractical.One company at the forefront of this cutting-edge technology is {}. Founded in {}, the company has quickly established itself as a leader in the design and manufacturing of Flex PCBs. With a strong focus on innovation and quality, {} has become a trusted partner for industries such as consumer electronics, automotive, medical devices, and more.The secret behind the success of {} lies in their commitment to research and development. They have invested heavily in state-of-the-art manufacturing equipment and processes, allowing them to produce Flex PCBs that not only meet but exceed industry standards. With a dedicated team of engineers and technicians, {} is able to provide custom solutions to meet the specific needs of their clients, ensuring that their products are tailored to each unique application.One of the key advantages of Flex PCBs is their ability to conform to the shape of the product they are integrated into. This means that they can be bent, folded, or twisted without compromising their functionality, making them the perfect choice for applications where space is at a premium. Additionally, the flexible nature of these PCBs makes them more resistant to shock and vibration, making them ideal for use in rugged environments.Another advantage of Flex PCBs is their lightweight and compact nature. This makes them ideal for use in portable devices, as well as in applications where weight and space are critical considerations. The reduced weight and size of Flex PCBs also contribute to lower production costs, as they require fewer materials and less complex assembly processes.In addition to their physical characteristics, Flex PCBs also offer improved signal integrity and reduced electromagnetic interference compared to traditional rigid PCBs. This makes them ideal for high-speed and high-frequency applications, where signal integrity is critical to the overall performance of the product.With the increasing demand for smaller, more flexible, and more durable electronic components, the adoption of Flex PCBs is expected to continue to grow. As technology continues to evolve, the need for innovative solutions such as Flex PCBs will only become more pressing. With their expertise and commitment to excellence, {} is well-positioned to lead the way in this exciting new frontier of PCB technology.In conclusion, Flex PCBs represent the next generation of printed circuit boards, providing a level of flexibility, durability, and performance that was previously unattainable with traditional rigid PCBs. With companies like {} leading the way, the future of electronics looks brighter than ever.

Cutting-Edge Single PCB Technology Revolutionizes Electronic Manufacturing Process

In the world of electronics, printed circuit boards (PCBs) have become the go-to solution for creating complex and intricate circuits. However, the traditional process of designing and manufacturing PCBs involves multiple steps, which can take up a significant amount of time and resources. However, that is all changing with the emergence of Single PCB, a revolutionary technology that promises to reduce the complexity and cost of PCB design and manufacturing.Single PCB is a brand new technology that allows for the creation of PCBs in a single step. This means that designers can create entire circuits using just a single board, which saves time and resources. Additionally, this technology eliminates the need for multiple components, reducing the overall cost of PCB production.At the forefront of this technology is a company, whose innovative single PCB technology has the potential to revolutionize the electronics industry. With over a decade of experience in PCB design and manufacturing, this company has developed a comprehensive range of solutions that has set it apart from its competitors.Headquartered in [city, country], the company prides itself on being a leading provider of PCB related services and solutions. With a team of highly skilled and experienced professionals, the company has built a reputation for excellence in the industry.The company's single PCB technology is the result of years of research and development. The technology has been specifically designed to simplify the process of PCB design and production, making it more accessible to a wider range of users.One of the biggest advantages of the single PCB technology is its ability to reduce the complexity of the design process. With traditional PCB manufacturing, designers had to create multiple boards and then connect them using a variety of connectors and wires. This process was time-consuming, and there was always the risk of errors occurring during assembly. However, with the single PCB technology, designers can create an entire circuit on a single board, eliminating the need for additional components and saving time and money.Another important benefit of the single PCB technology is the reduction in the overall cost of PCB production. With traditional PCB manufacturing, there were multiple steps involved, including designing the boards, assembling the components, and testing the finished product. However, with single PCB technology, the entire process can be completed in a single step, reducing the overall cost of production.The single PCB technology has also been designed with flexibility in mind. This means that designers can create circuits of varying complexity, adapting the technology to suit their specific needs. Additionally, the technology can be used to create a wide range of products, from simple electronic toys to complex medical equipment.As the world becomes more reliant on technology, the demand for innovative and efficient PCB manufacturing solutions is only going to increase. Single PCB technology is poised to meet this demand head-on, offering a simple and cost-effective solution for creating cutting-edge electronic products.In conclusion, the emergence of Single PCB technology is a game-changer for the electronics industry. With its simplified design process, reduced manufacturing costs, and flexibility, this technology has the potential to reshape the way we design and manufacture electronic products. The company behind this technology is poised to lead the way in the single PCB market, offering customers a comprehensive range of solutions that are designed to meet their specific needs and requirements.

Advanced Circuit Card Assemblies for Efficient Electronic Devices

Circuit Card Assemblies, a leading manufacturer of electronic components, has recently announced the launch of their latest line of advanced circuit card assemblies. With a focus on innovation and cutting-edge technology, the company has been at the forefront of the electronics industry for over two decades.Established in 1998, Circuit Card Assemblies has built a reputation for excellence in the design, manufacturing, and assembly of high-quality electronic components. Their state-of-the-art facilities and skilled team of engineers have enabled them to consistently deliver superior products to their clients across various industries, including aerospace, defense, telecommunications, and medical devices.The newly released circuit card assemblies boast a range of advanced features, including high-speed data transmission, increased power efficiency, and enhanced durability. With the ever-growing demand for smaller, more efficient electronic devices, these new assemblies are perfectly positioned to meet the needs of the rapidly evolving technology landscape.In a statement, the company's CEO expressed their excitement about the launch of the new circuit card assemblies, stating that "We are thrilled to introduce our latest line of advanced electronic components. Our team has worked tirelessly to push the boundaries of technology and engineering, and we are confident that these new assemblies will continue to set the standard for excellence in the industry."The company's commitment to innovation and quality is further evident in their rigorous testing and validation processes. Each circuit card assembly undergoes extensive testing to ensure that it meets the highest standards for performance and reliability. This attention to detail is what has earned Circuit Card Assemblies the trust and loyalty of their clients over the years.Furthermore, Circuit Card Assemblies is dedicated to sustainability and environmental responsibility. They have implemented eco-friendly practices throughout their manufacturing processes, aiming to reduce their carbon footprint and minimize waste. This commitment to sustainability aligns with the increasing focus on environmentally friendly practices in the electronics industry.With their new line of circuit card assemblies, Circuit Card Assemblies aims to continue their tradition of excellence and innovation in the electronics industry. These advanced electronic components are set to play a crucial role in powering the next generation of electronic devices and technologies.As the demand for smaller, more efficient electronic components continues to grow, Circuit Card Assemblies remains at the forefront of the industry, offering innovative solutions to meet the evolving needs of their clients. With their dedication to quality, sustainability, and advanced technology, Circuit Card Assemblies is well-positioned to maintain their status as a leader in electronic component manufacturing for years to come.In conclusion, Circuit Card Assemblies has once again demonstrated their commitment to excellence with the launch of their latest line of advanced circuit card assemblies. Their dedication to innovation, quality, and sustainability sets them apart as a leader in the electronics industry. As technology continues to advance at a rapid pace, Circuit Card Assemblies remains a trusted partner for businesses seeking high-quality electronic components to power their products.

Top Access Control System Features for Improved Security

Access Control System (ACS) has become an essential part of modern security measures for companies and organizations. It allows for the control of who is able to enter or exit a specific area at a given time, providing enhanced security and peace of mind. One company that has been at the forefront of providing reliable and efficient access control solutions is {}. With a strong focus on innovation and customer satisfaction, {} has established itself as a leader in the industry.{} was founded in 2005, with the aim of revolutionizing access control systems and providing customized solutions to meet the specific needs of each client. Over the years, the company has developed a wide range of access control products that are designed to ensure the safety and security of businesses, institutions, and individuals. From traditional keycard access systems to more advanced biometric recognition technology, {} offers a comprehensive suite of options to cater to the diverse needs of its customers.One of the key products offered by {} is the Access Control System, which has gained widespread acclaim for its reliability and effectiveness. The system is designed to provide seamless access control for businesses, helping to prevent unauthorized entry and enhancing overall security. With features such as time-based access control, activity tracking, and remote access management, the Access Control System from {} has proven to be a valuable asset for companies looking to protect their assets and personnel.In addition to its innovative products, {} is also known for its exceptional customer service and support. The company employs a team of highly trained professionals who are dedicated to assisting clients in identifying the most suitable access control solutions for their specific requirements. From initial consultation to system installation and ongoing maintenance, {} is committed to ensuring that its customers receive the highest level of support and satisfaction.Alongside its dedication to quality and customer satisfaction, {} is also deeply committed to innovation and continuous improvement. The company invests heavily in research and development, constantly striving to enhance its products with the latest advancements in technology. This proactive approach has allowed {} to stay ahead of the curve and deliver cutting-edge access control solutions that meet the evolving needs of the security industry.As the demand for robust access control systems continues to grow, {} remains a trusted partner for companies and organizations seeking reliable and effective security solutions. The company's commitment to excellence, combined with its focus on innovation, makes it a top choice for businesses looking to enhance their security measures. With a track record of success and a strong reputation in the industry, {} is poised to continue its leadership in the access control market for years to come.In conclusion, the Access Control System from {} represents the pinnacle of security and access control technology. With a strong emphasis on innovation, customer satisfaction, and continuous improvement, {} has established itself as a leader in the industry. Businesses and organizations looking to enhance their security measures can trust {} to provide reliable, efficient, and customized access control solutions that meet their specific needs.For more information about the Access Control System from {} and the company's other products and services, please visit the official website or contact a representative for a consultation. With {} as a trusted partner, businesses can rest assured that their security needs are in good hands.

Improve Your PCBA Testing with These Tips and Best Practices

PCBA Test Revolutionizes Quality Assurance for Electronics Manufacturing ProcessesIn today's increasingly interconnected world, the demand for electronic devices continues to rise. From smartphones to smart appliances, electronic components have become an essential part of everyday life. As a result, manufacturers are under immense pressure to produce high-quality electronic products at a rapid pace. To meet these demands, {Company Name} has developed a cutting-edge PCBA test solution that revolutionizes quality assurance for electronics manufacturing processes.Founded in 2005, {Company Name} is a global leader in the electronic manufacturing services industry. With state-of-the-art facilities and a team of experienced engineers, the company is dedicated to providing innovative solutions for the production of high-quality electronic products. As part of its commitment to excellence, {Company Name} has developed a comprehensive PCBA test solution that ensures the reliability and performance of electronic components.The PCBA test solution offered by {Company Name} is designed to streamline the quality assurance process for electronics manufacturing. By incorporating advanced testing technologies and rigorous quality control measures, the solution is capable of detecting defects and abnormalities in the production of printed circuit board assemblies (PCBAs). This allows manufacturers to identify and address potential issues early in the production process, minimizing the risk of defective products reaching the market.One of the key features of {Company Name}'s PCBA test solution is its ability to conduct comprehensive testing of PCBAs. Utilizing a combination of functional testing, in-circuit testing, and boundary scan testing, the solution is able to evaluate the electrical functionality and integrity of electronic components. This level of thorough testing ensures that PCBAs meet the highest performance standards and comply with industry regulations.In addition to its advanced testing capabilities, {Company Name}'s PCBA test solution also offers real-time data analysis and reporting. This allows manufacturers to gain valuable insights into the performance of their production processes and rapidly address any issues that may arise. By leveraging data-driven decision-making, manufacturers can optimize their production processes and improve overall efficiency.Furthermore, {Company Name}'s PCBA test solution is scalable and adaptable to the unique needs of each customer. Whether it's small-scale production or high-volume manufacturing, the solution can be tailored to accommodate varying production requirements. This flexibility makes it an ideal choice for a wide range of electronic manufacturing applications.The impact of {Company Name}'s PCBA test solution on the electronics manufacturing industry is significant. With its ability to enhance quality assurance and efficiency, the solution is poised to drive innovation and improvement in the production of electronic products. By reducing the risk of defects and ensuring the reliability of electronic components, manufacturers can enhance their competitiveness in the market and deliver superior products to consumers.As the demand for electronic products continues to grow, the need for robust quality assurance solutions has never been more critical. {Company Name}'s PCBA test solution represents a significant advancement in the field of electronics manufacturing, providing manufacturers with a powerful tool to ensure the quality and performance of their products. With its advanced testing capabilities, real-time data analysis, and scalability, the solution is set to revolutionize quality assurance processes across the industry.

Top Tips for Choosing the Best SMD Board for Your Project

SMD Board Technology: Revolutionizing Electronic CircuitsIn the ever-evolving world of electronics, the demand for smaller, more efficient, and high-performance circuit boards has never been greater. Electronic devices are becoming more compact and powerful, requiring circuit boards that can accommodate these technological advancements. This is where SMD Board comes into play. The company has been at the forefront of revolutionizing electronic circuits with its innovative SMD (Surface Mount Device) technology. SMD Board, headquartered in [location], has been a leader in the electronic manufacturing industry since its establishment in [year]. The company specializes in the design and production of high-quality SMD boards that are used in a wide range of electronic applications. With a strong focus on research and development, SMD Board has continuously pushed the boundaries of what is possible in electronic circuit design. SMD boards, also known as surface mount technology (SMT) boards, have become the preferred choice for electronic manufacturers due to their numerous advantages over traditional through-hole technology. SMD boards are smaller, lighter, and more reliable, making them ideal for modern electronic devices. The SMD technology allows for components to be mounted directly onto the surface of the board, eliminating the need for holes and leads, thus reducing the overall size of the board. This results in electronic devices that are not only smaller but also more efficient and cost-effective.One of the key features of SMD Board's technology is its ability to accommodate a high density of components on a single board. This high component density allows for more complex and powerful electronic circuits to be designed and manufactured, meeting the demands of today's cutting-edge electronic devices. In addition, SMD Board's advanced manufacturing processes ensure the reliability and durability of its SMD boards, making them suitable for a wide range of applications, including consumer electronics, automotive systems, medical devices, and telecommunications equipment.The company's commitment to quality and innovation has positioned SMD Board as a trusted partner for electronic manufacturers around the world. By offering customizable solutions and unparalleled technical support, SMD Board has built a reputation for delivering exceptional SMD boards that meet the specific needs of its customers. The company's team of experienced engineers and technicians work closely with clients to develop bespoke SMD board designs that optimize performance and efficiency.SMD Board's dedication to sustainability and eco-friendly manufacturing practices sets it apart in the electronic manufacturing industry. The company adheres to strict environmental standards and continuously seeks ways to minimize its carbon footprint. This includes the use of lead-free solder and other environmentally friendly materials in its SMD board manufacturing process. SMD Board's commitment to sustainability not only benefits the environment but also ensures that its customers receive the highest quality and ethically produced SMD boards.Looking ahead, SMD Board is poised for continued growth and innovation in the electronic manufacturing industry. The company remains committed to staying at the forefront of SMD technology, leveraging its expertise and resources to develop cutting-edge solutions that meet the evolving needs of the electronics market. With a focus on quality, reliability, and customer satisfaction, SMD Board is well-positioned to be a driving force in shaping the future of electronic circuits and devices.In conclusion, SMD Board's SMD technology has redefined electronic circuit design and manufacturing, offering smaller, more efficient, and high-performance SMD boards that are setting new industry standards. With a dedication to innovation, sustainability, and customer satisfaction, SMD Board continues to be a trusted leader in the electronic manufacturing industry, providing tailor-made solutions for the electronic devices of tomorrow.

Expert Tips for High Volume PCB Assembly

high volume PCB assembly is one of the most critical and complex operations in the electronics manufacturing industry. It involves the assembly of a large number of printed circuit boards (PCBs) with various electronic components such as resistors, capacitors, diodes, and integrated circuits. This process requires precision, efficiency, and advanced technologies to ensure the highest quality and reliability of the final product. One company that has excelled in high volume PCB assembly is {Company Name}.{Company Name} is a leading provider of electronic manufacturing services (EMS) with a strong focus on high volume PCB assembly. With state-of-the-art facilities and advanced equipment, the company has the capability to handle large-scale production of PCBs for a wide range of applications, including consumer electronics, automotive, industrial equipment, medical devices, and more.The high volume PCB assembly process at {Company Name} begins with the careful selection of high-quality materials and components to ensure the reliability and performance of the final product. The company works closely with its suppliers to source the best materials and components that meet the specific requirements of each customer's project.Once the materials and components are procured, the PCB assembly process begins with the placement of the components on the PCBs. {Company Name} utilizes advanced pick-and-place machines and automated assembly lines to achieve high precision and efficiency in the component placement process. These machines are capable of placing thousands of components per hour, ensuring fast and accurate assembly of the PCBs.After the components are placed, the PCBs undergo a series of soldering processes to securely attach the components to the board. {Company Name} utilizes advanced soldering technologies such as reflow soldering and wave soldering to achieve high-quality solder joints and ensure the reliability of the assembled PCBs.In addition to the assembly of the PCBs, {Company Name} also provides a range of testing and inspection services to ensure the quality and reliability of the final product. The company uses advanced testing equipment and inspection techniques to detect any defects or issues in the assembled PCBs, allowing for quick and efficient remediation.One of the key advantages of working with {Company Name} for high volume PCB assembly is its commitment to quality and customer satisfaction. The company has established rigorous quality control processes and standards to ensure that every PCB assembly meets the highest quality and reliability standards.Furthermore, {Company Name} is dedicated to providing a seamless and efficient manufacturing experience for its customers. The company offers comprehensive project management and logistics support to ensure that the high volume PCB assembly process is completed on time and within budget.Overall, {Company Name} has proven itself as a reliable and trusted partner for high volume PCB assembly. With its advanced technologies, commitment to quality, and customer-centric approach, the company has established itself as a leader in the electronics manufacturing industry.In conclusion, high volume PCB assembly is a critical operation in the electronics manufacturing industry, requiring precision, efficiency, and advanced technologies. {Company Name} has excelled in this area, offering high-quality PCB assembly services for a wide range of applications. With its commitment to quality, customer satisfaction, and advanced capabilities, the company has established itself as a trusted partner for high volume PCB assembly.

Professional PCB Fabrication Services for High-Quality Results

Title: Leading PCB Fabrication Services Ensuring Precision and Reliability for Electronic ManufacturersIntroduction:In the rapidly evolving world of electronics manufacturing, finding reliable printed circuit board (PCB) fabrication services is crucial for companies to stay ahead of the curve. {} is a prominent player in the industry, offering high-quality PCB fabrication services that consistently meet the demands of an ever-growing technology landscape. With their commitment to cutting-edge technology, precision manufacturing, and thorough quality control measures, they have emerged as a trusted partner for numerous electronic manufacturers. This news article will delve into the key aspects of their business model that make them a standout choice in the market.Cutting-Edge Technology and Facilities:{} boasts state-of-the-art facilities equipped with the latest machinery and manufacturing technology. With advanced automated production lines and a streamlined production process, they ensure efficient and cost-effective PCB fabrication. By leveraging advanced techniques such as surface mount technology (SMT), ball grid array (BGA), and through-hole technology, they offer a wide range of PCB options for various applications. This enables them to cater to diverse customer requirements, whether for consumer electronics, medical devices, or industrial equipment.Commitment to Quality:The company's commitment to quality is evident in their adherence to strict quality control measures throughout the production process. They employ highly skilled technicians who meticulously inspect and test each PCB for any faults or defects. Through thorough inspections, including X-ray testing, automated optical inspection (AOI), and functional testing, they ensure that each PCB meets the highest industry standards. By prioritizing quality, {} aims to deliver products that not only meet customer expectations but also contribute to the overall reliability and durability of electronic devices.Customization and Technical Support:Recognizing the unique needs of different customers, {} offers customizable PCB fabrication services. Their team of experienced engineers goes the extra mile to understand specific project requirements and design custom PCBs accordingly. Whether it's a complex multilayer board or a simple single-layer design, they leverage their expertise to create tailored solutions that meet individual specifications. Additionally, {} provides comprehensive technical support to address any concerns or challenges faced during the design and fabrication process. This personalized approach ensures that customers' projects are executed seamlessly and efficiently from start to finish.Environmental Responsibility:With a growing emphasis on sustainability, {} is committed to minimizing their environmental footprint. They adhere to strict regulations and best practices to ensure responsible waste management and efficient use of energy and resources. By utilizing eco-friendly materials and implementing recycling programs, they strive to contribute to a greener manufacturing sector. This commitment to sustainability aligns with their vision of not only delivering high-quality PCBs but also embracing a larger corporate social responsibility.Global Reach and Competitive Pricing:{} operates on a global scale, catering to electronic manufacturers around the world. Leveraging strategic partnerships, they offer competitive pricing without compromising on quality. Their ability to meet demanding schedules, coupled with efficient logistics management, ensures timely delivery for customers in diverse geographical locations. From small-scale startups to established electronics giants, {} has gained a reputation for their ability to fulfill both small and large volume orders, making them an ideal choice for businesses of all sizes.Conclusion:With their cutting-edge facilities, commitment to quality, customization options, environmental responsibility, and global reach, {} stands out as a leading PCB fabrication service provider. Their dedication to precision manufacturing and technical expertise enables them to consistently deliver reliable and high-performing PCBs. As the electronics industry continues to evolve, companies can rely on {} to be their trusted partner in meeting the ever-increasing demands of the market.