Top PCB Assembly Service Provider, Offering High-Quality Oshpark Assembly

By:Admin

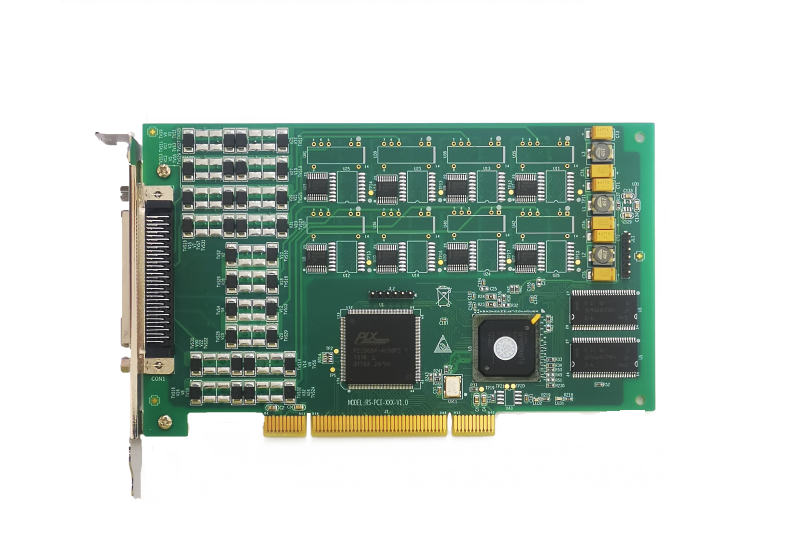

As the world continues to move at a fast pace of technological advancements, the need for sophisticated and reliable electronic systems has never been greater. With complex circuitry and intricate designs, the manufacturing process for these systems can be challenging. Fortunately, Oshpark PCB Assembly has made it their mission to simplify and streamline the manufacturing process for electronics.

Founded in 2013, Oshpark PCB Assembly has rapidly grown to become a top provider of PCB assembly services, thanks to their commitment to quality and customer service. The company offers a wide range of electronic manufacturing services, including PCB assembly, testing, and prototyping. They also provide design verification, material procurement, and full turnkey assembly services, making them a one-stop-shop for all electronics manufacturing needs.

At the core of Oshpark PCB Assembly's success lies their use of state-of-the-art technology, automation, and a team of skilled experts. The company uses the latest tools and software to ensure efficient and accurate production of PCBs. Their equipment is also fully automated, allowing for faster and more precise assembly. With a team of highly qualified technicians and engineers, they offer customized services to meet the unique needs of their clients.

Oshpark PCB Assembly is also committed to quality control, ensuring that every PCB that leaves their factory meets the highest industry standards. The company uses advanced inspection equipment and rigorous testing procedures to guarantee the quality and reliability of their products. They are also constantly updating their processes to improve their efficiency and minimize errors, providing their clients with the best possible service.

In addition to their exceptional services, Oshpark PCB Assembly also offers competitive pricing for their products. With their efficient manufacturing processes, the company is able to keep their costs low, passing the savings onto their clients. They also offer flexible production options, allowing clients to choose the most suitable manufacturing package based on their budget and needs.

Oshpark PCB Assembly has set itself apart from its competitors by providing superior customer service. The company has a team of support staff available 24/7 to address any concerns or queries their clients may have. Their team is highly responsive, ensuring that any issues are resolved quickly, minimizing production delays and downtime.

The company also values open communication with their clients, ensuring that they are involved in every step of the manufacturing process. They offer regular updates on the progress of their projects, and are always available to discuss any changes or modifications that clients may require.

With their commitment to quality, efficiency, and customer service, it comes as no surprise that Oshpark PCB Assembly has earned a reputation as a leading provider of PCB assembly services. Their dedication to simplifying and streamlining the manufacturing process for electronics has helped countless clients save time and money, without compromising on the quality of their products.

In conclusion, Oshpark PCB Assembly has established itself as a trustworthy and reliable partner for electronics manufacturing needs. Their state-of-the-art technology, automation, and experienced team of experts ensure that clients receive top-notch services that meet their unique needs. With their superior customer support and competitive pricing, Oshpark PCB Assembly is the go-to choice for electronics manufacturing solutions.

Company News & Blog

Understanding the Key Benefits of Electronic PCB Assembly for Efficient Product Integration

Title: Electronic PCB Assembly Company, a Pioneer in Advanced Manufacturing Technologies, Sets New Industry StandardsSubtitle: Positioned at the Forefront of Revolutionary PCB Assembly Solutions, Company Remains Committed to Delivering Cutting-Edge Electronic Products[City, Date] - Electronic PCB Assembly Company, a renowned leader in the electronics manufacturing industry, has been setting new benchmarks with its advanced PCB assembly technologies. With a strong emphasis on innovation, quality, and customer satisfaction, the company has consistently positioned itself as a pioneer in delivering state-of-the-art electronic products to businesses across various sectors.Founded with the vision to revolutionize the electronics industry, Electronic PCB Assembly Company has become synonymous with cutting-edge manufacturing solutions and superior customer service. With a relentless drive for innovation and an unwavering commitment to excellence, the company has rapidly established itself as an industry leader.Electronic PCB Assembly Company specializes in providing comprehensive electronic manufacturing services (EMS), catering to businesses ranging from startups to multinational corporations. The company's expertise lies in the assembly of printed circuit boards (PCBs), which serve as the cornerstone for various electronic devices.Utilizing the latest technologies and adhering to stringent quality control measures, Electronic PCB Assembly Company delivers reliable and high-performing PCBs that meet the unique requirements of its diverse clientele. By employing advanced equipment, efficient processes, and highly skilled professionals, the company ensures the production of top-notch circuit boards that exhibit exceptional performance and durability.Moreover, Electronic PCB Assembly Company understands the importance of staying ahead in a dynamic and rapidly changing industry. The company invests extensively in research and development to stay at the forefront of emerging technologies. This commitment to innovation enables the company to offer innovative assembly solutions, designed to meet the challenges of tomorrow's electronic products.One of the key factors contributing to Electronic PCB Assembly Company's success is its customer-centric approach. The company strives to build long-term partnerships with its clients by understanding their specific needs and providing tailored solutions. By closely collaborating with customers throughout the development and production process, Electronic PCB Assembly Company ensures complete transparency and delivers products that meet and exceed expectations.The company's dedication to quality is evident through its adherence to industry-leading certifications and standards. Electronic PCB Assembly Company follows strict manufacturing protocols, including ISO 9001:2015 and IPC-A-610, to guarantee the highest level of quality assurance. These certifications illustrate the company's unwavering commitment to consistently deliver products that meet international quality benchmarks.Furthermore, Electronic PCB Assembly Company is deeply committed to environmental sustainability. The company actively promotes eco-friendly manufacturing practices and complies with global directives aimed at reducing electronic waste. By adopting environmentally conscious approaches, such as proper waste management and responsible disposal processes, Electronic PCB Assembly Company ensures the protection of the environment while contributing to a more sustainable future.In conclusion, Electronic PCB Assembly Company has emerged as a trailblazer in the field of advanced manufacturing technologies. With its innovative approaches, unparalleled expertise, and customer-centric values, the company has successfully set new industry standards. With a firm commitment to quality, innovation, and sustainability, Electronic PCB Assembly Company continues to spearhead the electronics manufacturing industry by delivering cutting-edge electronic products that meet the evolving demands of businesses worldwide.For media inquiries, please contact:[Name][Title][Company Name][Phone number][Email address]About Electronic PCB Assembly Company:Electronic PCB Assembly Company is a leading provider of electronic manufacturing services, specializing in the assembly of printed circuit boards. With a focus on innovation, quality, and customer satisfaction, the company delivers advanced PCB assembly solutions to businesses across diverse industries. Committed to remaining at the forefront of emerging technologies, Electronic PCB Assembly Company remains dedicated to providing cutting-edge electronic products and fostering long-term partnerships with its clients.

Get Quality PCB Assembly Services for Your Electronic Products

In recent years, the global electronics industry has been on an upward trajectory, with the market expected to reach $2.2 trillion by 2025. This growth has been fueled by rising demand for electronic devices, including smartphones, laptops, and smart home gadgets.As a key player in the electronics industry, PCB assembly services have become more important than ever. PCB assembly services provide companies with high-quality, reliable circuit board assembly that supports their business goals while also ensuring product longevity and customer satisfaction.One company that is making waves in the world of PCB assembly services is {}, a leading manufacturer of high-performance PCB assembly solutions. Comprised of professionals with extensive experience in PCB assembly, the company has built a solid reputation for delivering flexible, customized PCB assembly solutions that meet the unique requirements of each client.{"}'s PCB assembly services are backed by state-of-the-art technology and a team of highly qualified engineers who utilize advanced equipment such as SMT machines, automatic optical inspection (AOI) systems, and flying probe testers to streamline the production process and ensure high quality output.The company provides a wide range of PCB assembly services, including surface mount technology (SMT) assembly, through-hole assembly, and mixed technology assembly, ensuring that clients can choose the ideal assembly method required to meet the standards and specifications of their projects.With {}'s turnkey PCB assembly services, clients do not have to worry about managing every aspect of the project. The company provides a complete range of services, from conceptualization to product delivery, such as PCB layout design, PCB fabrication, component sourcing, and PCB assembly.One of the key benefits of choosing {} as your PCB assembly service partner is that they adhere to the highest industry standards. The company is certified to ISO 9001:2015, which guarantees customers that their products are manufactured according to international standards. Moreover, {} also complies with industry standards such as IPC-610 and IPC-A-600, ensuring that their clients receive the best quality possible.In addition to adhering to high industry standards, the company also offers competitive pricing and fast turnaround times. By streamlining the PCB assembly process and using cutting-edge technology, the company is able to support clients in reducing time-to-market, lowering costs, and improving process efficiency.To ensure that PCB assembly projects are executed smoothly, {} works closely with clients to understand their unique requirements, challenges, and goals. The company also provides a dedicated team of account managers who serve as the primary point of contact for clients, providing timely updates and support throughout the project's lifecycle.In conclusion, PCB assembly services are integral to the electronics industry, and companies that choose {} enjoy numerous benefits. From high-quality output to competitive pricing and fast turnaround times, {} offers a complete range of services that meet the unique requirements of each client.For those looking to collaborate with a PCB assembly service provider that adheres to high industry standards and provides customized solutions, {} is the ideal partner.

Discover the Latest Innovations in Circuit Board Technology - A Look into Advanced EMS Solutions

Title: Cutting-Edge Ems Circuit Board Transforms the Landscape of Electronics ManufacturingIntroduction:In today's fast-paced world, the demand for cutting-edge technology is on the rise, and electronic manufacturing services (EMS) companies are at the forefront of this revolution. One such provider, {company name}, has recently unveiled their latest groundbreaking product – an innovative EMS circuit board that is set to redefine the way electronic devices are manufactured. With its advanced features and unparalleled performance, this circuit board is poised to transform the landscape of electronics manufacturing, bringing forth a new era of efficiency and reliability.Body:1. Overview of {company name}:{Company name} is a leading provider of electronic manufacturing services, specializing in the production of high-quality circuit boards and other electronic components. With a strong focus on innovation and technological advancements, they have consistently delivered cutting-edge solutions to their clients across various industries. Having established a solid reputation as a reliable and forward-thinking company, {company name} continues to push the boundaries of what is possible in the realm of electronics manufacturing.2. The Emergence of the EMS Circuit Board:The recently introduced EMS circuit board by {company name} has generated significant buzz within the industry. This technologically advanced circuit board is designed to enhance the efficiency, performance, and reliability of electronic devices. Equipped with state-of-the-art features, it has the potential to revolutionize the manufacturing process and provide substantial benefits to both manufacturers and end-users.3. Advanced Features and Benefits:The EMS circuit board boasts several groundbreaking features that set it apart from traditional circuit boards. These include:a) Enhanced Durability: The circuit board is engineered using durable materials that can withstand harsh environmental conditions, ensuring longevity and reliability of the electronic devices.b) Improved Heat Dissipation: The advanced design of the circuit board enables efficient heat dissipation, thereby preventing overheating issues and increasing the lifespan of the device.c) Higher Component Density: This new EMS circuit board allows for a higher concentration of electronic components, enabling manufacturers to create smaller and more compact devices without compromising on performance.d) Enhanced Electrical Performance: With reduced signal loss and improved signal integrity, the circuit board ensures optimal electrical performance, resulting in faster data transmission and improved overall functionality.e) Streamlined Manufacturing Process: The advanced design of the EMS circuit board simplifies the manufacturing process, reducing production time and costs, thereby enhancing efficiency and productivity for manufacturers.4. Industry Applications:The application of the EMS circuit board is vast, spanning across various industries. Whether it is consumer electronics, aerospace, telecommunications, automotive, or medical devices, this innovative circuit board can cater to the unique needs of each sector. Its adaptability and versatility make it an ideal choice for manufacturers looking to stay ahead of the curve and deliver cutting-edge products to their customers.5. Future Implications:The introduction of the EMS circuit board by {company name} marks a significant milestone in the evolution of electronics manufacturing. As the industry continues to evolve, this groundbreaking technology has the potential to reshape the way electronic devices are designed and manufactured. Its advanced features and benefits are expected to spur innovation, enhance product performance, and improve overall user experience in the years to come.Conclusion:The EMS circuit board introduced by {company name} epitomizes the spirit of innovation and technological advancement within the electronics manufacturing industry. With its advanced features and benefits, this cutting-edge circuit board has the potential to disrupt traditional manufacturing processes, bringing forth a new era of efficiency, reliability, and compactness. As the demand for high-quality electronic devices continues to soar, {company name} is at the forefront, driving the industry forward with their groundbreaking EMS circuit board.

Quality PCB Assembly House offers efficient services for smooth production

Title: A Leading PCB Assembly House Revolutionizes Electronics ManufacturingIntroduction:In a rapidly evolving technology-driven world, the importance of efficient and reliable Printed Circuit Board (PCB) assembly cannot be overstated. Offering a solution to meet this demand, one prominent PCB assembly house has emerged as an industry leader, spearheading innovation and revolutionizing the electronics manufacturing landscape. With a steadfast commitment to excellence, quality, and customer satisfaction, this company has transformed the way electronics are produced and utilized across various sectors.I. History and Expertise:Established in [year], the PCB assembly house has quickly risen to prominence through its exceptional track record and commitment to technological advancements. With a state-of-the-art manufacturing facility equipped with cutting-edge machinery and a highly skilled workforce, the company has set a benchmark for efficient and high-quality PCB assembly processes.II. Unique Manufacturing Capabilities:The PCB assembly house takes pride in its ability to provide end-to-end solutions that cater to the diverse needs of its clients. From rapid prototyping to high-volume production, the company offers a comprehensive range of services, ensuring that projects are completed with utmost precision and efficiency. By leveraging advanced automation techniques and adhering to stringent quality control measures, the PCB assembly house ensures the production of reliable, durable, and high-performing PCBs.III. Commitment to Quality Assurance:Recognizing the critical role of quality control in the manufacturing process, the company has implemented a rigorous testing regime. Utilizing advanced testing equipment and procedures, each PCB undergoes extensive inspections to ensure conformity to international standards and customer specifications. The assembly house's commitment to quality assurance guarantees that electronic devices produced using their PCBs meet the highest performance standards.IV. Embracing Cutting-edge Technologies:Keeping pace with the rapidly changing technological landscape, the PCB assembly house regularly invests in research and development activities. By collaborating with leading institutions and employing highly skilled engineers, the company stays at the forefront of technological advancements, allowing them to offer innovative solutions to their clients. This forward-thinking approach enables the assembly house to provide PCB designs that optimize performance, functionality, and efficiency.V. Offering Customized Solutions:Recognizing that client requirements vary greatly, the PCB assembly house emphasizes providing tailored solutions. Their team of experienced engineers works closely with clients to develop PCB designs that align with their specific needs, while also considering factors such as size constraints, power consumption, and thermal management. This customer-centric approach ensures that the final product meets and exceeds expectations, effectively addressing unique project requirements.VI. Partnering for Sustainability:In addition to their commitment to technological advancements, the PCB assembly house is equally dedicated to sustainability. Recognizing the industry's impact on the environment, the company employs eco-friendly practices throughout their manufacturing processes. Implementing measures such as recycling programs, waste reduction initiatives, and energy-efficient systems, the assembly house demonstrates its determination to minimize its carbon footprint and contribute to a greener future.Conclusion:As the demand for efficient and high-quality PCB assembly continues to rise, the aforementioned PCB assembly house has emerged as a leading force in the electronics manufacturing industry. Through their dedication to innovation, commitment to quality, and customer-centric approach, they have successfully transformed the manufacturing landscape. By serving as a reliable partner and offering customized solutions, the assembly house has solidified its position as a go-to destination for all PCB assembly needs. With a keen eye on sustainability, the company sets an example for others, combining progressive technologies with environmentally conscious practices to meet the demands of today's market while paving the way for a sustainable future.

Leading Electronics Supplier Launches Innovative Flexible Printed Circuits

Fpc Electronics Acquires Technology Company to Strengthen Its Capabilities in the Electronics IndustryLeading electronics manufacturer, Fpc Electronics, announced today that they have acquired a technology company in order to enhance their capabilities in the electronics industry. The acquisition will enable Fpc Electronics to expand their product offerings and grow their market share.The name of the technology company was not disclosed, but Fpc Electronics stated that the acquisition was a strategic move to improve their position in the market. The acquisition will help Fpc Electronics to accelerate their innovation and bring new products to market faster.Fpc Electronics is a leading manufacturer of flexible printed circuits (FPC) and rigid-flex circuits. With over 15 years of experience in the industry, Fpc Electronics has become a trusted partner for customers across a variety of industries, including automotive, medical, and telecommunications.“We are very excited about this acquisition and what it means for our company,” said the CEO of Fpc Electronics. “The technology company we acquired has a strong reputation for innovation and has developed some impressive new technologies that will help us to improve our products and services.”The acquisition will also help Fpc Electronics to expand their manufacturing capabilities. The technology company has state-of-the-art manufacturing facilities that will enable Fpc Electronics to increase production and improve efficiency. This will ultimately help Fpc Electronics to better serve their customers and meet the growing demand for their products.“With this acquisition, we are positioning ourselves for continued growth and success in the electronics industry,” added the CEO. “We believe that the combination of our expertise in FPC and rigid-flex circuits, along with the new technologies that we have acquired, will enable us to provide our customers with even more value.”Fpc Electronics has been a pioneer in the electronics industry, introducing new technologies and products that have helped to shape the industry. With this acquisition, Fpc Electronics is once again demonstrating their commitment to innovation and their dedication to meeting the needs of their customers.“We are proud to be a leader in the electronics industry and we are excited about the future of our company,” said the CEO. “We believe that this acquisition will help us to achieve even greater success in the years ahead.”The acquisition is expected to be completed by the end of the year, subject to regulatory approvals. Following the completion of the acquisition, Fpc Electronics will begin integrating the new technologies into their products and services. They will also work to increase production capabilities and improve efficiency in their manufacturing processes.Overall, this acquisition is a significant milestone for Fpc Electronics and a positive development for the electronics industry. With this acquisition, Fpc Electronics is well positioned to continue driving innovation, expanding their market share, and delivering value to their customers.

Expert PCB Manufacturing Solutions in the Bay Area" becomes "Top-rated PCB Manufacturing in the Bay Area

Title: Pioneering PCB Manufacturing in the Bay Area Revolutionizes Electronic IndustryIntroduction:In the heart of the innovation hub that is the Bay Area, a leading manufacturer has emerged to disrupt the electronic industry. Through their cutting-edge facilities and commitment to quality, this company has quickly become a game-changer in the world of printed circuit board (PCB) manufacturing. With an unwavering dedication to innovation and customer satisfaction, this visionary manufacturer is establishing itself as a top-tier provider of PCB solutions.Body:1. The Bay Area's Thriving Electronics Landscape:The Bay Area has long been known as a hotbed for technology and innovation, with countless startups and established companies constantly pushing boundaries to create groundbreaking products. With the rise of Internet of Things (IoT) devices, wearables, autonomous vehicles, and advanced medical equipment, the demand for high-quality PCBs has skyrocketed. Recognizing this growth potential, our featured manufacturer entered the scene with a mission to fulfill the increasing demand for innovative PCB solutions.2. Advanced Manufacturing Facilities:The company boasts a state-of-the-art manufacturing facility in the heart of the Bay Area, equipped with cutting-edge machinery and technology. Committed to staying at the forefront of industry advancements, they continually invest in new equipment and software to ensure the highest level of precision, efficiency, and quality in their PCB manufacturing process.3. Embracing Industry Standards:Compliance with industry standards is paramount for any PCB manufacturer. This company exceeds expectations by adhering to stringent international standards, including ISO 9001, ISO 14001, and IPC Class 3. By maintaining these certifications, they ensure the manufacturing of PCBs that meet the highest quality and reliability standards.4. Emphasis on Research and Development:Innovation is the lifeblood of this pioneering manufacturer. To stay ahead of the curve, they place a strong emphasis on research and development, actively collaborating with industry partners and academic institutions to drive forward-thinking solutions. By fostering a culture of innovation and creativity, they continuously push the boundaries of PCB manufacturing, offering cutting-edge solutions to their customers.5. Diverse Product Range:With a customer-centric approach, this PCB manufacturer offers a diverse range of products to cater to various industries such as aerospace, automotive, consumer electronics, telecommunications, medical, and more. Whether it's single-sided, double-sided, flexible, or rigid-flex PCBs, they have the capabilities to provide tailored solutions to meet clients' specific requirements.6. Seamless Customer Experience:Understanding the importance of exceptional customer service, this manufacturer takes pride in offering a seamless experience from start to finish. From initial design consultation to final delivery, they are committed to providing timely communication, personalized attention, and technical guidance to ensure each client's unique needs are met.7. Eco-Friendly Practices:As responsible corporate citizens, the company places a strong emphasis on sustainability. They promote eco-friendly practices by optimizing production processes to minimize waste, recycling materials whenever possible, and reducing environmental impact. Their commitment to sustainability extends beyond manufacturing, ensuring that PCBs are produced ethically and responsibly.Conclusion:In the dynamic landscape of the Bay Area, PCB manufacturing has taken a significant leap forward with this visionary company's innovative approach. Their state-of-the-art manufacturing facilities, commitment to quality and industry standards, focus on research and development, diverse product range, seamless customer experience, and eco-friendly practices distinguish them as trailblazers. As they continue to redefine the boundaries of PCB manufacturing, their impact on the electronic industry becomes increasingly profound, cementing their status as a leading provider of cutting-edge PCB solutions in the Bay Area and beyond.

Efficient Assembly Line Layout Tactics Boost Productivity and Workflow

Assembly Line Layout Revolutionizes Manufacturing Process, Boosting Efficiency and ProductivityIn the competitive world of manufacturing, companies are constantly seeking innovative solutions to enhance their production processes. One groundbreaking approach that has recently gained significant attention is the Assembly Line Layout. This revolutionary concept has the power to transform the manufacturing industry, revolutionizing how products are made and ultimately improving efficiency, productivity, and profitability.Assembly Line Layout, or ALL, is a systematic arrangement of workstations and equipment that allows for a smooth and efficient flow of work from start to finish. It is designed to maximize efficiency by minimizing unnecessary movements, reducing assembly time, and streamlining the entire manufacturing process.By carefully organizing workstations in a sequential order, the Assembly Line Layout eliminates unnecessary backtracking and reduces travel time, resulting in a significant reduction in production time. This arrangement ensures that workers and materials are efficiently utilized and that the production line operates at its maximum potential.With the implementation of ALL, manufacturers can streamline their operations, reduce bottlenecks, and increase overall productivity. By breaking down the production process into smaller tasks, each worker becomes specialized in their assigned task, leading to improved proficiency and speed. This specialization allows for better control over quality, as workers can focus on perfecting their specific task rather than being overwhelmed by multiple responsibilities.One major advantage of the Assembly Line Layout is its scalability. As production demands fluctuate, manufacturers can easily adjust the number of workstations and workers according to their needs. This flexibility allows companies to rapidly adopt changes in demand, ensuring that production keeps pace with market requirements without compromising efficiency or quality.Moreover, the ALL concept promotes standardization, leading to increased product consistency and quality control. With predefined workstations and equipment setups, manufacturers can establish standardized procedures for each task, reducing the risk of human error and ensuring that products meet the highest quality standards. This not only improves customer satisfaction but also reduces costs associated with defective products and rework.The benefits of the Assembly Line Layout extend beyond the manufacturing floor. By optimizing the production process, manufacturers can decrease lead times and deliver products to market faster. This improved time-to-market enables companies to meet customer demands promptly, gain a competitive edge, and capitalize on market opportunities.In addition to the efficiency gains, the Assembly Line Layout facilitates better workflow management. With a clear visual representation of the production process and the ability to monitor progress at each workstation, managers can easily identify bottlenecks and address them proactively. This real-time information empowers decision-makers to make data-driven decisions, optimize resource allocation, and improve overall operational performance.While the Assembly Line Layout offers undeniable advantages, its successful implementation requires careful planning and consideration. Manufacturers must analyze their production requirements, assess the suitability of their product for an assembly line setup, and invest in appropriate equipment and training for their workforce. Additionally, companies must ensure that safety measures are in place to protect workers and prevent accidents in the fast-paced environment of an assembly line.As the manufacturing landscape becomes increasingly competitive, companies must explore innovative solutions to stay ahead. The Assembly Line Layout presents a compelling opportunity for manufacturers to optimize their operations, enhance productivity, and improve profitability. By adopting this revolutionary approach, manufacturers can pave the way for a more efficient and successful future in an ever-evolving industry.

Exploring the Advantages of Multi Layer Circuit Boards for Enhanced Performance

Multi-Layer Circuit Board Revolutionizes Electronics IndustryIn the fast-paced world of electronics, innovation is the key to success. Rapid advancements in technology have enabled the development of increasingly complex devices, pushing the boundaries of what is possible. One groundbreaking innovation that is set to revolutionize the industry is the Multi-Layer Circuit Board (MLCB), a state-of-the-art technology that promises to enhance performance, durability, and efficiency in electronic devices.Developed by an industry-leading technology company, the MLCB is a significant breakthrough in circuit board design. Traditional circuit boards consist of a single layer of conductive material, limiting the amount of circuitry that can be integrated onto the board. However, MLCBs feature multiple layers of conductive material stacked on top of each other, allowing for a vast increase in circuit density and functionality. This technological advancement opens up a world of possibilities for electronics manufacturers, enabling them to create smaller, more powerful, and more capable devices.One of the key advantages of MLCBs lies in their ability to efficiently manage heat dissipation. Electronics generate a substantial amount of heat during operation, which can lead to performance degradation and even the failure of critical components. MLCBs utilize advanced thermal management techniques, such as the integration of thermally conductive materials and heat sinks, to dissipate heat more effectively and ensure optimal performance even under high loads. This breakthrough greatly enhances the reliability and longevity of electronic devices, reducing the need for frequent maintenance and replacements.Moreover, the increased circuit density of MLCBs allows for greater integration of electronic components onto a single board. This not only reduces the overall size of electronic devices but also improves their overall functionality. For example, smartphones equipped with MLCBs can house more advanced features, such as larger memory capacity, sophisticated camera systems, and enhanced processing power. This technology revolutionizes the way electronic devices are designed, offering manufacturers the opportunity to pack more innovative features into smaller and more refined form factors.The applications of MLCBs span across a multitude of industries. In the automotive sector, MLCBs enable the development of advanced driver assistance systems, smart sensors, and autonomous driving technologies. These circuit boards also find extensive use in the aerospace industry, where lightweight and compact electronics are crucial for saving space and reducing fuel consumption. Additionally, MLCBs play a vital role in the medical field, facilitating the creation of sophisticated medical devices, diagnostic equipment, and wearable health trackers. The possibilities are endless.Furthermore, the adoption of MLCBs is expected to drive significant cost savings in the electronics manufacturing process. The increased functionality and compactness of these boards mean that fewer components are required, resulting in reduced material and assembly costs. Additionally, the enhanced durability of MLCBs reduces the likelihood of failures and the associated costs of repairs or replacements. These cost-effective advantages make MLCBs an attractive choice for manufacturers looking to streamline their production processes and offer more competitive products in the market.The company behind this groundbreaking innovation, {}, has been at the forefront of technological advancements for decades. Known for their expertise and commitment to excellence, they have consistently delivered cutting-edge solutions that have shaped the electronics industry. By introducing the Multi-Layer Circuit Board, the company once again proves its dedication to driving innovation and propelling the industry forward.In conclusion, the Multi-Layer Circuit Board is set to transform the electronics industry. With its increased circuit density, efficient heat dissipation, and cost-effective advantages, MLCBs offer unparalleled possibilities for manufacturers to create smaller, more powerful, and more capable electronic devices. This groundbreaking technology, developed by {}, promises to shape the future of electronics and pave the way for a new era of innovation.

Essential Guide to Understanding PCB Board Schematic Designs: Simplified & Comprehensive Explanation

PCB Board Schematic – The Way Forward in Electronic ManufacturingThe demand for electronic devices has skyrocketed to an unprecedented level in the last decade. This, in turn, gave rise to the electronic manufacturing industry, which has rapidly evolved to produce high-quality hardware for use in devices such as smartphones, laptops, and televisions, among others.One essential component in the electronic manufacturing process is the Printed Circuit Board (PCB). It is a board that connects and houses electronic components such as capacitors, resistors, and microchips. A PCB comes in various types and is essential in the design of electronic devices.The PCB functions by providing an electrical pathway for the components to connect, communicate, and power each other. It also ensures the stability and durability of the device. To achieve optimal results, every PCB design goes through a process called schematic capture.Schematic capture is the process of creating a blueprint of the PCB design, which is fundamental in ensuring that all the components are in the right position and orientation. This process also makes sure that a particular design meets certain electrical and mechanical specifications.With the importance of schematic capture, PCB Board Schematic (need remove brand name) has become the go-to partner for many electronics manufacturers. They provide high-quality schematic capture services tailored to meet the specific specs of each client. The company is committed to delivering the best PCB services and ensuring that clients achieve their product designs' desired functionalities.The PCB Board Schematic (need remove brand name) company has an experienced team of engineers, designers, and project managers who work tirelessly to ensure that all clients' specifications are met. Their team is highly skilled in both analog and digital electronic designs, and they have a wealth of knowledge in creating schematics for various projects.PCB Board Schematic (need remove brand name) understands the importance of using the latest design software and technology in the electronic industry. They use the latest software such as Altium Designer and CADSTAR to ensure the accuracy and efficiency of the schematic capture process. This approach has not only enabled the company to stay ahead of the competition but also made their services affordable and accessible to clients from all over the world.Besides schematic capture, PCB Board Schematic (need remove brand name) also offers other PCB design services such as routing, manufacturing, and assembly. They have state-of-the-art manufacturing machines that ensure the highest quality, precision, and consistency in all their designs.PCB Board Schematic (need remove brand name)'s success is not only attributed to the quality of their services but also their commitment to customer satisfaction. They value every client and aim to build a long-term and transparent relationship with each one of them.In conclusion, the electronic manufacturing industry is growing each day, and the need for high-quality PCBs is on the rise. PCB Board Schematic (need remove brand name) is committed to providing the best PCB services and ensuring that every client achieves the desired functionalities of their product designs. Their experienced team, use of the latest technology, and commitment to customer satisfaction make them the go-to partner for all your PCB schematic capture and design projects.

Top Tips for Optimizing Your PCBA for Enhanced Performance

[Company Name] Introduces Cutting-Edge PCBA Technology Revolutionizing the Electronics Industry[City, Date] - [Company Name], a leading provider of innovative technologies, has unveiled their latest breakthrough in Printed Circuit Board Assembly (PCBA). With the aim of transforming the electronics industry, [Company Name] has developed a state-of-the-art PCBA solution that sets new standards in efficiency, reliability, and performance.PCBAs serve as the backbone of electronic devices, enabling them to function seamlessly. As technology advances, the demand for smaller, faster, and more powerful electronics continues to grow. [Company Name]'s revolutionary PCBA technology promises to address these demands by offering a ground-breaking solution.With years of research and development, [Company Name] has successfully integrated cutting-edge components and manufacturing processes to bring forth a PCBA that surpasses industry expectations. The company's commitment to innovation and relentless pursuit of excellence has enabled them to create a product that significantly improves upon existing technology.One of the key features of [Company Name]'s PCBA solution is its enhanced efficiency. Traditional PCBAs often suffer from reliability issues, inefficient power usage, and limited functionality. However, [Company Name] has pioneered a design that maximizes power utilization while minimizing energy waste, resulting in improved performance and reduced operational costs.Furthermore, the company's PCBA incorporates advanced components that offer superior functionality. By utilizing top-of-the-line materials and components, [Company Name] ensures enhanced durability, increased resistance to external factors, and extended lifespan. Consequently, this breakthrough technology is likely to reduce the need for frequent repairs and replacements, saving both time and money for end-users.Another remarkable aspect of [Company Name]'s PCBA is its versatility. The company's comprehensive research and development efforts have resulted in a flexible design that supports a wide range of electronic applications. Whether it be consumer electronics, automotive systems, or industrial equipment, [Company Name]'s PCBA can be seamlessly integrated into various devices, paving the way for greater convenience and adaptability in all industries.In addition to these exceptional qualities, [Company Name]'s PCBA also upholds the highest industry standards in terms of safety and compliance. The company strictly adheres to rigorous quality control procedures throughout the manufacturing process, ensuring that their PCBA meets and exceeds international regulations. This commitment to safety ensures that end-users can trust the reliability and security of [Company Name]'s products.To support the widespread adoption of their revolutionary PCBA, [Company Name] offers comprehensive technical support and assistance to their customers. Their experienced team of engineers and technicians provide guidance, customization options, and troubleshooting services to ensure seamless integration and optimal performance.The introduction of [Company Name]'s PCBA technology has garnered immense excitement and anticipation within the electronics industry. Industry experts predict that this revolutionary solution will serve as a catalyst for innovation, further propelling the advancements in various sectors including consumer electronics, automotive technology, and industrial automation.As [Company Name] continues to push the boundaries of technological innovation, their PCBA is set to transform the electronics industry. With its enhanced efficiency, superior functionality, and adherence to safety standards, it is clear that [Company Name]'s PCBA will play a pivotal role in shaping the electronics landscape in the coming years.