Efficient Testing Solutions for Pcba Components

By:Admin

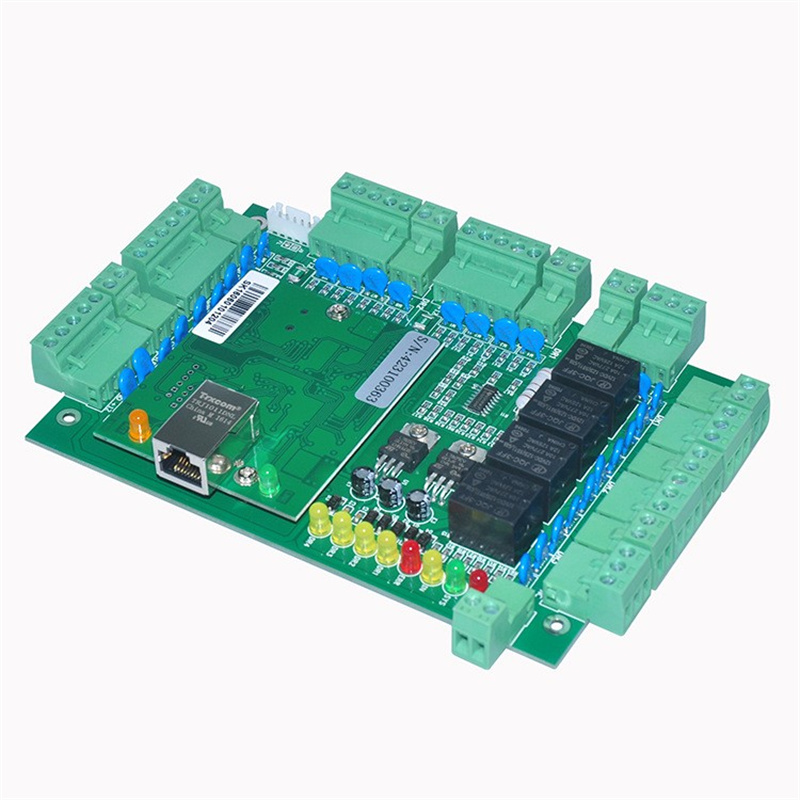

The company, which has been a leader in the electronics manufacturing industry for over 20 years, specializes in providing comprehensive PCBA testing solutions. With state-of-the-art equipment and a team of experienced technicians, they offer a range of testing services to ensure the quality and reliability of PCBA.

One of the key testing methods offered by the company is the Automated Optical Inspection (AOI). This technology uses advanced cameras and algorithms to detect any potential defects in the PCB assembly, such as missing components, misaligned parts, or soldering issues. The AOI test provides a fast and accurate assessment of the PCBA, allowing for quick identification and resolution of any issues.

In addition to AOI, the company also offers In-Circuit Testing (ICT) services. ICT is a comprehensive test that checks the electrical performance of individual components on the PCB. By applying controlled voltages and currents to specific points on the board, ICT can identify any faulty components or connections, ensuring the overall functionality of the PCBA.

Furthermore, the company provides Functional Testing to verify the complete functionality of the PCBA. This test simulates real-world operating conditions to ensure that the assembly performs as intended. By subjecting the PCB to various input signals and monitoring the output, Functional Testing helps to validate the overall integrity and performance of the electronic device.

The company's testing services are not limited to these methods. They also offer custom testing solutions tailored to the specific needs of their clients. Whether it's environmental testing, vibration analysis, or custom test development, the company is committed to delivering accurate and reliable testing services to its customers.

In addition to their cutting-edge testing capabilities, the company places a strong emphasis on quality and customer satisfaction. They adhere to strict quality control measures throughout the testing process, ensuring that every PCBA meets the highest standards of performance and reliability. Customer satisfaction is at the core of their business, and they work closely with clients to understand their testing requirements and provide tailored solutions to meet their needs.

Furthermore, the company is dedicated to staying at the forefront of technological advancements in the electronics manufacturing industry. They continuously invest in research and development to enhance their testing capabilities and stay ahead of industry trends. By utilizing the latest technology and methodologies, they are able to offer state-of-the-art testing solutions that meet the evolving needs of their clients.

As a trusted partner in the electronics manufacturing industry, the company has established a strong reputation for delivering reliable and comprehensive PCBA testing services. Their commitment to quality, innovation, and customer satisfaction sets them apart as a leader in the field.

In conclusion, PCBA testing is a critical step in the electronics manufacturing process, and the company's advanced testing solutions ensure the quality and reliability of PCB assemblies. With a focus on quality, innovation, and customer satisfaction, they continue to be a trusted partner for PCBA testing needs.

Company News & Blog

Ultimate Guide to Flexible PCB Materials

Flexible PCB Material Revolutionizes Electronics IndustryIn today's fast-paced world of technology, the demand for smaller, lighter, and more flexible electronic devices is constantly growing. As a result, the materials used in electronics manufacturing have had to evolve to meet these demands. One such material that is revolutionizing the industry is flexible PCB material.Flexible PCB material, also known as flex PCB, is a type of electronic circuit that can be bent, twisted, and folded without affecting its functionality. This is made possible by using a flexible substrate material, such as polyimide, instead of the traditional rigid fiberglass material used in standard PCBs. This flexibility allows for the creation of electronic devices that can conform to unconventional shapes and designs, ultimately opening up a world of possibilities for innovation in the electronics industry.{} is a leading manufacturer of flexible PCB material, with years of experience in the industry. The company has been at the forefront of developing and producing high-quality flexible PCB material that has been used in a wide range of electronic devices, from smartphones and wearables to automotive and aerospace applications. With a strong focus on research and development, {} has been able to push the boundaries of what is possible with flexible PCB material, opening up new opportunities for their customers to create more advanced and innovative products.One of the key advantages of using flexible PCB material is its ability to reduce the overall size and weight of electronic devices. Traditional rigid PCBs are limited by their fixed shape and size, often requiring additional space for connectors and cables. With flexible PCB material, electronic devices can be designed to fit into smaller and more compact form factors, making them more portable and convenient for consumers.In addition to its flexibility, flexible PCB material also offers improved durability and reliability compared to traditional rigid PCBs. The flexible substrate material used in flex PCBs is more resistant to vibration, shock, and thermal expansion, making it ideal for use in harsh environments or in applications where reliability is critical.Furthermore, the use of flexible PCB material allows for more efficient assembly processes, reducing manufacturing time and cost. The flexibility of the material means that electronic devices can be manufactured using automated assembly techniques, simplifying the production process and increasing overall productivity.As the demand for flexible electronic devices continues to grow, the need for high-quality flexible PCB material is becoming increasingly important. With its extensive experience and expertise in the field, {} is well-positioned to meet this demand and drive innovation in the electronics industry.Looking ahead, it is clear that flexible PCB material will play a crucial role in the future of electronics manufacturing. With the ability to create smaller, lighter, and more durable electronic devices, the possibilities for innovation are endless. As more companies embrace the use of flexible PCB material in their products, we can expect to see a new wave of advanced and revolutionary electronic devices hitting the market in the years to come.In conclusion, the development and production of flexible PCB material by {} signifies a major advancement in the electronics industry. With its ability to create smaller, lighter, and more durable electronic devices, flexible PCB material is revolutionizing the way electronic devices are designed and manufactured. As the demand for flexible electronics continues to grow, it is clear that {} will continue to play a key role in driving innovation and shaping the future of the industry.

Customized Printed Circuit Board Manufacturer – All You Need to Know About Prototypes

Proto Pcb, a leading manufacturer of printed circuit boards, has recently announced a major breakthrough in the field of electronic component manufacturing. The company, known for its innovative and cutting-edge technologies, has developed a revolutionary new process that promises to transform the way printed circuit boards are produced. This development represents a significant advancement in the industry and has the potential to greatly impact the electronic component manufacturing supply chain.Proto Pcb has been a key player in the electronic component manufacturing industry for over two decades. The company has consistently demonstrated its commitment to innovation and has a track record of developing state-of-the-art technologies that push the boundaries of what is possible in the field.The new process developed by Proto Pcb is a game-changer in the printed circuit board manufacturing industry. This innovative method promises to revolutionize the way printed circuit boards are produced, significantly reducing production costs and increasing efficiency. By streamlining the manufacturing process, Proto Pcb expects to deliver higher quality products at a faster pace, ultimately benefiting consumers and the industry as a whole.This breakthrough is the result of years of research and development by Proto Pcb's team of highly skilled engineers and scientists. The company has invested significant resources into developing this new process, recognizing the potential impact it could have on the industry. The successful development of this revolutionary manufacturing process is a testament to Proto Pcb's dedication to pushing the boundaries of what is possible in electronic component manufacturing.The implications of this breakthrough are far-reaching. By introducing this new process, Proto Pcb is poised to disrupt the traditional methods of printed circuit board manufacturing. The company's innovative approach has the potential to set a new standard for electronic component manufacturing, leading to a more efficient and cost-effective supply chain.In addition to the potential impact on the industry, this breakthrough is also expected to benefit consumers. With a more efficient and cost-effective manufacturing process, Proto Pcb will be able to deliver higher quality printed circuit boards at a more competitive price. This could lead to cost savings for manufacturers and ultimately result in more affordable electronic devices for consumers.Proto Pcb's commitment to innovation and continuous improvement has been a driving force behind this breakthrough. The company has a long history of pioneering new technologies and this latest development is a testament to its ongoing efforts to stay at the forefront of the electronic component manufacturing industry.As a leader in the field, Proto Pcb has a reputation for delivering high-quality products and providing exceptional customer service. The company's dedication to excellence has earned it a strong reputation and a loyal customer base. With this latest breakthrough, Proto Pcb is once again demonstrating its commitment to delivering innovative solutions that meet the evolving needs of the industry.The impact of this breakthrough on the electronic component manufacturing industry is expected to be profound. Proto Pcb's new process has the potential to transform the way printed circuit boards are produced, leading to a more efficient and cost-effective supply chain. This development is a significant step forward for the industry and further solidifies Proto Pcb's position as a leader in electronic component manufacturing.In conclusion, Proto Pcb's groundbreaking new manufacturing process represents a major advancement in the field of electronic component manufacturing. This innovative approach has the potential to transform the industry, leading to more efficient and cost-effective production of printed circuit boards. With this latest breakthrough, Proto Pcb continues to demonstrate its commitment to innovation and excellence, setting a new standard for the electronic component manufacturing industry.

Guide to Multi Layer PCB Design: Key Considerations and Best Practices

Multi Layer PCB Design: Revolutionizing Electronic Manufacturing In the ever-evolving world of electronic manufacturing, the design and production of printed circuit boards (PCBs) play a crucial role in the development of advanced and innovative products. Today, the demand for more complex and efficient PCBs is on the rise, and companies like {company name} are at the forefront of meeting this demand with their cutting-edge multi layer PCB design technology.{Company name}, a leading provider of electronic manufacturing solutions, has been a pioneer in the development of multi layer PCBs. With a strong focus on research and development, the company has continuously pushed the boundaries of PCB design to create products that are smaller, lighter, and more technologically advanced.Multi layer PCBs are a type of circuit board that consist of multiple layers of copper traces and insulation material sandwiched together. This design allows for a higher density of components, more complex interconnects, and better thermal management, making them ideal for a wide range of applications such as aerospace, medical devices, telecommunications, and consumer electronics.One of the key advantages of multi layer PCBs is their ability to accommodate the increasing demands for miniaturization in electronic devices. With the integration of more components into smaller spaces, multi layer PCBs enable the development of more compact and portable devices without compromising on performance.In addition, multi layer PCBs offer improved signal integrity and reduced electromagnetic interference, resulting in more reliable and efficient electronic systems. These factors are particularly important in industries such as aerospace and medical devices, where safety and reliability are paramount.{Company name} has been at the forefront of multi layer PCB design, offering a range of advanced capabilities to meet the diverse needs of their clients. Their state-of-the-art manufacturing facilities and advanced equipment allow them to produce multi layer PCBs with high precision and quality.Furthermore, {company name} is committed to providing customized solutions to their clients, ensuring that each multi layer PCB design is tailored to meet the specific requirements of the end product. This level of customization is crucial in industries where unique and specialized designs are necessary to meet the demands of complex applications.The company’s expertise in multi layer PCB design has not only revolutionized electronic manufacturing but has also opened up new possibilities for the development of advanced technologies. The ability to integrate more components into smaller spaces has paved the way for the development of increasingly sophisticated electronic devices, from high-performance computing systems to advanced medical instruments.Moreover, the environment-friendly initiatives taken by {company name} in their production processes underscore their commitment to sustainable and responsible manufacturing practices. By reducing waste and energy consumption, the company is contributing to a greener and more sustainable future for the electronic manufacturing industry.In conclusion, multi layer PCB design has undoubtedly transformed the electronic manufacturing landscape, and companies like {company name} are leading the way in this technological revolution. With their advanced capabilities, commitment to innovation, and dedication to meeting the specific needs of their clients, {company name} continues to drive the development of more advanced, efficient, and reliable electronic devices. As the demand for smaller, lighter, and more powerful electronic products continues to grow, multi layer PCB design will undoubtedly play a crucial role in shaping the future of electronic manufacturing.

Discover the Latest Innovations in Circuit Board Technology - A Look into Advanced EMS Solutions

Title: Cutting-Edge Ems Circuit Board Transforms the Landscape of Electronics ManufacturingIntroduction:In today's fast-paced world, the demand for cutting-edge technology is on the rise, and electronic manufacturing services (EMS) companies are at the forefront of this revolution. One such provider, {company name}, has recently unveiled their latest groundbreaking product – an innovative EMS circuit board that is set to redefine the way electronic devices are manufactured. With its advanced features and unparalleled performance, this circuit board is poised to transform the landscape of electronics manufacturing, bringing forth a new era of efficiency and reliability.Body:1. Overview of {company name}:{Company name} is a leading provider of electronic manufacturing services, specializing in the production of high-quality circuit boards and other electronic components. With a strong focus on innovation and technological advancements, they have consistently delivered cutting-edge solutions to their clients across various industries. Having established a solid reputation as a reliable and forward-thinking company, {company name} continues to push the boundaries of what is possible in the realm of electronics manufacturing.2. The Emergence of the EMS Circuit Board:The recently introduced EMS circuit board by {company name} has generated significant buzz within the industry. This technologically advanced circuit board is designed to enhance the efficiency, performance, and reliability of electronic devices. Equipped with state-of-the-art features, it has the potential to revolutionize the manufacturing process and provide substantial benefits to both manufacturers and end-users.3. Advanced Features and Benefits:The EMS circuit board boasts several groundbreaking features that set it apart from traditional circuit boards. These include:a) Enhanced Durability: The circuit board is engineered using durable materials that can withstand harsh environmental conditions, ensuring longevity and reliability of the electronic devices.b) Improved Heat Dissipation: The advanced design of the circuit board enables efficient heat dissipation, thereby preventing overheating issues and increasing the lifespan of the device.c) Higher Component Density: This new EMS circuit board allows for a higher concentration of electronic components, enabling manufacturers to create smaller and more compact devices without compromising on performance.d) Enhanced Electrical Performance: With reduced signal loss and improved signal integrity, the circuit board ensures optimal electrical performance, resulting in faster data transmission and improved overall functionality.e) Streamlined Manufacturing Process: The advanced design of the EMS circuit board simplifies the manufacturing process, reducing production time and costs, thereby enhancing efficiency and productivity for manufacturers.4. Industry Applications:The application of the EMS circuit board is vast, spanning across various industries. Whether it is consumer electronics, aerospace, telecommunications, automotive, or medical devices, this innovative circuit board can cater to the unique needs of each sector. Its adaptability and versatility make it an ideal choice for manufacturers looking to stay ahead of the curve and deliver cutting-edge products to their customers.5. Future Implications:The introduction of the EMS circuit board by {company name} marks a significant milestone in the evolution of electronics manufacturing. As the industry continues to evolve, this groundbreaking technology has the potential to reshape the way electronic devices are designed and manufactured. Its advanced features and benefits are expected to spur innovation, enhance product performance, and improve overall user experience in the years to come.Conclusion:The EMS circuit board introduced by {company name} epitomizes the spirit of innovation and technological advancement within the electronics manufacturing industry. With its advanced features and benefits, this cutting-edge circuit board has the potential to disrupt traditional manufacturing processes, bringing forth a new era of efficiency, reliability, and compactness. As the demand for high-quality electronic devices continues to soar, {company name} is at the forefront, driving the industry forward with their groundbreaking EMS circuit board.

Understanding the Definition of PCB Design

Pcb Design Meaning, a crucial aspect of modern electronics manufacturing, plays a vital role in the performance and reliability of electronic devices. A well-designed printed circuit board (PCB) is essential for ensuring proper functionality and efficiency in a wide range of electronic products, from consumer electronics to industrial equipment. In today's fast-paced technological landscape, the demand for high-quality PCB design services is at an all-time high, driving the growth of companies such as {}.{} is a leading provider of PCB design services, specializing in delivering innovative and reliable solutions for a diverse clientele. With a team of experienced and skilled engineers, the company has established a strong reputation for its commitment to excellence and customer satisfaction. By leveraging cutting-edge design tools and methodologies, {} has been able to meet the evolving demands of the electronics industry and provide tailored solutions that meet the unique requirements of each client.The importance of PCB design cannot be overstated, as it directly impacts the performance, functionality, and cost-effectiveness of electronic devices. A well-designed PCB layout is essential for minimizing signal interference, reducing manufacturing costs, and maximizing the efficiency of electronic circuits. Additionally, proper PCB design is critical for ensuring compliance with industry standards and regulations, as well as for meeting the specific needs of different applications and markets.In this context, {} has positioned itself as a trusted partner for companies seeking high-quality PCB design services. The company's comprehensive approach to PCB design encompasses all aspects of the process, from initial concept development to prototype testing and production. By working closely with clients, {} ensures that the final PCB design meets the required specifications and performance parameters, while also optimizing for cost and manufacturability.One of the key strengths of {} lies in its ability to integrate advanced design techniques, such as high-speed digital design, RF/microwave design, and thermal management, into the PCB design process. This enables the company to address the increasingly complex requirements of modern electronic devices, including those with stringent performance and reliability criteria. By staying at the forefront of technological advancements, {} is able to offer innovative solutions that set new benchmarks for PCB design excellence.Furthermore, {} prides itself on its commitment to quality and reliability. The company follows rigorous quality control processes throughout the PCB design lifecycle, ensuring that each design meets the highest standards of performance and reliability. By leveraging its extensive expertise and industry best practices, {} is able to deliver PCB designs that exceed client expectations and withstand the rigors of real-world operating conditions.As a company at the forefront of PCB design innovation, {} is well-positioned to capitalize on the growing demand for high-quality design services in the electronics industry. With its proven track record of success and a dedication to continuous improvement, {} is poised to remain a valuable partner for companies seeking exceptional PCB design solutions.In conclusion, PCB design meaning is a critical aspect of modern electronics manufacturing, and companies like {} are playing a pivotal role in driving innovation and excellence in this field. By delivering cutting-edge design solutions that align with the evolving demands of the electronics industry, {} is helping its clients stay ahead of the competition and achieve success in their respective markets. With its unwavering commitment to quality, innovation, and customer satisfaction, {} is well-positioned to continue its leadership in the highly competitive PCB design services sector.

High-Quality PCB Printing and Assembly Services for Your Business

Pcb Printing And Assembly Company Set to Revolutionize the Electronic IndustryIn the fast-paced world of electronics, the need for high-quality and efficient printed circuit board (PCB) printing and assembly services has never been more critical. This is where the innovative solutions provided by {company name} come into play.{Company name} is a leading provider of PCB printing and assembly services, offering a wide range of cutting-edge solutions to meet the diverse needs of the electronic industry. With a strong focus on advanced technology and innovative processes, the company has established itself as a trusted partner for businesses looking to streamline their PCB production processes.The company prides itself on its state-of-the-art manufacturing facilities, equipped with the latest machinery and technology to ensure the highest quality and precision in every PCB produced. From single-layer to multi-layer PCBs, {company name} has the capability to handle projects of varying complexities with ease.One of the key factors that set {company name} apart from its competitors is its commitment to quality and reliability. The company has implemented rigorous quality control measures at every stage of the production process to ensure that each PCB meets the highest industry standards. This unwavering dedication to quality has earned {company name} a stellar reputation in the industry.{Company name} also recognizes the importance of being environmentally conscious in its operations. The company has implemented eco-friendly manufacturing practices and adheres to strict environmental regulations to minimize its carbon footprint. This commitment to sustainability has not only garnered praise from industry insiders but has also resonated with businesses looking for responsible partners.Furthermore, {company name} takes pride in its team of highly skilled and experienced professionals who are dedicated to providing top-notch customer service. The company's engineers and technicians work closely with clients to understand their specific requirements and deliver tailored solutions that meet their exact needs. This personalized approach has been instrumental in establishing long-lasting relationships with clients and has positioned {company name} as a preferred PCB printing and assembly partner.In addition to its core services, {company name} also offers value-added services such as design consulting, testing, and prototyping. This comprehensive suite of services allows clients to entrust their entire PCB production process to {company name}, streamlining their operations and saving valuable time and resources.As the demand for electronics continues to grow, the need for reliable and efficient PCB printing and assembly services will only increase. {Company name} is well-positioned to lead the way in meeting this demand, thanks to its unwavering commitment to quality, innovation, and customer satisfaction. With a vision to revolutionize the electronic industry, {company name} is set to continue making waves in the world of PCB printing and assembly for years to come.

How to Prototype and Manufacture PCBs for Your Next Project

[Company Name], a leading manufacturer of electronic components and PCB (Printed Circuit Board) prototypes, has announced the launch of their latest product, the Prototyp PCB. This cutting-edge PCB prototype offers innovative features and advanced technology that set it apart from other products on the market.The Prototyp PCB is designed to meet the diverse needs of electronic engineers, hobbyists, and businesses looking to develop new electronic products. With its high-quality materials and precise manufacturing process, the Prototyp PCB ensures reliable performance and durability. The product is also known for its fast turnaround time, making it ideal for prototyping and testing new electronic designs.One of the key features of the Prototyp PCB is its versatility. The product supports a wide range of applications, including consumer electronics, automotive systems, medical devices, industrial equipment, and more. This flexibility makes it an excellent choice for engineers and designers working on various projects in different industries.In addition to its versatility, the Prototyp PCB offers excellent performance and functionality. The product is engineered to deliver high-speed data processing, low power consumption, and strong signal integrity, ensuring that electronic devices built with this PCB prototype will perform efficiently and reliably.[Company Name] has a proven track record of delivering high-quality electronic components and PCB prototypes to its customers. The company's team of expert engineers and technicians are dedicated to providing top-notch products and exceptional customer service. With state-of-the-art facilities and advanced manufacturing capabilities, [Company Name] is able to produce the Prototyp PCB with strict quality control measures in place, ensuring that each prototype meets the highest standards of excellence.The launch of the Prototyp PCB demonstrates [Company Name]'s commitment to innovation and continuous improvement. The company is dedicated to staying at the forefront of technology and offering cutting-edge solutions to meet the evolving needs of the electronics industry. By investing in research and development, [Company Name] is able to develop products like the Prototyp PCB that push the boundaries of what is possible in electronic design and manufacturing.Customers who choose the Prototyp PCB can expect to benefit from its high performance, reliability, and cost-effectiveness. The product's competitive pricing and quick turnaround time make it a practical choice for businesses and individuals looking to bring their electronic designs to life. With the Prototyp PCB, customers can save time and money without compromising on quality.As the electronics industry continues to evolve, [Company Name] remains committed to providing innovative solutions that empower engineers, designers, and businesses to bring their electronic innovations to market. The Prototyp PCB is the latest example of [Company Name]'s dedication to supporting the success of its customers and shaping the future of electronic design and manufacturing.In conclusion, the launch of the Prototyp PCB represents a significant milestone for [Company Name] and the electronics industry as a whole. The product's advanced features, versatile applications, and reliable performance make it an exceptional choice for anyone looking to prototype and test electronic designs. With [Company Name]'s commitment to quality and innovation, the Prototyp PCB is set to make a lasting impact on the electronic industry and empower customers to achieve their electronic design goals.

Top 5 Tips for Efficiently Assembling a Product

Assembly Of Product, a leading company in the field of manufacturing and assembly services, has recently announced the launch of its new state-of-the-art facility. This facility is specifically designed to cater to the growing demands of the assembly of a wide range of products, from consumer electronics to industrial machinery.With over 20 years of experience in the industry, Assembly Of Product has established itself as a trusted partner for businesses looking for high-quality, cost-effective assembly solutions. The company's commitment to excellence and innovation has made it a preferred choice for clients across various industries.The new facility, located in a strategic location, is equipped with advanced machinery and technology to streamline the assembly process and ensure precision and efficiency. With a focus on automation and robotics, Assembly Of Product aims to enhance productivity and reduce production lead times for its clients.In addition to its cutting-edge infrastructure, the facility is also designed to meet the highest standards of safety and environmental regulations. Assembly Of Product understands the importance of sustainability and is dedicated to minimizing its environmental impact through responsible manufacturing practices.The company's skilled and experienced workforce is another key asset that sets it apart in the industry. With a team of highly trained technicians and engineers, Assembly Of Product has the expertise to handle complex assembly projects with precision and attention to detail."We are excited to announce the opening of our new facility, which marks a significant milestone in our journey," said [CEO's Name], CEO of Assembly Of Product. "This expansion is a testament to our commitment to meeting the evolving needs of our clients and delivering exceptional assembly services that exceed their expectations."Assembly Of Product's dedication to customer satisfaction and continuous improvement has earned it a strong reputation in the market. The company has built long-lasting partnerships with clients who rely on its expertise to bring their products to market with speed and efficiency.The new facility is expected to further strengthen Assembly Of Product's position as a leader in the assembly services industry. With increased capacity and capabilities, the company is well-equipped to take on larger and more complex projects, catering to the diverse needs of its expanding client base.In line with its goal to be a one-stop solution for assembly needs, Assembly Of Product offers a comprehensive range of services, including prototype assembly, production assembly, testing, and packaging. The company's flexibility and agility allow it to tailor its services to meet the specific requirements of each client, regardless of the size or scope of the project.As Assembly Of Product continues to grow and evolve, it remains committed to upholding its values of integrity, innovation, and excellence. The company's dedication to quality and customer satisfaction positions it as a reliable partner for businesses seeking top-notch assembly services.With the opening of its new facility, Assembly Of Product is poised to embark on an exciting new chapter of growth and success. The company's unwavering commitment to pushing the boundaries of assembly technology and delivering superior solutions sets it apart as a leader in its field.

Efficient SMT Assembly Process: Streamlining Production for Optimal Results

Smt Assembly Process Revolutionizes Electronics Manufacturing IndustryIn an industry that is constantly evolving, companies are always seeking new ways to improve their manufacturing processes to stay ahead of the competition. One such company, based in {}, has recently introduced an innovative method called Surface Mount Technology (SMT) assembly process. This groundbreaking technology is set to revolutionize the electronics manufacturing industry.With the SMT assembly process, components are mounted directly onto the surface of a printed circuit board (PCB). This method eliminates the need for through-hole technology, where components are mounted by inserting leads into drilled holes on the board. Instead, SMT components are soldered onto the board using specialized machines, which saves production time and reduces costs.This new process has caught the attention of several companies in the electronics manufacturing industry due to its numerous advantages. One major benefit is the increased precision and accuracy achieved through SMT assembly. The components are placed precisely in predetermined locations, ensuring the reliability and functionality of the final product. This level of precision was previously difficult to achieve with through-hole technology.Furthermore, the SMT assembly process allows for miniaturization of electronic devices. As SMT components are smaller than their through-hole counterparts, companies can design and manufacture smaller, more compact electronic products. This is especially important in industries such as consumer electronics and medical devices, where portability and size are significant factors.Moreover, the SMT assembly process enables a higher degree of automation in production. By utilizing specialized machines, companies can streamline their manufacturing processes and increase production capacity. This automation not only improves efficiency but also reduces the potential for human error, leading to higher quality products.The environmental impact of electronic manufacturing is another critical consideration in today's world. Fortunately, the SMT assembly process is more environmentally friendly compared to through-hole technology. SMT components consume fewer materials, generate less waste, and use lead-free solders. This reduction in waste and hazardous materials contributes to a greener manufacturing process, aligning with global environmental standards.With numerous advantages in speed, precision, miniaturization, automation, and environmental impact, it's no wonder that more and more companies are adopting the SMT assembly process. One such company leading the way in implementing this revolutionary method is {}. Combining cutting-edge technology with their deep industry experience, they have successfully transformed the manufacturing process for electronics.{} is committed to providing the highest quality SMT assembly services to their clients. They understand the importance of staying at the forefront of technology in a rapidly evolving industry. With state-of-the-art equipment and a team of skilled professionals, they ensure that every product manufactured using the SMT assembly process meets the highest standards of quality and reliability.The company's dedication to customer satisfaction is unparalleled. They work closely with their clients to understand their unique requirements and provide tailored solutions that meet their specific needs. From component sourcing and PCB design to assembly and testing, {} offers a comprehensive range of services, all utilizing the innovative SMT assembly process.As the electronics manufacturing industry continues to grow and evolve, adopting cutting-edge technologies like the SMT assembly process is vital for remaining competitive. With its numerous advantages, this revolutionary method is set to transform the industry, enabling companies to produce higher quality, more compact, and environmentally friendly electronic devices.In a world where technology is advancing at an unprecedented pace, companies must adapt and embrace innovation to stay ahead. With the introduction of the SMT assembly process, {} is leading the charge in revolutionizing the electronics manufacturing industry, paving the way for a more efficient, precise, and sustainable future.

Efficient Smt Pcb Assembly Process: Everything You Need to Know

Smt Pcb Assembly Process Improves Efficiency and Quality for {Company}{Company} is a leading provider of electronic manufacturing services, specializing in Smt Pcb assembly. The company has recently invested in new equipment and technology to enhance its assembly process, aiming to improve efficiency and quality for its clients.The Smt Pcb assembly process is a crucial step in electronic manufacturing, as it involves placing and soldering surface mount components onto printed circuit boards. This process requires precision and accuracy to ensure that the final product meets the highest quality standards.{Company} has always been dedicated to staying at the forefront of technological advancements in electronic manufacturing. With the recent investment in new Smt Pcb assembly equipment, the company has taken its commitment to excellence to the next level.One of the key improvements in the new Smt Pcb assembly process is the use of advanced pick-and-place machines. These machines are equipped with state-of-the-art vision systems and robotics, allowing for faster and more accurate placement of components onto the circuit boards. This upgrade greatly enhances the efficiency of the assembly process, leading to shorter lead times for clients without compromising on quality.Furthermore, {Company} has implemented advanced soldering techniques to ensure the reliability and durability of the assembled Pcb boards. The company uses advanced reflow ovens and selective soldering equipment to achieve optimal solder joints, minimizing the risk of defects and ensuring the long-term performance of the electronic devices.In addition to equipment upgrades, {Company} has also focused on enhancing its quality control procedures in the Smt Pcb assembly process. The company has implemented rigorous inspection and testing protocols to detect and address any potential issues early in the assembly process, preventing defects and ensuring the highest quality of the final products.The investment in the Smt Pcb assembly process aligns with {Company}'s mission to provide its clients with the best possible solutions for their electronic manufacturing needs. The company understands the importance of delivering products that meet the highest quality standards, and the enhanced assembly process is a testament to its dedication to excellence.Clients of {Company} can expect to benefit from the improvements in the Smt Pcb assembly process, as they will experience faster turnarounds, higher quality, and more reliable electronic products. The company is confident that the upgrades will further solidify its position as a trusted partner in the electronic manufacturing industry.The investment in the Smt Pcb assembly process is just one example of {Company}'s continuous efforts to innovate and improve its services. With a team of skilled professionals and a strong focus on technology and quality, the company remains committed to exceeding the expectations of its clients and setting new standards in electronic manufacturing.As the demand for high-quality electronic products continues to grow, {Company} is well-positioned to meet the needs of its clients and adapt to the ever-changing market dynamics. The company's dedication to investing in the latest technology and process improvements ensures that it remains a leader in the electronic manufacturing industry.In conclusion, the recent investment in the Smt Pcb assembly process at {Company} has brought about significant improvements in efficiency and quality. With advanced equipment and technology, the company has strengthened its capabilities and positioned itself as a reliable partner for electronic manufacturing needs. The enhancements in the assembly process are a testament to {Company}'s commitment to excellence and its dedication to exceeding client expectations.