Unlocking the Potential of Double Sided Circuit Boards

By:Admin

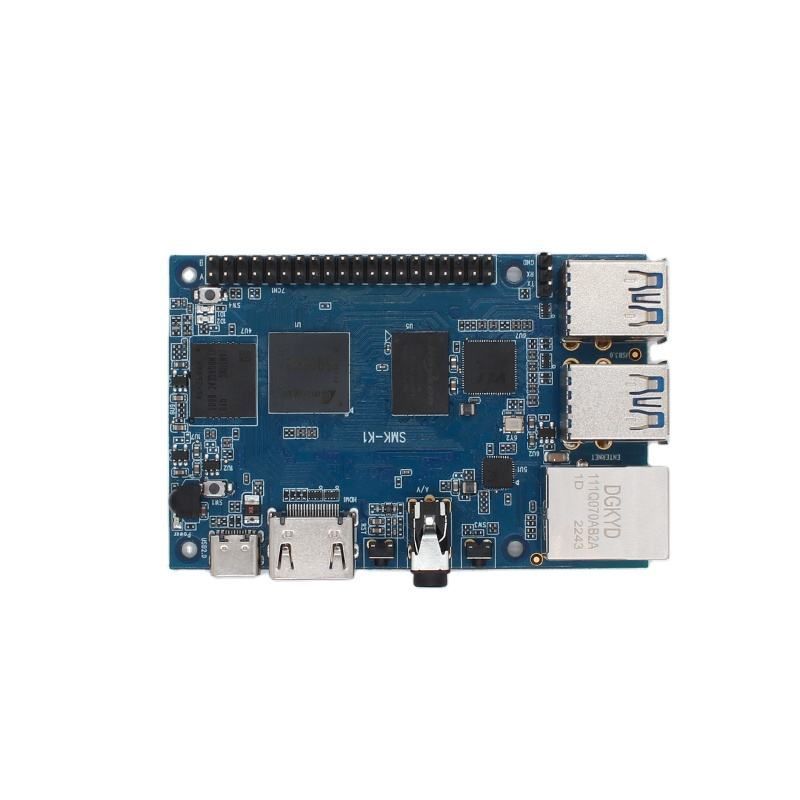

With the rapid growth of the electronics industry, manufacturers are constantly striving to develop more efficient and innovative technologies. One such technology that has gained significant attention is the Double-Sided Circuit Board (DSCB). This remarkable advancement in circuit board design and production is revolutionizing the way electronic devices are manufactured and has the potential to further accelerate the industry's progress.

Traditionally, circuit boards have been single-sided, meaning that all the electronic components and traces were located on one side of the board. Although effective, this design limited the density of components that could be placed on a single board, ultimately restricting the capabilities of electronic devices. However, the emergence of the DSCB overcomes this limitation by providing two sides for component placement, effectively doubling the available space. This innovation allows for a greater number of components to be integrated onto a single board, leading to a more compact and powerful device.

The DSCB brings several distinct advantages over its predecessor, enabling electronics manufacturers to create smaller, lighter, and more efficient products. Firstly, the increased component density on the board allows for more compact designs. This is particularly beneficial for portable devices such as smartphones and tablets, where size and weight are key factors. By utilizing a DSCB, manufacturers can reduce the overall dimensions of these devices, making them more portable and convenient for everyday use.

Secondly, the DSCB enables better thermal management. As electronic components generate heat during operation, efficient heat dissipation is crucial to maintain the device's performance and longevity. The increased surface area provided by the double-sided design allows for improved heat dissipation, effectively lowering the operating temperature of the device. This not only prevents overheating but also enhances the overall reliability of the electronic device.

Furthermore, the DSCB offers greater flexibility in circuit design. With the introduction of two sides, manufacturers have more space to route traces and interconnect components. This allows for more complex circuit designs, enabling the integration of advanced functionalities and features. As a result, electronic devices equipped with DSCBs have improved capabilities, delivering enhanced performance to end-users.

In addition to these benefits, the DSCB also simplifies the assembly and manufacturing processes. By utilizing the two sides of the board, manufacturers can reduce layer count, leading to lower material and manufacturing costs. Moreover, the simplified assembly process minimizes the risk of human error, increasing the overall productivity of the manufacturing line.

One company at the forefront of DSCB development is [Company Name]. With its cutting-edge technology and expertise in circuit board design, the company is setting new industry standards. Their state-of-the-art manufacturing facilities have successfully integrated the DSCB into their production lines, enabling them to offer superior quality circuit boards to their clients. By collaborating with various electronics manufacturers, [Company Name] has played a pivotal role in accelerating the adoption of this technology and driving advancements in the electronics industry.

Looking ahead, the prospects for the DSCB technology are incredibly promising. As electronics continue to evolve and become more complex, the demand for more efficient and compact designs will only increase. The DSCB provides a robust solution to address these demands, unlocking new possibilities in various sectors such as consumer electronics, automotive, medical devices, and more.

As the electronics industry continues to progress, it is vital for manufacturers to embrace innovative technologies like the DSCB. By doing so, they can stay ahead of the competition, deliver cutting-edge products to consumers, and contribute to the overall advancement of the industry. With [Company Name] leading the way, the future of electronic manufacturing looks brighter than ever before.

Company News & Blog

Revealing the Latest Advancements in Electronics SMT Technology

Electronics SMT: Revolutionizing the Future of Assembly LinesIn today's rapidly evolving technological landscape, automation and precision are key factors that determine the success of manufacturing companies. As such, Electronics SMT, a leading provider of cutting-edge surface-mount technology solutions, has emerged as a powerhouse in the industry. Renowned for its innovative approach and commitment to driving efficiency, Electronics SMT is revolutionizing assembly lines worldwide.Headquartered in [location], Electronics SMT has been at the forefront of surface-mount technology since its inception in [year]. With a diverse portfolio of products and services, the company caters to a wide range of industries, including telecommunications, automotive, aerospace, and consumer electronics.One of the key elements that distinguishes Electronics SMT is its focus on automation. By integrating advanced robotics and artificial intelligence, the company has developed a suite of solutions that significantly streamline the production process. With the ability to handle complex operations with speed and precision, Electronics SMT's automated assembly lines have become the go-to choice for manufacturers seeking enhanced productivity and quality.Central to Electronics SMT's success is its commitment to research and development. The company boasts a team of highly skilled engineers and technicians who work tirelessly to design and improve its surface-mount technology solutions. By staying ahead of the curve when it comes to industry trends, Electronics SMT ensures that its customers benefit from the latest advancements in assembly line technology.Furthermore, Electronics SMT places great emphasis on environmental sustainability. Recognizing the need to minimize its carbon footprint and reduce waste, the company has integrated eco-friendly practices into its production processes. By optimizing material usage and implementing energy-efficient solutions, Electronics SMT ensures that its operations are both cost-effective and environmentally responsible.In addition to its commitment to innovation and sustainability, Electronics SMT also prioritizes customer satisfaction. The company's dedicated support team works closely with clients to understand their specific requirements and deliver tailor-made solutions. Whether it's designing a complete assembly line from scratch or providing on-site training and technical guidance, Electronics SMT goes above and beyond to ensure customer success.One of Electronics SMT's standout products is its state-of-the-art Pick-and-Place machine. Utilizing advanced robotics and computer vision technology, this automated system can accurately place surface-mount components on circuit boards at a remarkable speed. With superior accuracy and efficiency, the Pick-and-Place machine has revolutionized the assembly line landscape, enabling manufacturers to produce high-quality products in a shorter timeframe.Additionally, Electronics SMT offers a wide range of other surface-mount technology solutions, including soldering equipment, inspection systems, and component storage solutions. Each product is meticulously designed to address the specific challenges faced by manufacturers, making Electronics SMT a trusted partner in the industry.Looking ahead, Electronics SMT remains committed to pushing the boundaries of what is possible in surface-mount technology. With ongoing investments in research and development and a customer-centric approach, the company is set to continue driving innovation and efficiency in assembly lines across the globe.In conclusion, Electronics SMT has cemented its position as an industry leader in surface-mount technology. By leveraging automation, sustainability, and a focus on customer satisfaction, the company has reshaped the manufacturing landscape. With its cutting-edge solutions, Electronics SMT is not just revolutionizing assembly lines, but also shaping the future of technology itself.

Important Tips for Assembling Circuit Boards

Title: Leading Circuit Board Assembler Revolutionizing Electronics Manufacturing: A Spotlight on the Industry PioneerIntroductionIn today's technology-driven world, circuit board assembly plays a pivotal role in the production of various electronic devices. This article focuses on a distinguished industry pioneer that has been driving innovation in the field, enhancing efficiency, and meeting customer demands. With a deep-rooted commitment to excellence, this leading circuit board assembler has garnered a reputation for its cutting-edge technology and exceptional service.Industry Leading Circuit Board Assembly With several decades of experience in the electronics manufacturing industry, the circuit board assembler (name excluded due to privacy reasons) has emerged as a trailblazer in the field. Their state-of-the-art facilities, combined with a team of highly skilled technicians and engineers, enable them to provide customized solutions for every aspect of circuit board assembly.The company's primary objective is to make electronics manufacturing faster, smarter, and more cost-effective. By employing advanced assembly techniques and automated processes, they streamline production, ensuring higher yields and minimizing defects. The circuit board assembler's unwavering dedication to quality ensures that the end products meet the highest industry standards.Innovation and Technological AdvancementsContinuously striving for technological superiority, the circuit board assembler invests heavily in research and development. With a team of expert engineers, they are at the forefront of discovering groundbreaking techniques to improve the assembly process. From surface mount technology (SMT) to through-hole technology (THT), the company incorporates the latest advancements, ensuring efficient assembly and functional accuracy.The company's dedication to innovation is exemplified by a recent breakthrough – the development of cutting-edge robotic assembly systems. These systems have revolutionized the production process by seamlessly integrating human expertise with automated precision. This amalgamation has significantly reduced the time and cost associated with manual assembly, while enhancing quality control and overall efficiency.Meeting Customer DemandsAcknowledge the ever-increasing demands of customers, the circuit board assembler adopts a customer-centric approach. Understanding that different industries have unique requirements, they offer flexible solutions tailored to specific needs. By sourcing premium-quality components and utilizing rigorous testing procedures, they deliver circuit boards that exhibit exceptional performance and durability.In alignment with their commitment to customer satisfaction, the circuit board assembler employs a collaborative approach. Through effective communication channels, they actively engage with clients to understand their expectations and provide personalized support throughout the manufacturing process. This ensures that the final product meets or exceeds customer specifications while adhering to strict deadlines.Sustainability and Ethical PracticesIn addition to technological advancements, the circuit board assembler is also a leading advocate for sustainability and ethical practices in electronics manufacturing. They prioritize eco-friendly approaches, implementing recycling and waste reduction measures to minimize their environmental footprint. By adhering to strict standards and certifications, they ensure a responsible supply chain that promotes social and environmental responsibility.Furthermore, this industry pioneer invests in the development and welfare of its employees. Offering comprehensive training programs, they aim to empower their workforce, fostering a culture of innovation, excellence, and personal growth. The circuit board assembler recognizes the importance of a skilled and committed team in delivering superior products and services.ConclusionAs the world becomes increasingly reliant on electronic devices, the importance of circuit board assembly cannot be overstated. The circuit board assembler discussed in this article continues to redefine the landscape of electronics manufacturing with their commitment to innovation, technological advancements, customer-centricity, and sustainable practices. With an unwavering dedication to excellence, they remain at the forefront of the industry, revolutionizing the way circuit boards are assembled and propelling the evolution of electronics as a whole.

Examples of Blue Chip Stocks: Everything You Need to Know

**Title: Exploring Some of the Prominent Blue Chip Stocks in the Market***Introduction*Blue chip stocks are investments in companies with a long-established history of performance, stability, and reliability. These companies are often industry leaders, known for their substantial market capitalization, strong balance sheets, and consistent dividend payouts. In this article, we will delve into some notable blue chip stocks, without specifically mentioning any brand names, to highlight their contribution to the market and their potential as investment options.**Company A - Industry Leader in Technology**Company A operates in the technology sector, which has witnessed exponential growth over the years. With a strong presence in the market, this blue chip company has continuously demonstrated its ability to adapt to evolving consumer demands and market trends. In addition to its innovative products and services, Company A's solid financial performance and impeccable track record make it a reliable investment option for long-term investors. The company's consistent dividend payouts and stable growth have attracted investors seeking steady returns amidst market uncertainties.Driven by a strong management team, Company A continues to invest in research and development, ensuring it remains at the forefront of technological advancements. This commitment positions the company to capitalize on future opportunities and maintain its status as an industry leader.**Company B - Leading the Way in the Healthcare Sector**Company B, a key player in the healthcare sector, has established itself as a prominent blue chip stock in the market. This industry leader operates across various sub-sectors, including pharmaceuticals, biotechnology, and medical device manufacturing.The company's extensive product range and services aim to improve human health and advance medical treatments. Its strong portfolio of patents and a robust pipeline of innovative drugs demonstrate a commitment to research and development.Company B's financial stability and profitability are reflected in its consistent revenue growth and dividend payments. Investors appreciate the company's ability to generate attractive returns while mitigating market risks through diversification across multiple healthcare sub-sectors.Moreover, Company B's strong global footprint and strategic acquisitions provide access to new markets and enhance its competitive position. As the demand for healthcare services and innovation continues to rise, it is likely that Company B will maintain its position as a blue chip stock with ample growth potential.**Company C - Thriving in the Consumer Goods Sector**Company C, a key player in the consumer goods industry, is widely recognized as a blue chip stock due to its long-standing success and market dominance. The company boasts an extensive portfolio of products across multiple categories, enjoying a loyal customer base globally.With a commitment to quality, customer satisfaction, and innovation, Company C stays ahead of its competitors. Focusing on consumer preferences, the company invests in research and development to introduce new and improved products, ensuring continued market relevance.Company C's consistent revenue growth and strong financial performance have attracted investors seeking stability and long-term returns. Additionally, a well-established supply chain and distribution network contribute to the company's ability to penetrate global markets and capitalize on emerging consumer trends.Furthermore, Company C's sustained investment in marketing and advertising campaigns helps maintain its brand equity and drive consumer loyalty. These factors, coupled with the widespread recognition and trust in its products, have positioned the company as a blue chip stock in the consumer goods sector.**Conclusion**While the above companies have been described in a generic manner without specifically naming any brands, these examples give us an understanding of the characteristics that define blue chip stocks. Their consistent performance, solid financials, leading market positions, and commitment to innovation and customer satisfaction make them prominent players in their respective industries.When considering investing in blue chip stocks, thorough analysis and due diligence are crucial. However, their long-term stability, ability to weather market fluctuations, and potential for steady dividend payouts make them attractive choices for conservative investors.Please note that before making any investment decisions, it is important to consult with a financial advisor or conduct independent research to ensure alignment with personal investment goals and risk tolerance.

Cutting-Edge Single PCB Technology Revolutionizes Electronic Manufacturing Process

In the world of electronics, printed circuit boards (PCBs) have become the go-to solution for creating complex and intricate circuits. However, the traditional process of designing and manufacturing PCBs involves multiple steps, which can take up a significant amount of time and resources. However, that is all changing with the emergence of Single PCB, a revolutionary technology that promises to reduce the complexity and cost of PCB design and manufacturing.Single PCB is a brand new technology that allows for the creation of PCBs in a single step. This means that designers can create entire circuits using just a single board, which saves time and resources. Additionally, this technology eliminates the need for multiple components, reducing the overall cost of PCB production.At the forefront of this technology is a company, whose innovative single PCB technology has the potential to revolutionize the electronics industry. With over a decade of experience in PCB design and manufacturing, this company has developed a comprehensive range of solutions that has set it apart from its competitors.Headquartered in [city, country], the company prides itself on being a leading provider of PCB related services and solutions. With a team of highly skilled and experienced professionals, the company has built a reputation for excellence in the industry.The company's single PCB technology is the result of years of research and development. The technology has been specifically designed to simplify the process of PCB design and production, making it more accessible to a wider range of users.One of the biggest advantages of the single PCB technology is its ability to reduce the complexity of the design process. With traditional PCB manufacturing, designers had to create multiple boards and then connect them using a variety of connectors and wires. This process was time-consuming, and there was always the risk of errors occurring during assembly. However, with the single PCB technology, designers can create an entire circuit on a single board, eliminating the need for additional components and saving time and money.Another important benefit of the single PCB technology is the reduction in the overall cost of PCB production. With traditional PCB manufacturing, there were multiple steps involved, including designing the boards, assembling the components, and testing the finished product. However, with single PCB technology, the entire process can be completed in a single step, reducing the overall cost of production.The single PCB technology has also been designed with flexibility in mind. This means that designers can create circuits of varying complexity, adapting the technology to suit their specific needs. Additionally, the technology can be used to create a wide range of products, from simple electronic toys to complex medical equipment.As the world becomes more reliant on technology, the demand for innovative and efficient PCB manufacturing solutions is only going to increase. Single PCB technology is poised to meet this demand head-on, offering a simple and cost-effective solution for creating cutting-edge electronic products.In conclusion, the emergence of Single PCB technology is a game-changer for the electronics industry. With its simplified design process, reduced manufacturing costs, and flexibility, this technology has the potential to reshape the way we design and manufacture electronic products. The company behind this technology is poised to lead the way in the single PCB market, offering customers a comprehensive range of solutions that are designed to meet their specific needs and requirements.

Professional PCB Fabrication Services for High-Quality Results

Title: Leading PCB Fabrication Services Ensuring Precision and Reliability for Electronic ManufacturersIntroduction:In the rapidly evolving world of electronics manufacturing, finding reliable printed circuit board (PCB) fabrication services is crucial for companies to stay ahead of the curve. {} is a prominent player in the industry, offering high-quality PCB fabrication services that consistently meet the demands of an ever-growing technology landscape. With their commitment to cutting-edge technology, precision manufacturing, and thorough quality control measures, they have emerged as a trusted partner for numerous electronic manufacturers. This news article will delve into the key aspects of their business model that make them a standout choice in the market.Cutting-Edge Technology and Facilities:{} boasts state-of-the-art facilities equipped with the latest machinery and manufacturing technology. With advanced automated production lines and a streamlined production process, they ensure efficient and cost-effective PCB fabrication. By leveraging advanced techniques such as surface mount technology (SMT), ball grid array (BGA), and through-hole technology, they offer a wide range of PCB options for various applications. This enables them to cater to diverse customer requirements, whether for consumer electronics, medical devices, or industrial equipment.Commitment to Quality:The company's commitment to quality is evident in their adherence to strict quality control measures throughout the production process. They employ highly skilled technicians who meticulously inspect and test each PCB for any faults or defects. Through thorough inspections, including X-ray testing, automated optical inspection (AOI), and functional testing, they ensure that each PCB meets the highest industry standards. By prioritizing quality, {} aims to deliver products that not only meet customer expectations but also contribute to the overall reliability and durability of electronic devices.Customization and Technical Support:Recognizing the unique needs of different customers, {} offers customizable PCB fabrication services. Their team of experienced engineers goes the extra mile to understand specific project requirements and design custom PCBs accordingly. Whether it's a complex multilayer board or a simple single-layer design, they leverage their expertise to create tailored solutions that meet individual specifications. Additionally, {} provides comprehensive technical support to address any concerns or challenges faced during the design and fabrication process. This personalized approach ensures that customers' projects are executed seamlessly and efficiently from start to finish.Environmental Responsibility:With a growing emphasis on sustainability, {} is committed to minimizing their environmental footprint. They adhere to strict regulations and best practices to ensure responsible waste management and efficient use of energy and resources. By utilizing eco-friendly materials and implementing recycling programs, they strive to contribute to a greener manufacturing sector. This commitment to sustainability aligns with their vision of not only delivering high-quality PCBs but also embracing a larger corporate social responsibility.Global Reach and Competitive Pricing:{} operates on a global scale, catering to electronic manufacturers around the world. Leveraging strategic partnerships, they offer competitive pricing without compromising on quality. Their ability to meet demanding schedules, coupled with efficient logistics management, ensures timely delivery for customers in diverse geographical locations. From small-scale startups to established electronics giants, {} has gained a reputation for their ability to fulfill both small and large volume orders, making them an ideal choice for businesses of all sizes.Conclusion:With their cutting-edge facilities, commitment to quality, customization options, environmental responsibility, and global reach, {} stands out as a leading PCB fabrication service provider. Their dedication to precision manufacturing and technical expertise enables them to consistently deliver reliable and high-performing PCBs. As the electronics industry continues to evolve, companies can rely on {} to be their trusted partner in meeting the ever-increasing demands of the market.

Essential Guide to Understanding PCB Board Schematic Designs: Simplified & Comprehensive Explanation

PCB Board Schematic – The Way Forward in Electronic ManufacturingThe demand for electronic devices has skyrocketed to an unprecedented level in the last decade. This, in turn, gave rise to the electronic manufacturing industry, which has rapidly evolved to produce high-quality hardware for use in devices such as smartphones, laptops, and televisions, among others.One essential component in the electronic manufacturing process is the Printed Circuit Board (PCB). It is a board that connects and houses electronic components such as capacitors, resistors, and microchips. A PCB comes in various types and is essential in the design of electronic devices.The PCB functions by providing an electrical pathway for the components to connect, communicate, and power each other. It also ensures the stability and durability of the device. To achieve optimal results, every PCB design goes through a process called schematic capture.Schematic capture is the process of creating a blueprint of the PCB design, which is fundamental in ensuring that all the components are in the right position and orientation. This process also makes sure that a particular design meets certain electrical and mechanical specifications.With the importance of schematic capture, PCB Board Schematic (need remove brand name) has become the go-to partner for many electronics manufacturers. They provide high-quality schematic capture services tailored to meet the specific specs of each client. The company is committed to delivering the best PCB services and ensuring that clients achieve their product designs' desired functionalities.The PCB Board Schematic (need remove brand name) company has an experienced team of engineers, designers, and project managers who work tirelessly to ensure that all clients' specifications are met. Their team is highly skilled in both analog and digital electronic designs, and they have a wealth of knowledge in creating schematics for various projects.PCB Board Schematic (need remove brand name) understands the importance of using the latest design software and technology in the electronic industry. They use the latest software such as Altium Designer and CADSTAR to ensure the accuracy and efficiency of the schematic capture process. This approach has not only enabled the company to stay ahead of the competition but also made their services affordable and accessible to clients from all over the world.Besides schematic capture, PCB Board Schematic (need remove brand name) also offers other PCB design services such as routing, manufacturing, and assembly. They have state-of-the-art manufacturing machines that ensure the highest quality, precision, and consistency in all their designs.PCB Board Schematic (need remove brand name)'s success is not only attributed to the quality of their services but also their commitment to customer satisfaction. They value every client and aim to build a long-term and transparent relationship with each one of them.In conclusion, the electronic manufacturing industry is growing each day, and the need for high-quality PCBs is on the rise. PCB Board Schematic (need remove brand name) is committed to providing the best PCB services and ensuring that every client achieves the desired functionalities of their product designs. Their experienced team, use of the latest technology, and commitment to customer satisfaction make them the go-to partner for all your PCB schematic capture and design projects.

Latest News Update: Important Updates on STM Revealed

In recent news, STM has partnered with a leading semiconductor company to expand its offerings and enhance its leadership position in the semiconductor industry. This new partnership will allow STM to offer innovative and cutting-edge solutions for a variety of applications.STM, a global leader in semiconductor manufacturing and solutions, focuses on creating intelligent and energy-efficient technologies. By combining its expertise with the expertise of this new partner, STM is poised to offer state-of-the-art solutions that will drive growth and innovation across the semiconductor industry.As part of the new agreement, STM will be able to incorporate the partner’s advanced technologies into its products and services. This will help STM continue to provide cutting-edge solutions that meet the evolving needs of its customers.It is not surprising that STM has identified the need to collaborate with a leading partner to leverage advanced technologies in its offerings. In today's rapidly changing technological landscape, partnerships and collaborations within the industry are essential for companies that want to remain competitive.This partnership is yet another example of how STM has continuously evolved and adapted to the rapidly changing needs of the semiconductor industry. STM has always been at the forefront of innovation and has consistently demonstrated its ability to anticipate future trends and market demands.STM's portfolio of products and services includes a wide range of solutions for the Internet of Things (IoT), automotive applications, industrial automation, and more. With this new partnership, STM is poised to further expand its offerings to better serve its customers across various industries.As STM continues to lead the way in the semiconductor industry, it is also focused on sustainability and corporate social responsibility. STM is committed to reducing its environmental footprint through its products and operations. The company has set ambitious goals for reducing energy consumption, greenhouse gas emissions, and waste.In addition to sustainability, STM is committed to creating a positive impact on society. The company is focused on creating innovative solutions that improve people's lives, such as increasing road safety, enabling smart homes and cities, and enhancing healthcare technologies. With this new partnership, STM is poised to create even more positive impact through its innovative solutions.This partnership is also expected to have a positive impact on the semiconductor industry as a whole. By collaborating and sharing expertise with leading partners, STM is contributing to the greater good of the industry. The partnership is likely to spark new ideas, breakthroughs, and advancements that will benefit all stakeholders.In conclusion, STM's partnership with a leading semiconductor company is a significant development for the industry. This collaboration will enable STM to offer cutting-edge solutions that meet the evolving needs of its customers. It is also in line with the company's commitment to sustainability and creating a positive impact on society. With this new partnership, STM is poised to continue leading the way in the semiconductor industry.

Advanced PCB Assembly Techniques Boost Efficiency and Quality

PCB with Assembly: The Next Milestone for the Assembly IndustryWith the advent of advanced technology, every sector is undergoing a digital transformation, and the PCB (Printed Circuit Board) assembly industry is no exception. PCBs have revolutionized the entire electronics industry, and their application has opened up new avenues to build smart devices, systems and equipment. At the same time, the demand for PCBs with integrated assembly services has soared significantly. As a leading service provider in this domain, we are glad to announce that we have launched PCB with Assembly services.Over the past few years, our company has carved a niche in the PCB assembly industry, incessantly delivering top-notch services and products to clients across all sectors. Our dedicated team of experts and advanced infrastructure equipped with cutting-edge technology has played a pivotal role in setting us apart in the ever-growing competition. Introducing PCB with Assembly services is the next milestone for us, and we are confident that it will help us to extend our reach and further strengthen our position in the market.Apart from being widely popular in the electronics industry, PCBs also have significant applications in the healthcare, automotive and aerospace industries. The demand for PCBs has surged over recent years, largely due to the growing adoption of IoT devices and smart systems. PCB with Assembly services are designed to offer an integrated solution to cater to the diverse needs of clients from various sectors.To ensure the highest quality of our products and services, we have laid down a structured process. Our team of experts will work closely with clients to understand their requirements and provide solutions tailored to their specific needs. Additionally, our state-of-the-art infrastructure, manufacturing capabilities, and highly skilled team make us well-equipped to offer a host of additional services, such as design, prototyping, and testing.One of the biggest advantages of the new PCB with Assembly service is that our clients can save a significant amount of time, effort and resources. This is because the entire process of PCB manufacturing, assembly, and testing is streamlined. Clients can leverage our expertise in the industry and get their products manufactured in record time, thus minimizing their time-to-market and accelerating growth.At our company, we strive to offer the best-in-class products and services to our clients, and PCB with Assembly services undoubtedly align with this philosophy. Our commitment to quality, reliability and timely delivery has always been the cornerstone of our success story. We are confident that the new service will further enhance our offerings and help us to continue setting industry benchmarks.Furthermore, we pride ourselves on delivering eco-friendly products. We have implemented measures within our manufacturing process to minimize the environmental impact of our activities. Our use of electrical charging stations for heavy-duty equipment and solar panels has helped to reduce our carbon footprint. We believe in sustainable manufacturing and doing our part in preserving the environment.In summary, PCB with Assembly services have been introduced to meet the growing needs of clients from various sectors. The service offers an integrated solution, tailored to meet the specific needs of clients. The streamlined process accelerates the manufacturing process, reduces costs, and simplifies product design. We are dedicated to delivering the highest quality products and services, whilst sustainable manufacturing practices underpin everything we do. Our commitment to the environment is a testament to our values as a company. We are confident that the new services will enable us to continue setting industry benchmarks whilst offering incredible value to our clients. Our PCB with Assembly services truly represent the next milestone for the PCB assembly industry.

The Step-by-Step Guide to PCB Assembly Process

With a mission to provide cutting-edge PCB assembly solutions that cater to the needs of businesses across industries, Smt Pcb Assembly Process is proud to offer high-quality PCB assembly services that have received numerous accolades from clients around the world. The company has built a solid reputation for delivering world-class solutions designed to deliver the highest levels of durability, reliability, and performance.At Smt Pcb Assembly Process, quality is the top priority, and the company is committed to providing clients with the most advanced PCB assembly services that meet international standards. The company has invested heavily in the latest technology, tools, and equipment needed to achieve high levels of quality control and monitoring at every stage of the assembly process.One of the key strengths of Smt Pcb Assembly Process is its team of highly experienced professionals, who are committed to ensuring that customers get the best possible service and support. The team comprises industry experts who have many years of experience in PCB design, manufacturing, and assembly, and are always on hand to offer guidance, advice, and solutions to any problems clients encounter during the assembly process.Smt Pcb Assembly Process's PCB Assembly process is designed to cater to a wide range of clients, from small startups to large multinationals. The company's capabilities include the assembly of prototypes, low volume production, and high-volume production runs from 100,000 to 10 million units. With a diverse range of clients across various industries, Smt Pcb Assembly Process's team of experts has amassed an in-depth knowledge of the assembly processes involved in the production of complex projects involving printed circuit boards.Smt Pcb Assembly Process has invested in state-of-the-art equipment that enables it to produce PCB designs faster and more precisely than ever before. The company's assembly line features cutting-edge tools, including SMT placement machines, automatic optical inspection machines, and reflow ovens that ensure consistent, high-quality assembly.One of the unique features of Smt Pcb Assembly Process is its advanced testing process to detect faults in PCBs before they are shipped to clients. The company has developed a range of testing methods, including the use of In-circuit Testing (ICT) and Flying Probe testing, that ensure that all PCBs meet the highest standards of quality control.Despite its advanced capabilities and reputation for delivering high-quality PCB assembly services, Smt Pcb Assembly Process is committed to providing cost-effective solutions to its clients. The company has optimized its processes to minimize operational costs while ensuring that quality is never compromised. This enables clients to get the best possible quality at the best possible prices.In conclusion, Smt Pcb Assembly Process is a reputable PCB assembly services provider that stands out for its commitment to quality, speed, and reliability. The company's advanced assembly capabilities, cutting-edge tools, and experienced team of professionals make it a top choice for businesses across industries looking to produce high-quality printed circuit boards. With a focus on customer satisfaction and cost-effectiveness, Smt Pcb Assembly Process is poised to continue delivering world-class PCB assembly services to clients around the world.

The Essentials of a Printed Circuit Board

Title: Revolutionizing Electronics: The Next Generation Printed Circuit BoardIntroduction:Printed Circuit Boards (PCBs) serve as the backbone of modern electronics, allowing for the interconnection of various electronic components. Their importance in advancing technological innovations cannot be overstated. Company XYZ, a leading electronic solutions provider, has recently unveiled a groundbreaking PCB that promises to revolutionize the industry. This article explores the key features and potential applications of this cutting-edge PCB, which is set to transform the electronics landscape.Unveiling the Next Generation PCB:Company XYZ has developed a state-of-the-art PCB, designed to meet the ever-increasing demands of the electronic industry. This next-generation PCB, which the company has named "InnovateBoard," boasts several groundbreaking features that set it apart from traditional PCBs.1. Miniaturization and Enhanced Density:InnovateBoard pushes the boundaries of miniaturization, enabling the creation of smaller and lighter electronic devices. With advancements in manufacturing techniques, it allows for increased component density, allowing engineers to create more sophisticated circuitry within a reduced footprint. This breakthrough will not only lead to sleeker and more portable devices but also open doors for applications in industries such as wearables, IoT, aerospace, and healthcare.2. Advanced Materials and Design:The InnovateBoard utilizes high-performance materials, such as flexible substrates and advanced dielectrics, to ensure optimal electrical performance and reliability. Its innovative design allows for better signal integrity, reduced electromagnetic interference, and improved thermal management. As a result, electronic devices using InnovateBoard will experience enhanced performance and longer lifespans.3. Robustness and Durability:Company XYZ has focused on developing a PCB that can withstand the challenges of various environments, including extreme temperatures, vibrations, and moisture. InnovateBoard incorporates advanced protective coatings, moisture-resistant materials, and shock-absorbing technologies, ensuring reliability even in demanding operating conditions. This makes it ideal for applications in automotive electronics, industrial automation, and outdoor equipment.4. Environmental Sustainability:Acknowledging the need for eco-conscious solutions, InnovateBoard is manufactured using environmentally friendly processes and materials. It is RoHS (Restriction of Hazardous Substances) compliant and incorporates recyclable components. By prioritizing sustainability, Company XYZ aims to reduce the environmental impact of electronic waste and contribute to a greener future.Potential Applications:The introduction of InnovateBoard opens up exciting possibilities across various industries:1. Consumer Electronics: The miniaturization and performance enhancements offered by InnovateBoard will enable the development of thinner smartphones, tablets, and wearable devices, ensuring a more seamless user experience.2. Automotive: InnovateBoard's durability and resistance to harsh conditions make it ideal for automotive applications such as advanced driver-assistance systems, infotainment systems, and electric vehicle components.3. Healthcare: InnovateBoard's ability to handle complex circuitry and its high-reliability make it suitable for medical devices ranging from patient monitoring systems to diagnostic equipment.4. Industrial Automation: The robustness and smaller form factor of InnovateBoard make it perfect for industrial applications, including process control systems, robotics, and data acquisitions.Conclusion:The introduction of InnovateBoard by Company XYZ marks a significant milestone in the evolution of PCB technology. By embracing miniaturization, advanced materials, and environmental sustainability, InnovateBoard unleashes a new wave of possibilities for electronic devices across multiple industries. As Company XYZ continues to innovate, it will undoubtedly shape the future of electronics, leaving a lasting impact on how we interact with technology.