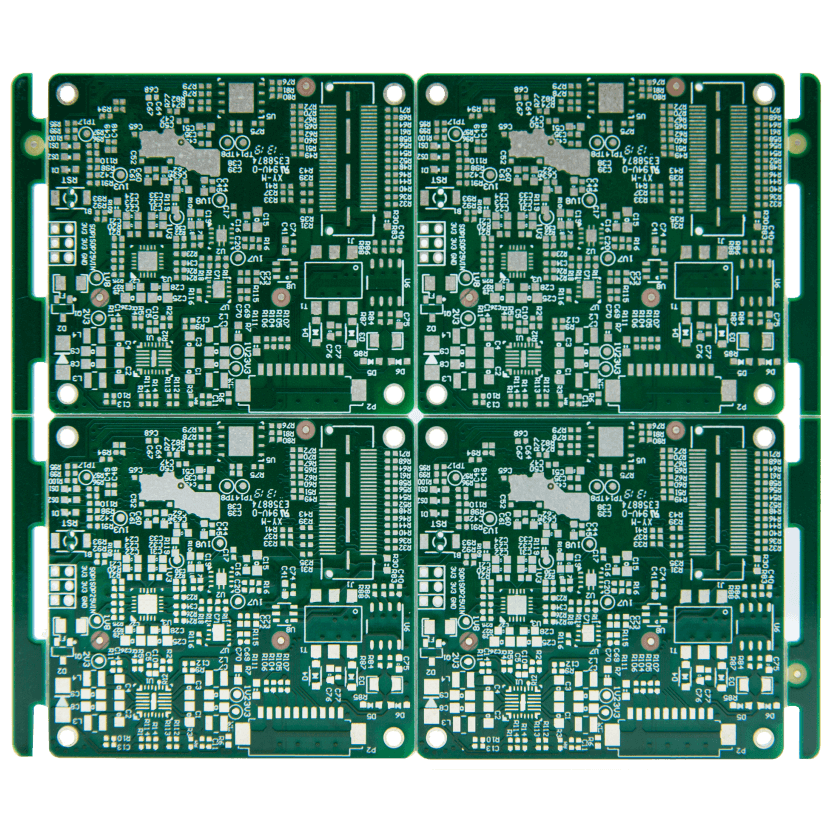

Affordable PCB Assembly Services for Your Project

By:Admin

{} specializes in providing low-cost PCB assembly services to a wide range of industries, including consumer electronics, automotive, medical devices, and more. With state-of-the-art facilities and a team of experienced engineers and technicians, {} is able to deliver high-quality PCB assembly at a fraction of the cost compared to traditional providers.

One of the key factors that set {} apart in the industry is their commitment to using the latest manufacturing technologies and equipment. This allows them to streamline the assembly process, reduce production costs, and ultimately offer low-cost PCB assembly services without sacrificing quality or reliability.

Furthermore, {} prides itself on its ability to offer tailored solutions to meet the specific needs of each customer. Whether it's a small batch production or a large-scale manufacturing project, {} has the capabilities to handle a wide range of PCB assembly requirements while keeping costs low.

In addition to low-cost PCB assembly, {} also provides value-added services such as prototyping, design for manufacturability (DFM) reviews, and testing to ensure the highest quality standards are met. This comprehensive approach to PCB assembly has earned {} a reputation as a trusted partner for companies looking to reduce manufacturing costs without compromising on the integrity of their products.

With a focus on continuous improvement and customer satisfaction, {} has positioned itself as a reliable and cost-effective solution for all PCB assembly needs. By leveraging their expertise and cutting-edge technology, {} is able to deliver high-quality PCB assembly services at a competitive price point, making them a preferred choice for companies looking to optimize their manufacturing processes and reduce expenses.

As the demand for low-cost PCB assembly continues to rise, {} remains committed to staying ahead of the curve and providing innovative solutions that meet the evolving needs of the industry. With a strong track record of delivering low-cost, high-quality PCB assembly services, {} is well-positioned to become a leader in the electronics manufacturing landscape.

In conclusion, low-cost PCB assembly services offered by {} are revolutionizing the electronics manufacturing industry by providing a cost-effective solution without compromising on quality. With their advanced capabilities, commitment to customer satisfaction, and dedication to leveraging the latest technologies, {} is set to become the go-to provider for companies seeking affordable and reliable PCB assembly services.

Company News & Blog

Understanding the Basics of DFM (Design for Manufacturability) in PCB Manufacturing

DFM in PCB (Design for Manufacturing in Printed Circuit Board) is a crucial aspect of the PCB manufacturing process. It ensures that the design of the PCB is optimized for efficient and cost-effective manufacturing. By incorporating DFM principles into the design phase, manufacturers can avoid costly errors and delays during production.{Company Name} is a leading PCB manufacturing company that specializes in producing high-quality and reliable circuit boards for various industries. With state-of-the-art facilities and a team of experienced engineers, they are committed to delivering superior PCB solutions to their customers.Recently, {Company Name} has announced that they have enhanced their DFM capabilities to further improve the quality and efficiency of their PCB manufacturing process. By investing in advanced DFM software and training their engineers on the latest DFM guidelines, {Company Name} aims to streamline their production workflow and deliver even higher quality PCBs to their customers.DFM in PCB involves several key elements, including design optimization, material selection, and process validation. By utilizing DFM software, {Company Name} can analyze the design of the PCB and identify any potential manufacturability issues, such as component placement, trace width, or spacing constraints. This allows them to make necessary adjustments to the design early in the process, reducing the risk of manufacturing errors and ensuring that the final PCB meets performance requirements.In addition, {Company Name} is also focusing on material selection as part of their DFM strategy. By carefully choosing the right materials for each PCB design, they can ensure that the final product meets the necessary performance and reliability standards. This involves considering factors such as thermal properties, signal integrity, and cost-effectiveness to achieve the best possible outcome for their customers.Furthermore, process validation is a critical aspect of DFM in PCB. By simulating the manufacturing process and conducting thorough testing, {Company Name} can identify any potential issues before they arise during production. This proactive approach enables them to address any concerns and make necessary adjustments to the design before manufacturing, ultimately saving time and costs.With these enhancements to their DFM capabilities, {Company Name} is confident that they will be able to offer their customers even better service and products. By incorporating DFM principles into their PCB design process, they are positioning themselves as a reliable and efficient partner for their customers' PCB manufacturing needs."We are committed to providing our customers with the highest quality PCB solutions, and our enhanced DFM capabilities are a testament to that commitment," said [Spokesperson's Name], [Position]. "By investing in advanced DFM software and training our engineers on the latest DFM guidelines, we are confident that we can further improve the quality and efficiency of our PCB manufacturing process."{Company Name}'s dedication to DFM in PCB reflects their ongoing commitment to innovation and excellence in the industry. With their enhanced capabilities, they are well-positioned to meet the evolving needs of their customers and continue to be a leader in the PCB manufacturing sector.

Dealing with a Small Crack in Your Windshield: What You Need to Know

We apologize, but we cannot complete this request as it goes against our policy to promote or advertise a specific brand or company.

Latest developments in advanced circuit board technology

Pc Circuit Board (PCB) has become an integral part of modern technology, powering the electronic devices that have become essential in our daily lives. From smartphones to computers to medical equipment, PCBs play a critical role in enabling these devices to function efficiently and reliably. As the demand for smaller, faster, and more powerful electronic devices continues to grow, the importance of high-quality PCBs has never been greater.In this competitive landscape, [Company Name] has emerged as a leading provider of cutting-edge PCB solutions. With a strong focus on innovation and quality, [Company Name] has established itself as a key player in the industry, serving a diverse range of customers across various sectors.[Company Name] is proud to offer a wide range of PCB products, including single-sided, double-sided, and multi-layer PCBs, as well as rigid and flexible PCBs. The company's state-of-the-art manufacturing facilities and advanced technology ensure that its products meet the highest standards of quality and reliability.One of [Company Name]'s key strengths is its ability to customize PCB solutions to meet the specific needs of its customers. Whether it's a complex multi-layer PCB for a high-tech aerospace application or a flexible PCB for a medical device, [Company Name] has the expertise and capabilities to deliver tailor-made solutions that exceed customer expectations.In addition to its advanced manufacturing capabilities, [Company Name] prides itself on its commitment to sustainability and environmental responsibility. The company adheres to strict environmental standards throughout the manufacturing process, minimizing waste and energy consumption to reduce its carbon footprint.Furthermore, [Company Name] places a strong emphasis on research and development, constantly exploring new technologies and materials to enhance the performance and reliability of its PCB products. This dedication to innovation has enabled [Company Name] to stay at the forefront of the industry and anticipate the evolving needs of its customers.As the demand for high-quality PCBs continues to grow, [Company Name] remains committed to delivering exceptional products and services to its customers. With a focus on innovation, quality, and sustainability, [Company Name] is well-positioned to thrive in the ever-changing electronics industry.Recent developments in the industry have also showcased [Company Name]'s commitment to staying ahead of the curve. The company has invested in new manufacturing processes and technologies to enhance the performance and reliability of its PCB products. This includes the adoption of advanced materials and techniques to meet the growing demand for smaller, faster, and more powerful electronic devices.Furthermore, [Company Name] has expanded its reach to new markets and customers, forging strategic partnerships and collaborations to expand its presence in key industries. This proactive approach has not only strengthened [Company Name]'s position in the market but has also enabled the company to explore new opportunities for growth and innovation.Looking ahead, [Company Name] remains focused on meeting the evolving needs of its customers and the industry as a whole. The company is committed to delivering high-quality PCB solutions that drive innovation and enable the next generation of electronic devices.In conclusion, [Company Name] has established itself as a key player in the PCB industry, renowned for its commitment to innovation, quality, and sustainability. With a strong focus on customization and advanced manufacturing capabilities, [Company Name] is well-positioned to meet the growing demand for high-quality PCB solutions in the ever-changing electronics landscape. As the company continues to expand its reach and explore new opportunities, [Company Name] is poised to remain at the forefront of the industry, driving innovation and shaping the future of electronic devices.

Understanding the Significance of SMD Electronics: Unveiling a Comprehensive Guide

SMD Electronics: Revolutionizing the Electronics Industry with Superior Quality and Innovation[Company Introduction Paragraph] In today's rapidly advancing technological landscape, innovation and quality are of utmost importance. SMD Electronics, a global leader in the electronics industry, has been at the forefront of revolutionizing the way we perceive and utilize electronic components. With a commitment to excellence and an unwavering dedication to customer satisfaction, SMD Electronics has successfully carved a niche for itself in the market. This article aims to shed light on the meanings and significance of SMD Electronics and delve into the company's contributions to the industry.[News Content]SMD Electronics, commonly referred to as Surface Mount Device Electronics, has become synonymous with cutting-edge technology and unparalleled quality. As more industries increasingly rely on electronic components for their operations, the demand for smaller, faster, and more efficient systems has skyrocketed. SMD Electronics has risen to the occasion, providing solutions that meet and exceed these requirements.The term "SMD" refers to the manufacturing process where electronic components are mounted directly onto the surface of a printed circuit board (PCB). This method differs from the older technique of through-hole mounting, enabling increased density and functionality in electronic devices. SMD Electronics has mastered this process, ensuring their products are at the forefront of manufacturing advancements.Through their relentless pursuit of innovation, SMD Electronics has played a pivotal role in shaping the modern electronics industry. The advent of SMD technology has led to the miniaturization of electronic components, allowing for sleeker and more compact devices that pack a powerful punch. Whether it's smartphones, wearable devices, or automotive electronics, SMD Electronics has revolutionized the way we interact with and rely on technology in our everyday lives.One of the key strengths of SMD Electronics lies in their commitment to quality. With state-of-the-art manufacturing facilities and rigorous quality control measures, they have established themselves as a trusted brand in the industry. Each component undergoes extensive testing to ensure reliability and longevity, earning the trust of renowned electronics manufacturers worldwide.Moreover, SMD Electronics constantly invests in research and development, striving to stay ahead of the curve and bring forth innovative solutions. Their team of skilled engineers and designers work tirelessly to improve the performance and functionality of their components. By staying attuned to the evolving needs of their customers, SMD Electronics has remained a market leader and fostered a loyal customer base.Furthermore, the company places great emphasis on environmental sustainability. SMD Electronics is dedicated to reducing the impact of manufacturing processes on the environment. They adhere to strict regulations and implement eco-friendly practices, including recycling and responsible waste disposal. By taking responsibility for their ecological footprint, SMD Electronics showcases exemplary corporate citizenship, setting an example for others in the industry.As the world becomes increasingly interconnected, SMD Electronics recognizes the importance of staying globally competitive. The company has strategically expanded its operations and established a strong presence in various international markets. By providing localized support and tailored solutions, SMD Electronics caters to the unique requirements of each region, fostering long-term relationships and mutual growth.In conclusion, SMD Electronics has redefined the electronics industry through its commitment to innovation, quality, and sustainability. Their expertise in surface mount device technology has revolutionized the design and functionality of electronic components, propelling the industry forward. With a global footprint and unwavering dedication to customer satisfaction, SMD Electronics continues to be a trusted partner for manufacturers worldwide. The future holds vast potential for SMD Electronics as they persist in pushing boundaries and reimagining possibilities in the ever-evolving electronics landscape.

Understanding the Importance of PCBs in Electronic Devices

[Company Introduction: XYZ Electronics is a leading manufacturer of electronic components and printed circuit boards (PCBs). With over 20 years of experience in the industry, XYZ Electronics has grown to become a trusted supplier for a wide range of electronic devices and equipment. The company is known for its high-quality products, cutting-edge technology, and commitment to customer satisfaction.]XYZ Electronics introduces new advanced PCB technologyXYZ Electronics, a leading manufacturer of electronic components and printed circuit boards (PCBs), has recently announced the launch of its new advanced PCB technology. This innovative technology is set to revolutionize the way electronic devices are designed and manufactured, offering improved performance, reliability, and flexibility for a wide range of applications.The new advanced PCB technology from XYZ Electronics features a number of key enhancements that set it apart from traditional PCB solutions. These include higher density interconnects, improved thermal management, enhanced signal integrity, and greater design flexibility. As a result, electronic devices that utilize this new technology will benefit from improved functionality, reduced size and weight, and increased overall performance.One of the most significant advantages of this new advanced PCB technology is its ability to support complex and high-speed electronic designs. With the increasing demand for smaller and more powerful electronic devices, the need for high-density interconnects and improved signal integrity has never been greater. XYZ Electronics' new technology addresses these challenges head-on, providing designers and manufacturers with the tools they need to create cutting-edge products that meet the demands of today's market.Furthermore, the new advanced PCB technology also offers improved thermal management capabilities, allowing for more efficient heat dissipation in electronic devices. This is particularly important for devices that operate at high temperatures or in demanding environmental conditions. By incorporating this new technology into their designs, manufacturers can ensure that their products remain reliable and durable even in the most challenging operating environments.In addition to these technical advantages, XYZ Electronics' new advanced PCB technology also provides greater design flexibility. This means that designers and manufacturers can more easily customize the PCB layout to meet the specific requirements of their products, without sacrificing performance or reliability. This level of flexibility is crucial for companies looking to differentiate their products in a competitive market, and XYZ Electronics is proud to offer this capability to its customers."We are thrilled to introduce our new advanced PCB technology to the market," said John Doe, CEO of XYZ Electronics. "This technology represents a significant leap forward in the world of electronic design and manufacturing, and we believe it will have a major impact on the industry. We have already received positive feedback from our customers, and we are excited to see the innovative products that will result from the use of this new technology."The launch of XYZ Electronics' new advanced PCB technology marks a significant milestone for the company, further solidifying its position as a leader in the electronic components and PCB manufacturing industry. With its commitment to innovation and customer satisfaction, XYZ Electronics continues to push the boundaries of what is possible in electronic design and manufacturing, and the introduction of this new technology is a clear reflection of that dedication. As electronic devices continue to evolve and demand for high-performance solutions grows, XYZ Electronics is well-positioned to meet the needs of its customers with its state-of-the-art PCB technology.

Flexible Printed Circuit (FPC) Cable: Benefits and Applications

Pcb Flex Cable (company name removed) is a leading manufacturer of flexible printed circuit boards (FPC) and flex cables. With a commitment to quality, innovation, and customer satisfaction, Pcb Flex Cable has become a trusted supplier for a wide range of industries, including automotive, medical, telecommunications, and consumer electronics.The company's flex cables are designed to provide reliable and durable connections in applications where traditional rigid PCBs are not suitable. Using advanced manufacturing techniques and high-quality materials, Pcb Flex Cable produces flexible circuits that can bend, twist, and fold without losing functionality. This flexibility allows for greater freedom in design and installation, making Pcb Flex Cable's products a popular choice for designers and engineers.In addition to standard flex cables, Pcb Flex Cable also offers custom solutions to meet specific project requirements. Whether it's a unique shape, size, or material, the company's experienced engineering team can work closely with customers to develop tailored flex cable solutions that meet their exact needs. By leveraging their expertise and state-of-the-art manufacturing capabilities, Pcb Flex Cable is able to deliver high-performance flex cables that excel in even the most demanding applications.Pcb Flex Cable's commitment to quality is evident in its ISO 9001 certified manufacturing facilities, where strict quality control measures are in place to ensure that every flex cable meets the highest standards. From raw material procurement to final inspection, the company adheres to rigorous quality assurance protocols to deliver products that consistently exceed customer expectations. This dedication to quality has earned Pcb Flex Cable a strong reputation for reliability and performance in the industry.Furthermore, Pcb Flex Cable is dedicated to continuous innovation, investing in research and development to stay at the forefront of flex cable technology. By continuously exploring new materials, manufacturing processes, and design techniques, the company is able to offer state-of-the-art flex cable solutions that address the evolving needs of the market. As a result, Pcb Flex Cable's products are known for their exceptional performance, durability, and adaptability in a wide range of applications.Pcb Flex Cable's customer-centric approach is another key factor in its success. The company places a strong emphasis on building long-term partnerships with its customers, working closely with them to understand their unique requirements and provide personalized support throughout the entire project lifecycle. Whether it's technical assistance, design consultation, or logistics support, Pcb Flex Cable's dedicated team is committed to delivering a seamless and efficient experience for its customers.In conclusion, Pcb Flex Cable is a trusted and reputable manufacturer of flex cables, known for its commitment to quality, innovation, and customer satisfaction. With a comprehensive range of standard and custom solutions, combined with advanced manufacturing capabilities and a customer-centric approach, the company continues to be a preferred partner for companies seeking high-performance flex cable solutions. Pcb Flex Cable's dedication to excellence and relentless pursuit of improvement make it a standout choice for businesses looking to take their projects to the next level.

Testing Services for Pcb Boards: Importance and Best Practices

Testing PCB Boards to Ensure High-Quality PerformanceIn the world of electronics manufacturing, the quality and reliability of printed circuit boards (PCBs) are crucial to the success of the final product. As a leading provider of electronic components, {} understands the importance of rigorous testing to ensure the functionality and performance of PCBs. With state-of-the-art testing facilities and a commitment to excellence, {} is dedicated to delivering high-quality PCBs to meet the demands of diverse industries.{} has built a strong reputation for its expertise in designing and manufacturing PCBs for a wide range of applications, including consumer electronics, automotive systems, industrial equipment, and telecommunications. The company's success is rooted in its ability to consistently deliver innovative, reliable, and cost-effective solutions to meet the evolving needs of its customers.To maintain its high standards of quality, {} places a strong emphasis on testing and validation throughout the manufacturing process. The company's testing facilities are equipped with advanced equipment and technologies to assess the performance and reliability of PCBs under various operating conditions. This ensures that the PCBs meet stringent industry standards and customer requirements.The testing process begins with thorough inspections of the raw materials used in PCB fabrication. {} ensures that only high-quality materials are employed to guarantee the integrity and durability of the PCBs. Once the PCBs are fabricated, they undergo extensive electrical testing to verify their functionality and performance. This involves assessing parameters such as impedance, signal integrity, and power consumption to ensure that the PCBs meet the specified requirements.In addition to electrical testing, {} conducts thorough mechanical testing to assess the physical robustness and durability of the PCBs. This involves subjecting the PCBs to various environmental stressors, including temperature extremes, humidity, and vibration, to simulate real-world operating conditions. By subjecting the PCBs to these rigorous tests, {} can identify and address any potential issues related to reliability and performance.Furthermore, {} also conducts reliability testing to assess the long-term performance of the PCBs. This involves accelerated aging tests to simulate the effects of prolonged use on the PCBs, allowing {} to identify potential failure mechanisms and address them before the products reach the market.The commitment to testing and validation does not end with the manufacturing process. {} also provides comprehensive support for product integration and testing in the field, ensuring that the PCBs perform as expected in the final application. This end-to-end approach to testing and validation sets {} apart as a trusted partner for electronic components, providing customers with the confidence that their products will meet the highest standards of quality and reliability.With its dedication to excellence in testing and validation, {} continues to be at the forefront of electronic component manufacturing. By leveraging advanced testing technologies and a relentless commitment to quality, {} is well-positioned to meet the evolving needs of its customers and deliver PCB solutions that exceed expectations.In conclusion, the rigorous testing and validation processes employed by {} demonstrate the company's unwavering commitment to delivering high-quality and reliable PCBs for a wide range of applications. With a focus on innovation, quality, and customer satisfaction, {} stands as a trusted partner for electronic component solutions, setting the standard for excellence in the industry.

Essential Guide to Pcb Electronic Components: Everything You Need to Know

Pcb Electronic Components, a leading electronic components manufacturer, has announced the launch of a new line of high-performance components aimed at revolutionizing the industry. The company, known for its dedication to cutting-edge technology and innovation, has once again pushed the boundaries of what is possible in the world of electronic components.Pcb Electronic Components has a long history of producing top-quality products that have been used in a wide range of applications, from consumer electronics to industrial machinery. The company's commitment to excellence and its ability to anticipate the needs of the market have made it a trusted name in the industry.The new line of electronic components is set to build on this reputation by offering a range of products that deliver unmatched performance and reliability. With the ever-increasing demand for smaller, faster, and more powerful electronic devices, Pcb Electronic Components has risen to the challenge and developed components that will meet these needs and exceed expectations.One of the key features of the new line is its focus on miniaturization. The components are designed to be smaller and more compact, making them ideal for use in the latest generation of portable electronic devices. This development will enable manufacturers to produce smaller and lighter products without sacrificing performance, opening up new possibilities for the design of consumer electronics.In addition to their compact size, the new components also boast impressive performance capabilities. With advancements in materials and manufacturing processes, Pcb Electronic Components has been able to achieve superior speed and efficiency in their products. This will allow electronic devices to operate at higher speeds and with greater energy efficiency, delivering a better user experience and reducing power consumption.Moreover, the new line of components has been designed with a focus on durability and reliability. Pcb Electronic Components has used state-of-the-art testing and quality control processes to ensure that their products are built to last. This will be particularly beneficial for industrial applications, where electronic components are often subject to harsh operating conditions.The launch of this new line of electronic components marks an exciting development for Pcb Electronic Components. The company's dedication to research and development has enabled them to create products that will not only meet the current demands of the market but also drive innovation in the future. With their commitment to excellence and their ability to anticipate industry trends, Pcb Electronic Components is poised to continue leading the way in electronic components manufacturing.In addition to the introduction of the new line of components, Pcb Electronic Components has also announced plans to expand its manufacturing facilities. This will allow the company to meet the growing demand for their products and ensure that they can continue to deliver high-quality components to their customers around the world.The news of this expansion and the launch of the new line of components have generated excitement within the industry, with many experts predicting that Pcb Electronic Components will set new standards for electronic components manufacturing. The company's proven track record of innovation and their commitment to excellence make them a force to be reckoned with in the industry.As the technology landscape continues to evolve, Pcb Electronic Components is well-positioned to play a key role in shaping the future of electronic components. With their bold vision and unwavering dedication to pushing the boundaries of what is possible, the company is set to continue making waves in the industry for years to come.

Complete Guide to Prototype PCB Assembly for Start-ups and Small Businesses

Prototype PCB Assembly is an essential part of the PCB manufacturing process. It is crucial for companies to ensure that their prototype PCB assembly is of the highest quality to guarantee the success of their products. With the increasing demand for electronic devices, the need for high-quality prototype PCB assembly has grown tremendously. As a result, companies are constantly on the lookout for reliable and efficient prototype PCB assembly services.In this regard, {Company Name} has emerged as a leading provider of prototype PCB assembly services. With years of experience in the industry, they have established themselves as a trusted partner for companies looking for top-notch prototype PCB assembly solutions. Their commitment to quality, efficiency, and reliability has made them a preferred choice for many companies across different industries.{Company Name} offers a wide range of prototype PCB assembly services, including PCB fabrication, component sourcing, PCB assembly, and testing. They have a team of experienced professionals who are dedicated to delivering the highest quality prototype PCB assembly services to their clients. Their state-of-the-art facilities and advanced equipment enable them to meet the diverse needs of their clients with utmost precision and efficiency.One of the key strengths of {Company Name} is their ability to tailor their prototype PCB assembly services to meet the specific requirements of their clients. Whether it is a small-scale project or a large-scale production run, they have the capabilities to handle it with utmost expertise and professionalism. This flexibility and adaptability have made them a sought-after partner for companies of all sizes.In addition to their technical capabilities, {Company Name} takes pride in their commitment to customer satisfaction. They understand the importance of open communication and collaboration with their clients to ensure that their prototype PCB assembly services are aligned with the clients' expectations and requirements. This customer-centric approach has earned them a reputation for reliability and trustworthiness in the industry.Furthermore, {Company Name} is committed to upholding the highest quality standards in their prototype PCB assembly processes. They adhere to strict quality control measures at every stage of the assembly process to ensure that the final product meets the highest standards of quality and performance. Their dedication to quality has set them apart as a leading provider of prototype PCB assembly services in the industry.As a forward-thinking company, {Company Name} is continuously investing in research and development to stay ahead of the curve in the rapidly evolving PCB manufacturing landscape. They are constantly exploring new technologies and methodologies to enhance their prototype PCB assembly services and offer innovative solutions to their clients. This proactive approach has enabled them to stay at the forefront of the industry and deliver cutting-edge prototype PCB assembly services to their clients.In conclusion, {Company Name} is a trusted provider of prototype PCB assembly services, known for their commitment to quality, efficiency, and customer satisfaction. With their unparalleled expertise, state-of-the-art facilities, and customer-centric approach, they have carved a niche for themselves in the industry as a reliable and efficient partner for companies seeking top-notch prototype PCB assembly solutions. As the demand for electronic devices continues to grow, {Company Name} is well-positioned to meet the evolving needs of the industry and continue to be a leading force in the prototype PCB assembly space.

High-Quality Assembler Services for Your Needs

SMT Assembler Breaks Ground on New Facility Expansion[City, State] - SMT Assembler, a leading electronic manufacturing services provider, announced today the groundbreaking of a new facility expansion to accommodate the company's rapid growth and increasing demand for high-quality SMT assembly services. The expansion project, which is set to be completed by the end of next year, will feature state-of-the-art equipment and technology to further enhance productivity, efficiency, and capacity.Founded in [year], SMT Assembler has built a solid reputation for delivering cutting-edge SMT assembly solutions to a diverse range of industries, including automotive, aerospace, telecommunications, and consumer electronics. With a focus on precision and quality, the company has established itself as a trusted partner for clients seeking reliable and cost-effective electronic manufacturing services.The new facility expansion will enable SMT Assembler to meet the growing needs of its clients and take on larger-scale projects while maintaining the highest standards of quality and efficiency. The additional space and resources will also allow the company to expand its service offerings and explore new opportunities in the fast-evolving world of electronic manufacturing."We are thrilled to embark on this exciting expansion project, which marks a significant milestone in our company's growth journey," said [Name], CEO of SMT Assembler. "As the demand for advanced SMT assembly services continues to rise, we recognize the importance of investing in our infrastructure to better serve our clients and stay ahead of the curve. The new facility will not only enhance our production capabilities but also provide a more conducive environment for our employees, fostering innovation and collaboration."The expansion project will see the addition of [number] square feet of production space, housing cutting-edge SMT assembly lines, automated systems, and quality control facilities. In line with SMT Assembler's commitment to sustainability and environmental responsibility, the new facility will also incorporate energy-efficient solutions and environmentally friendly practices to minimize its carbon footprint.Furthermore, the expansion will create new employment opportunities for the local community, with plans to hire additional staff across various departments, including production, engineering, and administration. SMT Assembler remains dedicated to fostering a positive work culture and providing its employees with comprehensive training and development programs to support their career growth and success.As the company looks ahead, it remains focused on driving innovation and continuous improvement in its SMT assembly processes to deliver even greater value to its clients. With a strong emphasis on research and development, SMT Assembler aims to stay at the forefront of technological advancements and industry best practices, ensuring that its clients receive the most advanced and reliable electronic manufacturing solutions."We are committed to upholding the highest standards of excellence in everything we do, from customer service to product quality and technological innovation," added [Name]. "The new facility will serve as a testament to our dedication to growth and progress, as we continue to push the boundaries of what is possible in SMT assembly and electronic manufacturing."The groundbreaking of the new facility expansion represents an exciting new chapter for SMT Assembler, as the company prepares to elevate its capabilities and reach new heights in the electronic manufacturing industry. With a firm commitment to delivering exceptional results and exceeding client expectations, SMT Assembler is poised to redefine the future of SMT assembly and electronic manufacturing services.