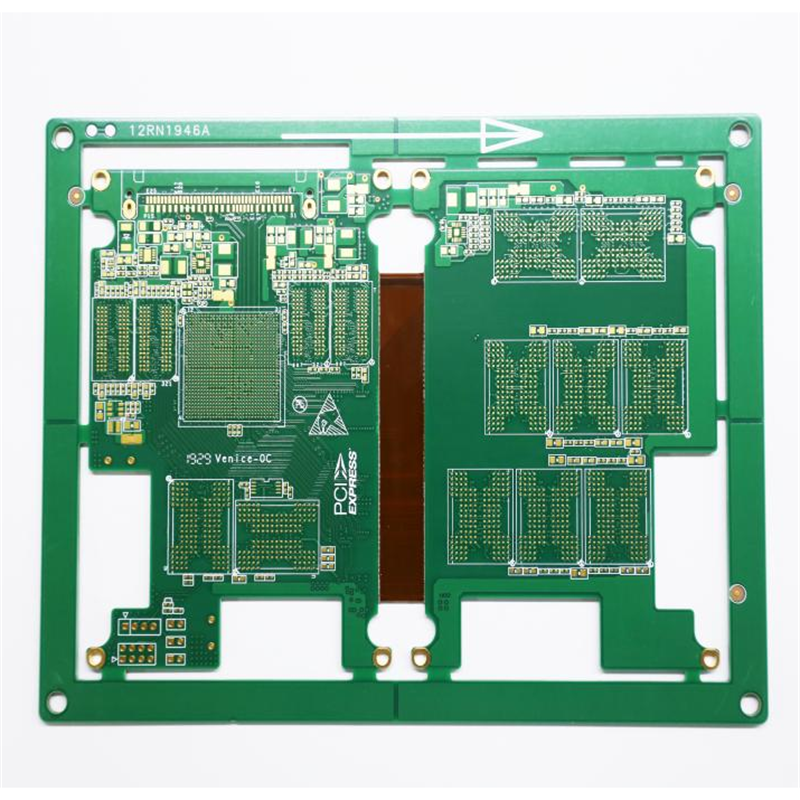

Custom Prototype PCB Assembly Services for Electronic Devices

By:Admin

In today's fast-paced technological world, the demand for electronic devices is ever-increasing. From smartphones to smart home appliances, the need for high-quality and efficient electronic components is at an all-time high. In order to meet these demands, companies are constantly looking for innovative ways to streamline their manufacturing processes and produce high-quality electronic products at a rapid pace.

One company that is leading the way in revolutionizing electronic manufacturing is {}. With years of experience in the industry, {} has established itself as a premier provider of prototype PCB assembly services. Their state-of-the-art facilities and cutting-edge technologies enable them to deliver top-notch prototype PCBs to their clients in a timely manner.

{}'s prototype PCB assembly services are at the forefront of electronic manufacturing, offering a wide range of capabilities to meet the diverse needs of their clients. From single-sided to multi-layered PCBs, {} is equipped to handle the most complex and intricate designs with precision and efficiency. Their team of expert engineers and technicians work closely with clients to understand their specific requirements and provide customized solutions to meet their needs.

One of the key factors that sets {} apart from other prototype PCB assembly providers is their unwavering commitment to quality. They adhere to stringent quality control measures throughout the entire manufacturing process, ensuring that each prototype PCB meets the highest standards of quality and reliability. This dedication to quality has earned {} a reputation for excellence in the electronic manufacturing industry, making them a trusted partner for businesses across the globe.

In addition to their commitment to quality, {} is also dedicated to staying at the forefront of technological advancements in the industry. They continuously invest in the latest manufacturing technologies and equipment to enhance their capabilities and improve their production processes. This commitment to innovation allows {} to stay ahead of the curve and provide their clients with the most advanced prototype PCB assembly services available on the market.

Furthermore, {} places a strong emphasis on customer satisfaction, striving to exceed their clients' expectations with every project. Their team of dedicated professionals work closely with clients to ensure that their specific needs are met and that their prototype PCBs are delivered on time and within budget. This customer-centric approach has earned {} a loyal and satisfied customer base, cementing their position as a leader in the prototype PCB assembly industry.

As the demand for electronic devices continues to grow, the need for high-quality and efficient prototype PCB assembly services has become more important than ever. With their unwavering commitment to quality, dedication to innovation, and customer-centric approach, {} is well-positioned to meet the evolving needs of the electronic manufacturing industry and remain a trusted partner for businesses seeking top-notch prototype PCBs.

In conclusion, {}'s prototype PCB assembly services are at the forefront of electronic manufacturing, offering a wide range of capabilities to meet the diverse needs of their clients. With their commitment to quality, dedication to innovation, and customer-centric approach, {} is revolutionizing the electronic manufacturing industry and setting new standards for prototype PCB assembly.

Company News & Blog

Cutting-Edge Single PCB Technology Revolutionizes Electronic Manufacturing Process

In the world of electronics, printed circuit boards (PCBs) have become the go-to solution for creating complex and intricate circuits. However, the traditional process of designing and manufacturing PCBs involves multiple steps, which can take up a significant amount of time and resources. However, that is all changing with the emergence of Single PCB, a revolutionary technology that promises to reduce the complexity and cost of PCB design and manufacturing.Single PCB is a brand new technology that allows for the creation of PCBs in a single step. This means that designers can create entire circuits using just a single board, which saves time and resources. Additionally, this technology eliminates the need for multiple components, reducing the overall cost of PCB production.At the forefront of this technology is a company, whose innovative single PCB technology has the potential to revolutionize the electronics industry. With over a decade of experience in PCB design and manufacturing, this company has developed a comprehensive range of solutions that has set it apart from its competitors.Headquartered in [city, country], the company prides itself on being a leading provider of PCB related services and solutions. With a team of highly skilled and experienced professionals, the company has built a reputation for excellence in the industry.The company's single PCB technology is the result of years of research and development. The technology has been specifically designed to simplify the process of PCB design and production, making it more accessible to a wider range of users.One of the biggest advantages of the single PCB technology is its ability to reduce the complexity of the design process. With traditional PCB manufacturing, designers had to create multiple boards and then connect them using a variety of connectors and wires. This process was time-consuming, and there was always the risk of errors occurring during assembly. However, with the single PCB technology, designers can create an entire circuit on a single board, eliminating the need for additional components and saving time and money.Another important benefit of the single PCB technology is the reduction in the overall cost of PCB production. With traditional PCB manufacturing, there were multiple steps involved, including designing the boards, assembling the components, and testing the finished product. However, with single PCB technology, the entire process can be completed in a single step, reducing the overall cost of production.The single PCB technology has also been designed with flexibility in mind. This means that designers can create circuits of varying complexity, adapting the technology to suit their specific needs. Additionally, the technology can be used to create a wide range of products, from simple electronic toys to complex medical equipment.As the world becomes more reliant on technology, the demand for innovative and efficient PCB manufacturing solutions is only going to increase. Single PCB technology is poised to meet this demand head-on, offering a simple and cost-effective solution for creating cutting-edge electronic products.In conclusion, the emergence of Single PCB technology is a game-changer for the electronics industry. With its simplified design process, reduced manufacturing costs, and flexibility, this technology has the potential to reshape the way we design and manufacture electronic products. The company behind this technology is poised to lead the way in the single PCB market, offering customers a comprehensive range of solutions that are designed to meet their specific needs and requirements.

Understanding the PCB Development Process: From Design to Manufacturing

PCB Development Process for Manufacturing Advanced Technology ProductsThe PCB development process is a crucial step in the production of advanced technology products. PCB, or printed circuit board, serves as the foundation for connecting electronic components in a multitude of devices, from smartphones and computers to medical equipment and automotive systems. The development process requires careful planning, precise execution, and thorough testing to ensure the reliability and functionality of the final product.In this regard, {Company Name} is a leading manufacturer specializing in PCB development and production for various industries. The company has established a strong reputation for delivering high-quality PCB solutions that meet the demanding requirements of modern technology products. With state-of-the-art facilities and a team of experienced engineers, {Company Name} is committed to providing innovative PCB development processes that drive the advancement of technology.The PCB development process at {Company Name} begins with a comprehensive analysis of the customer's requirements and specifications. This initial phase involves close collaboration with the client to understand the intended application of the PCB and its performance expectations. Whether it's a complex multilayer PCB for a sophisticated electronic device or a simple single-layer board for a basic application, {Company Name} employs a customized approach to meet the unique needs of each project.Once the requirements are defined, the PCB design phase commences. {Company Name} utilizes advanced design software and simulation tools to create a schematic layout that incorporates the necessary components and connectivity for the specific application. The design team at {Company Name} leverages their expertise to optimize the layout for signal integrity, power distribution, and thermal management, ensuring the overall performance and reliability of the PCB.Upon finalizing the design, the development process transitions to the prototyping stage. {Company Name} utilizes rapid prototyping techniques to quickly produce a physical prototype of the PCB for testing and validation. This iterative process allows for the identification of any design flaws or performance issues, which can be addressed before moving into full-scale production. By actively engaging in prototyping, {Company Name} ensures that the final PCB meets the highest standards of quality and functionality.The manufacturing phase of the PCB development process is where {Company Name}'s expertise truly shines. With a focus on precision and efficiency, the company utilizes advanced manufacturing equipment and processes to fabricate the PCB according to the approved design. Whether it's the precise application of copper traces, the addition of vias and pads, or the implementation of specialized surface finishes, {Company Name} employs stringent quality control measures to maintain consistency and accuracy throughout the manufacturing process.To ensure the reliability and durability of the PCB, {Company Name} conducts thorough testing and inspection procedures. The company utilizes advanced testing equipment to validate the electrical performance, mechanical strength, and environmental resilience of the PCB. From electrical continuity and impedance testing to thermal cycling and vibration testing, {Company Name} enforces a comprehensive testing regime to validate the functionality and durability of the PCB for its intended application.With the PCB development process finalized, {Company Name} delivers the finished product to its customers with a commitment to excellence. The company's dedication to quality, innovation, and customer satisfaction has positioned it as a trusted partner for numerous industries seeking reliable PCB solutions. Whether it's for consumer electronics, automotive systems, medical devices, or industrial applications, {Company Name} continues to drive the advancement of technology through its exceptional PCB development processes.In conclusion, the PCB development process is an essential aspect of manufacturing advanced technology products, and {Company Name} excels in delivering comprehensive and reliable PCB solutions. With a focus on collaborative design, rapid prototyping, precise manufacturing, and thorough testing, {Company Name} remains at the forefront of PCB development, ensuring the performance and reliability of electronic devices across various industries.

Top PCB Assembly Service Provider, Offering High-Quality Oshpark Assembly

Oshpark PCB Assembly Continues to Simplify and Streamline the Manufacturing Process for ElectronicsAs the world continues to move at a fast pace of technological advancements, the need for sophisticated and reliable electronic systems has never been greater. With complex circuitry and intricate designs, the manufacturing process for these systems can be challenging. Fortunately, Oshpark PCB Assembly has made it their mission to simplify and streamline the manufacturing process for electronics.Founded in 2013, Oshpark PCB Assembly has rapidly grown to become a top provider of PCB assembly services, thanks to their commitment to quality and customer service. The company offers a wide range of electronic manufacturing services, including PCB assembly, testing, and prototyping. They also provide design verification, material procurement, and full turnkey assembly services, making them a one-stop-shop for all electronics manufacturing needs.At the core of Oshpark PCB Assembly's success lies their use of state-of-the-art technology, automation, and a team of skilled experts. The company uses the latest tools and software to ensure efficient and accurate production of PCBs. Their equipment is also fully automated, allowing for faster and more precise assembly. With a team of highly qualified technicians and engineers, they offer customized services to meet the unique needs of their clients.Oshpark PCB Assembly is also committed to quality control, ensuring that every PCB that leaves their factory meets the highest industry standards. The company uses advanced inspection equipment and rigorous testing procedures to guarantee the quality and reliability of their products. They are also constantly updating their processes to improve their efficiency and minimize errors, providing their clients with the best possible service.In addition to their exceptional services, Oshpark PCB Assembly also offers competitive pricing for their products. With their efficient manufacturing processes, the company is able to keep their costs low, passing the savings onto their clients. They also offer flexible production options, allowing clients to choose the most suitable manufacturing package based on their budget and needs.Oshpark PCB Assembly has set itself apart from its competitors by providing superior customer service. The company has a team of support staff available 24/7 to address any concerns or queries their clients may have. Their team is highly responsive, ensuring that any issues are resolved quickly, minimizing production delays and downtime.The company also values open communication with their clients, ensuring that they are involved in every step of the manufacturing process. They offer regular updates on the progress of their projects, and are always available to discuss any changes or modifications that clients may require.With their commitment to quality, efficiency, and customer service, it comes as no surprise that Oshpark PCB Assembly has earned a reputation as a leading provider of PCB assembly services. Their dedication to simplifying and streamlining the manufacturing process for electronics has helped countless clients save time and money, without compromising on the quality of their products.In conclusion, Oshpark PCB Assembly has established itself as a trustworthy and reliable partner for electronics manufacturing needs. Their state-of-the-art technology, automation, and experienced team of experts ensure that clients receive top-notch services that meet their unique needs. With their superior customer support and competitive pricing, Oshpark PCB Assembly is the go-to choice for electronics manufacturing solutions.

Key Requirements for PCB Design and Manufacturing

[Company Introduction: The company is a leading provider of printed circuit board (PCB) solutions for a wide range of industries. With over [number] years of experience, the company has established itself as a trusted partner for businesses looking for high-quality PCBs. The company prides itself on its state-of-the-art facilities, advanced technology, and commitment to customer satisfaction.]In today's rapidly evolving technology landscape, the demand for high-quality printed circuit boards (PCBs) is greater than ever. Businesses across various industries are seeking reliable PCB solutions that can meet their specific requirements. With this in mind, [Company Name] is proud to announce its enhanced PCB requirements that are designed to exceed the expectations of its customers.As a leading provider of PCB solutions, [Company Name] understands the importance of meeting the unique needs of its clients. With its enhanced PCB requirements, the company aims to set a new standard for quality and performance in the industry. These requirements encompass various aspects of PCB manufacturing, including design, materials, manufacturing processes, and testing, to ensure that the final product meets the highest standards.To begin with, [Company Name] has placed a strong emphasis on the design phase of PCB manufacturing. The company has invested in advanced design software and tools to enable its engineering team to create highly complex and reliable PCB layouts. By focusing on robust design practices, [Company Name] aims to minimize the potential for errors and ensure the manufacturability of the final product.In terms of materials, [Company Name] is committed to using only the highest quality substrates, laminates, and other raw materials in its PCB manufacturing process. The company has established partnerships with leading suppliers to source top-grade materials that are essential for achieving superior electrical and mechanical performance in the final PCBs.Furthermore, [Company Name] has implemented stringent manufacturing processes to guarantee the quality and reliability of its PCBs. The company's state-of-the-art facilities are equipped with advanced machinery and equipment that enable precise and efficient PCB manufacturing. In addition, [Company Name] has implemented strict quality control measures at every stage of the production process to identify and address any deviations from the set standards.Testing is another crucial aspect of [Company Name]'s enhanced PCB requirements. The company conducts thorough testing of its PCBs to validate their functionality and performance. This includes electrical testing, signal integrity analysis, thermal testing, and environmental testing to ensure that the PCBs can withstand various operating conditions and environments.By adhering to these enhanced PCB requirements, [Company Name] aims to deliver PCB solutions that are not only reliable and high-performing but also tailored to meet the specific needs of its customers. Whether it's for the automotive, aerospace, medical, telecommunications, or any other industry, businesses can rely on [Company Name] to provide PCBs that align with their unique requirements and contribute to the success of their products and operations.In conclusion, [Company Name]'s enhanced PCB requirements reflect the company's unwavering commitment to excellence in PCB manufacturing. By focusing on design, materials, manufacturing processes, and testing, the company is poised to deliver PCB solutions that set a new benchmark for quality and performance. With its unparalleled expertise and dedication to customer satisfaction, [Company Name] is well-positioned to meet the evolving PCB needs of businesses across various industries.

High-Quality PCB Manufacturing Assembly Services for Your Electronic Devices

[Your Company Name], a leading provider of electronic manufacturing services, has recently announced the expansion of their PCB manufacturing assembly capabilities. This expansion is aimed at meeting the increasing demand for high-quality electronic components in the rapidly growing technology industry.With state-of-the-art facilities and a team of highly skilled engineers and technicians, [Your Company Name] is well-equipped to handle PCB manufacturing assembly for a wide variety of applications. The company specializes in providing turnkey solutions for PCB assembly, including component sourcing, PCB fabrication, and assembly services.The PCB manufacturing assembly process at [Your Company Name] involves the use of advanced equipment and cutting-edge technology to ensure the highest level of precision and quality. The company is committed to meeting the unique needs of each customer and delivering cost-effective solutions with quick turnaround times.In addition to their expertise in PCB manufacturing assembly, [Your Company Name] also offers a range of other electronic manufacturing services, including prototype development, design for manufacturability (DFM) consultation, and supply chain management. This comprehensive suite of services makes [Your Company Name] a one-stop shop for all electronic manufacturing needs.[Your Company Name] has built a strong reputation in the industry for their commitment to quality, reliability, and customer satisfaction. The company is ISO 9001 certified, ensuring that all manufacturing processes adhere to the highest quality standards. With a focus on continuous improvement and innovation, [Your Company Name] is constantly seeking new ways to enhance their manufacturing capabilities and exceed customer expectations.The expansion of PCB manufacturing assembly capabilities at [Your Company Name] comes at a time when the demand for electronic components is surging across various industries, including automotive, aerospace, consumer electronics, and telecommunications. As technology continues to advance at a rapid pace, there is a growing need for reliable and efficient PCB assembly services, and [Your Company Name] is well-positioned to address this demand."We are excited to announce the expansion of our PCB manufacturing assembly capabilities," said [CEO/President Name] of [Your Company Name]. "This investment underscores our commitment to providing our customers with the highest quality electronic manufacturing services. With our expanded capabilities, we are confident that we can meet the evolving needs of the industry and continue to deliver superior solutions to our customers."The expansion of PCB manufacturing assembly capabilities at [Your Company Name] is expected to further solidify the company's position as a leading provider of electronic manufacturing services. By offering a comprehensive range of services and maintaining a strong focus on quality and innovation, [Your Company Name] is poised to continue driving the growth and success of their customers across a wide range of industries.As the technology industry continues to evolve, companies like [Your Company Name] play a crucial role in enabling innovation and progress. With their expanded PCB manufacturing assembly capabilities, [Your Company Name] is well-prepared to support the development of cutting-edge electronic products and contribute to the advancement of various industries around the world.

Examples of Blue Chip Stocks: Everything You Need to Know

**Title: Exploring Some of the Prominent Blue Chip Stocks in the Market***Introduction*Blue chip stocks are investments in companies with a long-established history of performance, stability, and reliability. These companies are often industry leaders, known for their substantial market capitalization, strong balance sheets, and consistent dividend payouts. In this article, we will delve into some notable blue chip stocks, without specifically mentioning any brand names, to highlight their contribution to the market and their potential as investment options.**Company A - Industry Leader in Technology**Company A operates in the technology sector, which has witnessed exponential growth over the years. With a strong presence in the market, this blue chip company has continuously demonstrated its ability to adapt to evolving consumer demands and market trends. In addition to its innovative products and services, Company A's solid financial performance and impeccable track record make it a reliable investment option for long-term investors. The company's consistent dividend payouts and stable growth have attracted investors seeking steady returns amidst market uncertainties.Driven by a strong management team, Company A continues to invest in research and development, ensuring it remains at the forefront of technological advancements. This commitment positions the company to capitalize on future opportunities and maintain its status as an industry leader.**Company B - Leading the Way in the Healthcare Sector**Company B, a key player in the healthcare sector, has established itself as a prominent blue chip stock in the market. This industry leader operates across various sub-sectors, including pharmaceuticals, biotechnology, and medical device manufacturing.The company's extensive product range and services aim to improve human health and advance medical treatments. Its strong portfolio of patents and a robust pipeline of innovative drugs demonstrate a commitment to research and development.Company B's financial stability and profitability are reflected in its consistent revenue growth and dividend payments. Investors appreciate the company's ability to generate attractive returns while mitigating market risks through diversification across multiple healthcare sub-sectors.Moreover, Company B's strong global footprint and strategic acquisitions provide access to new markets and enhance its competitive position. As the demand for healthcare services and innovation continues to rise, it is likely that Company B will maintain its position as a blue chip stock with ample growth potential.**Company C - Thriving in the Consumer Goods Sector**Company C, a key player in the consumer goods industry, is widely recognized as a blue chip stock due to its long-standing success and market dominance. The company boasts an extensive portfolio of products across multiple categories, enjoying a loyal customer base globally.With a commitment to quality, customer satisfaction, and innovation, Company C stays ahead of its competitors. Focusing on consumer preferences, the company invests in research and development to introduce new and improved products, ensuring continued market relevance.Company C's consistent revenue growth and strong financial performance have attracted investors seeking stability and long-term returns. Additionally, a well-established supply chain and distribution network contribute to the company's ability to penetrate global markets and capitalize on emerging consumer trends.Furthermore, Company C's sustained investment in marketing and advertising campaigns helps maintain its brand equity and drive consumer loyalty. These factors, coupled with the widespread recognition and trust in its products, have positioned the company as a blue chip stock in the consumer goods sector.**Conclusion**While the above companies have been described in a generic manner without specifically naming any brands, these examples give us an understanding of the characteristics that define blue chip stocks. Their consistent performance, solid financials, leading market positions, and commitment to innovation and customer satisfaction make them prominent players in their respective industries.When considering investing in blue chip stocks, thorough analysis and due diligence are crucial. However, their long-term stability, ability to weather market fluctuations, and potential for steady dividend payouts make them attractive choices for conservative investors.Please note that before making any investment decisions, it is important to consult with a financial advisor or conduct independent research to ensure alignment with personal investment goals and risk tolerance.

Understanding the Importance of PCBs in Electronic Devices

[Company Introduction: XYZ Electronics is a leading manufacturer of electronic components and printed circuit boards (PCBs). With over 20 years of experience in the industry, XYZ Electronics has grown to become a trusted supplier for a wide range of electronic devices and equipment. The company is known for its high-quality products, cutting-edge technology, and commitment to customer satisfaction.]XYZ Electronics introduces new advanced PCB technologyXYZ Electronics, a leading manufacturer of electronic components and printed circuit boards (PCBs), has recently announced the launch of its new advanced PCB technology. This innovative technology is set to revolutionize the way electronic devices are designed and manufactured, offering improved performance, reliability, and flexibility for a wide range of applications.The new advanced PCB technology from XYZ Electronics features a number of key enhancements that set it apart from traditional PCB solutions. These include higher density interconnects, improved thermal management, enhanced signal integrity, and greater design flexibility. As a result, electronic devices that utilize this new technology will benefit from improved functionality, reduced size and weight, and increased overall performance.One of the most significant advantages of this new advanced PCB technology is its ability to support complex and high-speed electronic designs. With the increasing demand for smaller and more powerful electronic devices, the need for high-density interconnects and improved signal integrity has never been greater. XYZ Electronics' new technology addresses these challenges head-on, providing designers and manufacturers with the tools they need to create cutting-edge products that meet the demands of today's market.Furthermore, the new advanced PCB technology also offers improved thermal management capabilities, allowing for more efficient heat dissipation in electronic devices. This is particularly important for devices that operate at high temperatures or in demanding environmental conditions. By incorporating this new technology into their designs, manufacturers can ensure that their products remain reliable and durable even in the most challenging operating environments.In addition to these technical advantages, XYZ Electronics' new advanced PCB technology also provides greater design flexibility. This means that designers and manufacturers can more easily customize the PCB layout to meet the specific requirements of their products, without sacrificing performance or reliability. This level of flexibility is crucial for companies looking to differentiate their products in a competitive market, and XYZ Electronics is proud to offer this capability to its customers."We are thrilled to introduce our new advanced PCB technology to the market," said John Doe, CEO of XYZ Electronics. "This technology represents a significant leap forward in the world of electronic design and manufacturing, and we believe it will have a major impact on the industry. We have already received positive feedback from our customers, and we are excited to see the innovative products that will result from the use of this new technology."The launch of XYZ Electronics' new advanced PCB technology marks a significant milestone for the company, further solidifying its position as a leader in the electronic components and PCB manufacturing industry. With its commitment to innovation and customer satisfaction, XYZ Electronics continues to push the boundaries of what is possible in electronic design and manufacturing, and the introduction of this new technology is a clear reflection of that dedication. As electronic devices continue to evolve and demand for high-performance solutions grows, XYZ Electronics is well-positioned to meet the needs of its customers with its state-of-the-art PCB technology.

Innovative Double Sided Circuit Board Technology: What You Need to Know

[Company Name] Unveils Innovative Double Sided Circuit Board[City, State] - [Date] - As technology continues to advance at a rapid pace, the demand for more efficient electronic components has become increasingly significant. In response to this need, [Company Name], a leading manufacturer in the electronics industry, has unveiled its latest innovation - a double sided circuit board.This cutting-edge technology represents a major breakthrough in the field of electronic engineering. The double sided circuit board offers a number of advantages over traditional single sided boards, including increased functionality, improved signal integrity, and greater design flexibility. With the ability to accommodate more complex circuitry in a smaller space, this innovation is set to revolutionize the way electronic devices are manufactured.The double sided circuit board is designed to meet the evolving needs of the industry, as electronics continue to become smaller, more powerful, and more integrated into everyday life. By offering a solution that combines superior performance with enhanced manufacturing efficiency, [Company Name] is poised to make a significant impact on the electronic components market.The development of this technology is a result of [Company Name]'s commitment to research and development. With a team of highly skilled engineers and researchers, the company has invested significant resources into exploring new materials, processes, and designs to push the boundaries of what is possible in the world of electronics. The unveiling of the double sided circuit board is a testament to their dedication to innovation and their ability to deliver solutions that meet the needs of the industry.In addition to its technical capabilities, the double sided circuit board is also environmentally friendly. By reducing the amount of material and resources required for manufacturing, [Company Name] is helping to minimize the impact of electronic waste on the environment. This commitment to sustainability reflects the company's ethos of responsible and ethical business practices.The unveiling of the double sided circuit board has generated significant interest within the electronics industry. With its potential to revolutionize the way electronic devices are designed and manufactured, industry experts and professionals are eager to see how this technology will shape the future of electronics.In a statement, [Company Name] expressed their enthusiasm for the potential impact of the double sided circuit board: "We are incredibly excited to introduce this groundbreaking technology to the market. The development of the double sided circuit board represents a major milestone for our company and a significant advancement for the electronics industry as a whole. We believe that this innovation will open up new possibilities for the design and manufacturing of electronic devices, and we are committed to working with our partners and customers to realize the full potential of this technology."As the world of electronics continues to evolve, [Company Name] remains at the forefront of innovation. With the unveiling of the double sided circuit board, the company has once again demonstrated its ability to push the boundaries of what is possible in the world of electronic components. This latest development is a testament to their dedication to excellence and their commitment to delivering solutions that meet the evolving needs of the industry.

Custom Bare Printed Circuit Board Manufacturing Services

Bare PCB, a leading provider of high-quality printed circuit boards, has made significant strides in the PCB industry with its cutting-edge technology and innovative approach. The company has been delivering top-notch PCB solutions to a diverse range of industries for over [X] years, earning a solid reputation for its commitment to quality, reliability, and customer satisfaction.Bare PCB specializes in the design, manufacturing, and assembly of a wide variety of PCBs, including single-sided, double-sided, and multi-layer boards. The company's state-of-the-art facility is equipped with the latest machinery and technology, allowing for the production of high-quality PCBs that meet the most stringent industry standards. In addition to its advanced manufacturing capabilities, Bare PCB also offers comprehensive PCB prototyping and testing services. This allows clients to test their PCB designs and make any necessary adjustments before moving on to full-scale production. The company's team of experienced engineers and technicians work closely with clients to ensure that their specific requirements and specifications are met, resulting in PCB solutions that are tailored to their unique needs.Bare PCB takes great pride in its commitment to quality and reliability. The company follows strict quality control processes at every stage of the production process, from the selection of raw materials to the final inspection of finished PCBs. This dedication to quality has earned Bare PCB numerous certifications and accolades, solidifying its position as a trusted and reliable partner in the PCB industry.Despite its already impressive track record, Bare PCB continues to push the boundaries of innovation in the PCB industry. The company invests heavily in research and development, constantly seeking new and improved manufacturing techniques and technologies. This forward-thinking approach ensures that Bare PCB remains at the forefront of the industry, offering its clients the most advanced and cutting-edge PCB solutions available.One of the company's recent developments has been the introduction of environmentally friendly PCB manufacturing processes. Bare PCB has made significant investments in eco-friendly technologies and practices, ensuring that its manufacturing processes have minimal impact on the environment. This commitment to sustainability has not only earned Bare PCB praise from environmental advocates but has also positioned the company as a leader in the industry's movement towards greener manufacturing practices.Moreover, Bare PCB is known for its exceptional customer service and support. The company's dedicated team of professionals is always available to assist clients with any technical questions or concerns they may have. Whether it's providing guidance on PCB design and manufacturing or offering post-sales support, Bare PCB is committed to ensuring that its clients have a positive and seamless experience at every step of the process.In response to the ever-growing demand for high-quality PCB solutions, Bare PCB has expanded its reach to cater to a global clientele. The company now serves customers in [X] countries, providing its top-notch PCB solutions to a wide range of industries, including telecommunications, automotive, aerospace, consumer electronics, and more. This global presence has further cemented Bare PCB's reputation as a leading player in the international PCB market.As Bare PCB continues to grow and innovate, the company remains dedicated to its core values of quality, reliability, and customer satisfaction. With its cutting-edge technology, commitment to sustainability, and exceptional customer service, Bare PCB is well-positioned to meet the evolving needs of the PCB industry and its clients for many years to come.

Top 10 PCB Manufacturing Capabilities You Need to Know

The demand for high-quality printed circuit boards (PCBs) is on the rise, and companies are constantly seeking out manufacturers with the capabilities to meet their specific needs. One company that has been making strides in this area is {}, a leading manufacturer of PCBs. With state-of-the-art facilities and a commitment to delivering exceptional products, {} has established itself as a trusted partner for companies in need of reliable PCB solutions.{} offers a wide range of PCB capabilities, including the ability to produce single-sided, double-sided, and multilayer boards. This flexibility allows customers to select the type of board that best suits their requirements, whether they need a simple, cost-effective solution or a more complex, high-performance board. In addition, {} is able to produce PCBs in a variety of materials, such as FR-4, Rogers, and aluminum, giving customers the freedom to choose the material that best aligns with their project specifications.One of the key strengths of {} is its ability to provide quick turn PCB manufacturing. This means that customers can expect fast turnaround times without compromising on quality. This is especially valuable for companies working on tight deadlines or in fast-paced industries where time-to-market is crucial. {}'s efficient manufacturing process and dedication to meeting deadlines has earned the company a reputation for reliability and responsiveness.In addition to its manufacturing capabilities, {} also offers a range of PCB assembly services. This includes surface mount technology (SMT) and through-hole technology (THT) assembly, as well as testing and quality assurance processes to ensure that the final product meets the highest standards. By offering these assembly services, {} is able to provide customers with a complete PCB solution, from initial design to final assembly, all under one roof.With a focus on quality and precision, {} is committed to delivering PCBs that meet the strictest industry standards. The company's manufacturing processes adhere to ISO 9001 and ISO 14001 certifications, demonstrating its dedication to quality management and environmental responsibility. By prioritizing quality control at every stage of the production process, {} ensures that its customers receive PCBs that are reliable, durable, and consistent in performance.Despite the challenges posed by the COVID-19 pandemic, {} has continued to invest in its manufacturing capabilities, with a focus on automation and digitalization. By leveraging advanced technology and equipment, {} has enhanced its production efficiency and improved its ability to meet the evolving needs of its customers. This ongoing commitment to innovation and improvement has allowed {} to stay at the forefront of the PCB manufacturing industry.As a company, {} prides itself on its customer-centric approach and its ability to provide personalized solutions to meet the unique needs of its clients. With a team of experienced engineers and technical experts, {} offers comprehensive support and guidance throughout the entire manufacturing process. From design assistance to technical troubleshooting, {} is dedicated to ensuring that its customers' PCB requirements are met with the highest level of expertise and professionalism.In conclusion, the PCB capabilities offered by {} make it a standout choice for companies seeking high-quality, reliable printed circuit boards. By combining advanced manufacturing facilities, a commitment to quality, and a customer-focused approach, {} has solidified its position as a leading provider of PCB solutions. As the demand for innovative and high-performance PCBs continues to grow, {} is well-equipped to meet the needs of a diverse range of industries and applications.