How to Prototype and Manufacture PCBs for Your Next Project

By:Admin

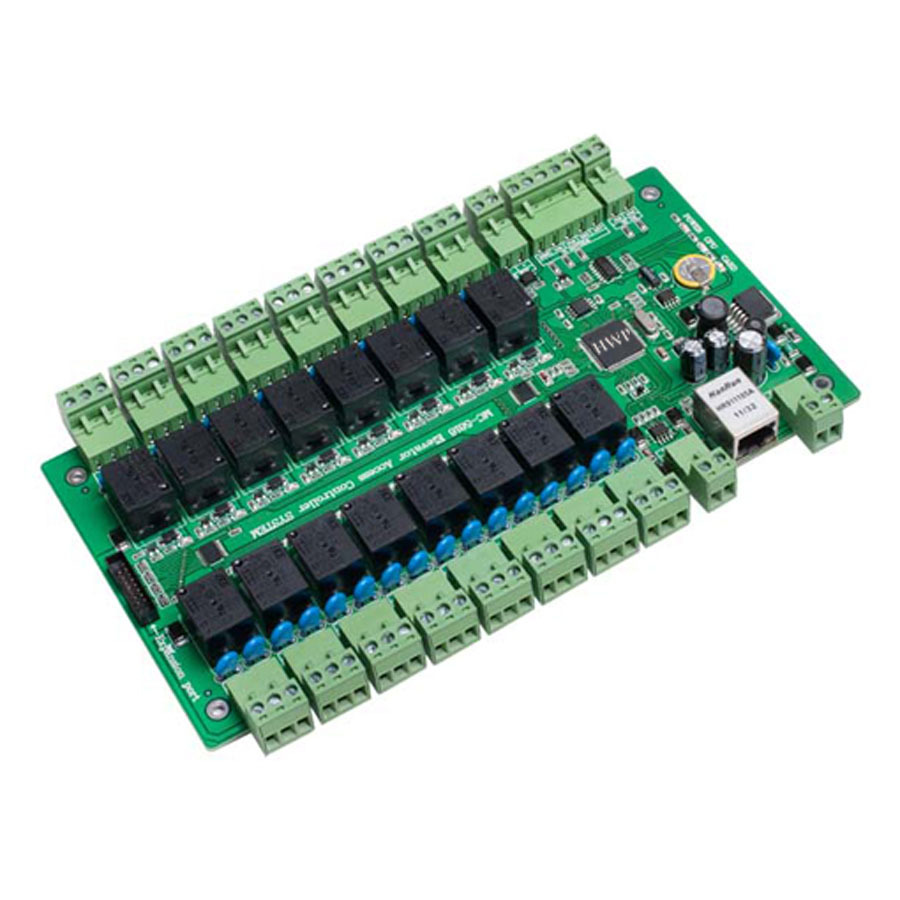

The Prototyp PCB is designed to meet the diverse needs of electronic engineers, hobbyists, and businesses looking to develop new electronic products. With its high-quality materials and precise manufacturing process, the Prototyp PCB ensures reliable performance and durability. The product is also known for its fast turnaround time, making it ideal for prototyping and testing new electronic designs.

One of the key features of the Prototyp PCB is its versatility. The product supports a wide range of applications, including consumer electronics, automotive systems, medical devices, industrial equipment, and more. This flexibility makes it an excellent choice for engineers and designers working on various projects in different industries.

In addition to its versatility, the Prototyp PCB offers excellent performance and functionality. The product is engineered to deliver high-speed data processing, low power consumption, and strong signal integrity, ensuring that electronic devices built with this PCB prototype will perform efficiently and reliably.

[Company Name] has a proven track record of delivering high-quality electronic components and PCB prototypes to its customers. The company's team of expert engineers and technicians are dedicated to providing top-notch products and exceptional customer service. With state-of-the-art facilities and advanced manufacturing capabilities, [Company Name] is able to produce the Prototyp PCB with strict quality control measures in place, ensuring that each prototype meets the highest standards of excellence.

The launch of the Prototyp PCB demonstrates [Company Name]'s commitment to innovation and continuous improvement. The company is dedicated to staying at the forefront of technology and offering cutting-edge solutions to meet the evolving needs of the electronics industry. By investing in research and development, [Company Name] is able to develop products like the Prototyp PCB that push the boundaries of what is possible in electronic design and manufacturing.

Customers who choose the Prototyp PCB can expect to benefit from its high performance, reliability, and cost-effectiveness. The product's competitive pricing and quick turnaround time make it a practical choice for businesses and individuals looking to bring their electronic designs to life. With the Prototyp PCB, customers can save time and money without compromising on quality.

As the electronics industry continues to evolve, [Company Name] remains committed to providing innovative solutions that empower engineers, designers, and businesses to bring their electronic innovations to market. The Prototyp PCB is the latest example of [Company Name]'s dedication to supporting the success of its customers and shaping the future of electronic design and manufacturing.

In conclusion, the launch of the Prototyp PCB represents a significant milestone for [Company Name] and the electronics industry as a whole. The product's advanced features, versatile applications, and reliable performance make it an exceptional choice for anyone looking to prototype and test electronic designs. With [Company Name]'s commitment to quality and innovation, the Prototyp PCB is set to make a lasting impact on the electronic industry and empower customers to achieve their electronic design goals.

Company News & Blog

Efficient Assembly Line Layout Tactics Boost Productivity and Workflow

Assembly Line Layout Revolutionizes Manufacturing Process, Boosting Efficiency and ProductivityIn the competitive world of manufacturing, companies are constantly seeking innovative solutions to enhance their production processes. One groundbreaking approach that has recently gained significant attention is the Assembly Line Layout. This revolutionary concept has the power to transform the manufacturing industry, revolutionizing how products are made and ultimately improving efficiency, productivity, and profitability.Assembly Line Layout, or ALL, is a systematic arrangement of workstations and equipment that allows for a smooth and efficient flow of work from start to finish. It is designed to maximize efficiency by minimizing unnecessary movements, reducing assembly time, and streamlining the entire manufacturing process.By carefully organizing workstations in a sequential order, the Assembly Line Layout eliminates unnecessary backtracking and reduces travel time, resulting in a significant reduction in production time. This arrangement ensures that workers and materials are efficiently utilized and that the production line operates at its maximum potential.With the implementation of ALL, manufacturers can streamline their operations, reduce bottlenecks, and increase overall productivity. By breaking down the production process into smaller tasks, each worker becomes specialized in their assigned task, leading to improved proficiency and speed. This specialization allows for better control over quality, as workers can focus on perfecting their specific task rather than being overwhelmed by multiple responsibilities.One major advantage of the Assembly Line Layout is its scalability. As production demands fluctuate, manufacturers can easily adjust the number of workstations and workers according to their needs. This flexibility allows companies to rapidly adopt changes in demand, ensuring that production keeps pace with market requirements without compromising efficiency or quality.Moreover, the ALL concept promotes standardization, leading to increased product consistency and quality control. With predefined workstations and equipment setups, manufacturers can establish standardized procedures for each task, reducing the risk of human error and ensuring that products meet the highest quality standards. This not only improves customer satisfaction but also reduces costs associated with defective products and rework.The benefits of the Assembly Line Layout extend beyond the manufacturing floor. By optimizing the production process, manufacturers can decrease lead times and deliver products to market faster. This improved time-to-market enables companies to meet customer demands promptly, gain a competitive edge, and capitalize on market opportunities.In addition to the efficiency gains, the Assembly Line Layout facilitates better workflow management. With a clear visual representation of the production process and the ability to monitor progress at each workstation, managers can easily identify bottlenecks and address them proactively. This real-time information empowers decision-makers to make data-driven decisions, optimize resource allocation, and improve overall operational performance.While the Assembly Line Layout offers undeniable advantages, its successful implementation requires careful planning and consideration. Manufacturers must analyze their production requirements, assess the suitability of their product for an assembly line setup, and invest in appropriate equipment and training for their workforce. Additionally, companies must ensure that safety measures are in place to protect workers and prevent accidents in the fast-paced environment of an assembly line.As the manufacturing landscape becomes increasingly competitive, companies must explore innovative solutions to stay ahead. The Assembly Line Layout presents a compelling opportunity for manufacturers to optimize their operations, enhance productivity, and improve profitability. By adopting this revolutionary approach, manufacturers can pave the way for a more efficient and successful future in an ever-evolving industry.

How to Prototype and Manufacture PCBs for Your Next Project

[Company Name], a leading manufacturer of electronic components and PCB (Printed Circuit Board) prototypes, has announced the launch of their latest product, the Prototyp PCB. This cutting-edge PCB prototype offers innovative features and advanced technology that set it apart from other products on the market.The Prototyp PCB is designed to meet the diverse needs of electronic engineers, hobbyists, and businesses looking to develop new electronic products. With its high-quality materials and precise manufacturing process, the Prototyp PCB ensures reliable performance and durability. The product is also known for its fast turnaround time, making it ideal for prototyping and testing new electronic designs.One of the key features of the Prototyp PCB is its versatility. The product supports a wide range of applications, including consumer electronics, automotive systems, medical devices, industrial equipment, and more. This flexibility makes it an excellent choice for engineers and designers working on various projects in different industries.In addition to its versatility, the Prototyp PCB offers excellent performance and functionality. The product is engineered to deliver high-speed data processing, low power consumption, and strong signal integrity, ensuring that electronic devices built with this PCB prototype will perform efficiently and reliably.[Company Name] has a proven track record of delivering high-quality electronic components and PCB prototypes to its customers. The company's team of expert engineers and technicians are dedicated to providing top-notch products and exceptional customer service. With state-of-the-art facilities and advanced manufacturing capabilities, [Company Name] is able to produce the Prototyp PCB with strict quality control measures in place, ensuring that each prototype meets the highest standards of excellence.The launch of the Prototyp PCB demonstrates [Company Name]'s commitment to innovation and continuous improvement. The company is dedicated to staying at the forefront of technology and offering cutting-edge solutions to meet the evolving needs of the electronics industry. By investing in research and development, [Company Name] is able to develop products like the Prototyp PCB that push the boundaries of what is possible in electronic design and manufacturing.Customers who choose the Prototyp PCB can expect to benefit from its high performance, reliability, and cost-effectiveness. The product's competitive pricing and quick turnaround time make it a practical choice for businesses and individuals looking to bring their electronic designs to life. With the Prototyp PCB, customers can save time and money without compromising on quality.As the electronics industry continues to evolve, [Company Name] remains committed to providing innovative solutions that empower engineers, designers, and businesses to bring their electronic innovations to market. The Prototyp PCB is the latest example of [Company Name]'s dedication to supporting the success of its customers and shaping the future of electronic design and manufacturing.In conclusion, the launch of the Prototyp PCB represents a significant milestone for [Company Name] and the electronics industry as a whole. The product's advanced features, versatile applications, and reliable performance make it an exceptional choice for anyone looking to prototype and test electronic designs. With [Company Name]'s commitment to quality and innovation, the Prototyp PCB is set to make a lasting impact on the electronic industry and empower customers to achieve their electronic design goals.

Leading Electronics Supplier Launches Innovative Flexible Printed Circuits

Fpc Electronics Acquires Technology Company to Strengthen Its Capabilities in the Electronics IndustryLeading electronics manufacturer, Fpc Electronics, announced today that they have acquired a technology company in order to enhance their capabilities in the electronics industry. The acquisition will enable Fpc Electronics to expand their product offerings and grow their market share.The name of the technology company was not disclosed, but Fpc Electronics stated that the acquisition was a strategic move to improve their position in the market. The acquisition will help Fpc Electronics to accelerate their innovation and bring new products to market faster.Fpc Electronics is a leading manufacturer of flexible printed circuits (FPC) and rigid-flex circuits. With over 15 years of experience in the industry, Fpc Electronics has become a trusted partner for customers across a variety of industries, including automotive, medical, and telecommunications.“We are very excited about this acquisition and what it means for our company,” said the CEO of Fpc Electronics. “The technology company we acquired has a strong reputation for innovation and has developed some impressive new technologies that will help us to improve our products and services.”The acquisition will also help Fpc Electronics to expand their manufacturing capabilities. The technology company has state-of-the-art manufacturing facilities that will enable Fpc Electronics to increase production and improve efficiency. This will ultimately help Fpc Electronics to better serve their customers and meet the growing demand for their products.“With this acquisition, we are positioning ourselves for continued growth and success in the electronics industry,” added the CEO. “We believe that the combination of our expertise in FPC and rigid-flex circuits, along with the new technologies that we have acquired, will enable us to provide our customers with even more value.”Fpc Electronics has been a pioneer in the electronics industry, introducing new technologies and products that have helped to shape the industry. With this acquisition, Fpc Electronics is once again demonstrating their commitment to innovation and their dedication to meeting the needs of their customers.“We are proud to be a leader in the electronics industry and we are excited about the future of our company,” said the CEO. “We believe that this acquisition will help us to achieve even greater success in the years ahead.”The acquisition is expected to be completed by the end of the year, subject to regulatory approvals. Following the completion of the acquisition, Fpc Electronics will begin integrating the new technologies into their products and services. They will also work to increase production capabilities and improve efficiency in their manufacturing processes.Overall, this acquisition is a significant milestone for Fpc Electronics and a positive development for the electronics industry. With this acquisition, Fpc Electronics is well positioned to continue driving innovation, expanding their market share, and delivering value to their customers.

Understanding the Key Benefits of Electronic PCB Assembly for Efficient Product Integration

Title: Electronic PCB Assembly Company, a Pioneer in Advanced Manufacturing Technologies, Sets New Industry StandardsSubtitle: Positioned at the Forefront of Revolutionary PCB Assembly Solutions, Company Remains Committed to Delivering Cutting-Edge Electronic Products[City, Date] - Electronic PCB Assembly Company, a renowned leader in the electronics manufacturing industry, has been setting new benchmarks with its advanced PCB assembly technologies. With a strong emphasis on innovation, quality, and customer satisfaction, the company has consistently positioned itself as a pioneer in delivering state-of-the-art electronic products to businesses across various sectors.Founded with the vision to revolutionize the electronics industry, Electronic PCB Assembly Company has become synonymous with cutting-edge manufacturing solutions and superior customer service. With a relentless drive for innovation and an unwavering commitment to excellence, the company has rapidly established itself as an industry leader.Electronic PCB Assembly Company specializes in providing comprehensive electronic manufacturing services (EMS), catering to businesses ranging from startups to multinational corporations. The company's expertise lies in the assembly of printed circuit boards (PCBs), which serve as the cornerstone for various electronic devices.Utilizing the latest technologies and adhering to stringent quality control measures, Electronic PCB Assembly Company delivers reliable and high-performing PCBs that meet the unique requirements of its diverse clientele. By employing advanced equipment, efficient processes, and highly skilled professionals, the company ensures the production of top-notch circuit boards that exhibit exceptional performance and durability.Moreover, Electronic PCB Assembly Company understands the importance of staying ahead in a dynamic and rapidly changing industry. The company invests extensively in research and development to stay at the forefront of emerging technologies. This commitment to innovation enables the company to offer innovative assembly solutions, designed to meet the challenges of tomorrow's electronic products.One of the key factors contributing to Electronic PCB Assembly Company's success is its customer-centric approach. The company strives to build long-term partnerships with its clients by understanding their specific needs and providing tailored solutions. By closely collaborating with customers throughout the development and production process, Electronic PCB Assembly Company ensures complete transparency and delivers products that meet and exceed expectations.The company's dedication to quality is evident through its adherence to industry-leading certifications and standards. Electronic PCB Assembly Company follows strict manufacturing protocols, including ISO 9001:2015 and IPC-A-610, to guarantee the highest level of quality assurance. These certifications illustrate the company's unwavering commitment to consistently deliver products that meet international quality benchmarks.Furthermore, Electronic PCB Assembly Company is deeply committed to environmental sustainability. The company actively promotes eco-friendly manufacturing practices and complies with global directives aimed at reducing electronic waste. By adopting environmentally conscious approaches, such as proper waste management and responsible disposal processes, Electronic PCB Assembly Company ensures the protection of the environment while contributing to a more sustainable future.In conclusion, Electronic PCB Assembly Company has emerged as a trailblazer in the field of advanced manufacturing technologies. With its innovative approaches, unparalleled expertise, and customer-centric values, the company has successfully set new industry standards. With a firm commitment to quality, innovation, and sustainability, Electronic PCB Assembly Company continues to spearhead the electronics manufacturing industry by delivering cutting-edge electronic products that meet the evolving demands of businesses worldwide.For media inquiries, please contact:[Name][Title][Company Name][Phone number][Email address]About Electronic PCB Assembly Company:Electronic PCB Assembly Company is a leading provider of electronic manufacturing services, specializing in the assembly of printed circuit boards. With a focus on innovation, quality, and customer satisfaction, the company delivers advanced PCB assembly solutions to businesses across diverse industries. Committed to remaining at the forefront of emerging technologies, Electronic PCB Assembly Company remains dedicated to providing cutting-edge electronic products and fostering long-term partnerships with its clients.

Get Complete PCBA Solutions in One Stop

PCBOne-stop Solution Simplifying the Manufacturing ProcessIn today's fast-paced world, technology is advancing at an incredible pace. This is impacting the world on several fronts, including the electronics industry. Companies are now looking for faster and more efficient ways to manufacture electronic goods without compromising quality, reliability, and affordability. One company that is making strides in simplifying the manufacturing process while providing high-quality products is PCBOne-stop Solution.PCBOne-stop Solution was established in 2008 and is headquartered in Shenzhen, China. For over a decade, the company has provided world-class printed circuit board (PCB) solutions and services to a wide range of clients globally. Since then, the company has expanded to other parts of the world, such as North America, Europe, and Asia, catering to clients from different industries like automotive, communications, industrial, medical, aerospace, and Defence.PCBOne-stop Solution provides a comprehensive range of PCB services that caters to the diverse needs of clients. They offer rigid PCBs, flexible PCBs, and rigid-flex PCBs. Clients can choose their preferred material, sizes, thickness, and color for their PCBs. Additionally, the company provides various PCB assembly services ranging from surface mount technology (SMT) assembly, through-hole component insertion, and hand soldering. With years of experience and experts in the PCB industry, PCBOne-stop Solution has the expertise and capability to handle even the most complex PCB projects.Quality is a top priority for PCBOne-stop Solution; the company understands that the success of its clients' products is dependent on the quality of the PCBs. As such, the company has a well-established quality control system that involves monitoring each step of the production process. This includes raw material selection, production, testing, and packaging. The company's quality control team comprises highly skilled professionals who utilize state-of-the-art equipment to test the quality of the PCBs produced. Additionally, the company adheres to international standards, such as IPC-A-600F, IPC-A-610, and UL safety standards, among others.Another attribute that sets PCBOne-stop Solution apart from its competitors is its commitment to providing clients with a one-stop solution. PCB manufacturing can be complicated and involves multiple steps that require different sets of skills. PCBOne-stop Solution understands that clients do not want to engage several companies to get their PCBs manufactured. As such, the company offers a one-stop solution that involves handling the entire PCB manufacturing process, from design to final assembly.The company's one-stop solution includes PCB layout and design, prototyping, PCB fabrication, electronic component procurement, PCB assembly, and testing. This approach helps clients save time and money while ensuring that their PCBs meet the required industry standards and specifications. Additionally, the company has invested in modern equipment and technologies to streamline its operations while ensuring that clients get their projects delivered within the agreed timelines.PCBOne-stop Solution prides itself on being an environmentally conscious company. In ensuring that it minimizes its environmental impact, the company has implemented eco-friendly measures in its operations, such as the use of lead-free materials in the PCB production process. The company also has a waste management system that ensures that all waste generated in its processes is disposed of in an environmentally safe and sustainable manner.In conclusion, PCBOne-stop Solution is a global PCB manufacturing company that has been providing high-quality PCB solutions and services for over a decade. The company's commitment to quality, its one-stop solution approach, and its environmentally conscious operations make PCBOne-stop Solution a top choice for clients looking for a reliable and efficient partner for their PCB manufacturing needs. With the company's state-of-the-art equipment, industry experience, and dedication to customer satisfaction, clients can rest assured that their PCB projects are in competent hands. For more information about PCBOne-stop Solution, visit their website today.

Revolutionary Circuit Board Home Sparks Innovation and Efficiency

Circuit Board Manufacturer Leads the Way in Sustainable Manufacturing PracticesCircuit Board House (CBH) is a leading manufacturer of printed circuit boards that are used in a wide range of applications, including consumer electronics, automotive industry, computer hardware, and power supplies. The company has been providing high-quality PCB solutions to its clients for over two decades. However, what sets CBH apart from other manufacturers is its commitment to sustainability across all facets of its business operations.CBH understands that as a manufacturer, it has a responsibility to minimize its environmental impact and ensure that its operations are socially responsible. Therefore, the company has taken a proactive approach to addressing these issues by implementing several sustainable practices that reduce waste and improve efficiency.One of the key areas where CBH has made significant strides is in reducing its energy consumption. The company has invested in the installation of energy-efficient equipment and LED lighting in its facilities. This has resulted in a 20% reduction in electricity consumption, cutting the company's carbon footprint by around 1,000 tons per year. The company also recognizes the importance of water conservation and has implemented measures to reduce water usage in its operations.Another significant area of focus for CBH is waste reduction. The company has developed a comprehensive waste management program that includes recycling and reusing as much waste as possible, which has led to a 35% reduction in waste. For example, the company has implemented a strict inventory control system, reducing the amount of scrap material generated during production.In addition to its internal sustainable practices, CBH is committed to sustainable sourcing. The company has established partnerships with suppliers who share its values and who are committed to ethical and environmentally responsible practices. CBH also takes great pride in its employees, providing them with a safe and healthy workplace, along with a range of development and training opportunities.CBH recognizes that its efforts towards sustainability go beyond improving its own operations and extends towards creating a more sustainable industry. Therefore, it is actively engaged in industry associations and initiatives that promote sustainability. The company has also taken a leadership role in educating its clients on the importance of sustainable practices and how they can play a part in creating a more sustainable future.As a result of its commendable efforts, CBH has received several awards and recognitions for its sustainable practices. For example, the company has been awarded the ISO 14001:2015 certification, which acknowledges its commitment to environmental management.Overall, CBH is a company that understands the critical role that businesses play in creating a sustainable future. It has taken admirable steps towards reducing waste, conserving resources, and promoting sustainable practices both within its operations and throughout the broader industry. As the global demand for sustainable practices continues to grow, more companies could learn from CBH's exceptional practices and emulate its approach towards sustainability.

The Step-by-Step Guide to PCB Assembly Process

With a mission to provide cutting-edge PCB assembly solutions that cater to the needs of businesses across industries, Smt Pcb Assembly Process is proud to offer high-quality PCB assembly services that have received numerous accolades from clients around the world. The company has built a solid reputation for delivering world-class solutions designed to deliver the highest levels of durability, reliability, and performance.At Smt Pcb Assembly Process, quality is the top priority, and the company is committed to providing clients with the most advanced PCB assembly services that meet international standards. The company has invested heavily in the latest technology, tools, and equipment needed to achieve high levels of quality control and monitoring at every stage of the assembly process.One of the key strengths of Smt Pcb Assembly Process is its team of highly experienced professionals, who are committed to ensuring that customers get the best possible service and support. The team comprises industry experts who have many years of experience in PCB design, manufacturing, and assembly, and are always on hand to offer guidance, advice, and solutions to any problems clients encounter during the assembly process.Smt Pcb Assembly Process's PCB Assembly process is designed to cater to a wide range of clients, from small startups to large multinationals. The company's capabilities include the assembly of prototypes, low volume production, and high-volume production runs from 100,000 to 10 million units. With a diverse range of clients across various industries, Smt Pcb Assembly Process's team of experts has amassed an in-depth knowledge of the assembly processes involved in the production of complex projects involving printed circuit boards.Smt Pcb Assembly Process has invested in state-of-the-art equipment that enables it to produce PCB designs faster and more precisely than ever before. The company's assembly line features cutting-edge tools, including SMT placement machines, automatic optical inspection machines, and reflow ovens that ensure consistent, high-quality assembly.One of the unique features of Smt Pcb Assembly Process is its advanced testing process to detect faults in PCBs before they are shipped to clients. The company has developed a range of testing methods, including the use of In-circuit Testing (ICT) and Flying Probe testing, that ensure that all PCBs meet the highest standards of quality control.Despite its advanced capabilities and reputation for delivering high-quality PCB assembly services, Smt Pcb Assembly Process is committed to providing cost-effective solutions to its clients. The company has optimized its processes to minimize operational costs while ensuring that quality is never compromised. This enables clients to get the best possible quality at the best possible prices.In conclusion, Smt Pcb Assembly Process is a reputable PCB assembly services provider that stands out for its commitment to quality, speed, and reliability. The company's advanced assembly capabilities, cutting-edge tools, and experienced team of professionals make it a top choice for businesses across industries looking to produce high-quality printed circuit boards. With a focus on customer satisfaction and cost-effectiveness, Smt Pcb Assembly Process is poised to continue delivering world-class PCB assembly services to clients around the world.

Top 5 Tips for SMT PCB Assembly to Improve Efficiency and Quality

SMD PCB Assembly: Revolutionizing Electronic ManufacturingIn today's fast-paced world, the demand for high-quality, efficient electronic devices is constantly on the rise. This increasing demand has led to the need for advanced manufacturing processes that can produce reliable, high-performance electronic products at a rapid pace. One such process that has been revolutionizing the electronic manufacturing industry is Surface Mount Device (SMD) PCB Assembly. SMD PCB Assembly is a method of electronic component mounting on printed circuit boards (PCBs) that has replaced the traditional through-hole technology in many applications. This advanced assembly technique involves mounting electronic components directly onto the surface of the PCB, as opposed to inserting them through holes in the board. This method offers several advantages over through-hole technology, including smaller size, lighter weight, and improved performance.The rapid growth of the electronics industry has led to an increased demand for SMD PCB Assembly services. This is where {} comes into play. As a leading provider of electronic manufacturing services, {} offers top-of-the-line SMD PCB Assembly solutions that are tailored to meet the specific needs of their clients. With state-of-the-art facilities and a team of experienced professionals, {} is well-equipped to handle the most complex SMD PCB Assembly projects with precision and efficiency.{} has established itself as a trusted partner for companies looking to outsource their electronic manufacturing needs. The company's commitment to quality, reliability, and customer satisfaction sets them apart in the highly competitive electronic manufacturing industry. Their SMD PCB Assembly services are designed to streamline the production process, reduce costs, and improve time-to-market for their clients' electronic products.One of the key advantages of SMD PCB Assembly is its ability to accommodate smaller and lighter electronic components. This makes it an ideal choice for the production of compact and portable electronic devices, such as smartphones, tablets, wearables, and IoT devices. With the increasing demand for smaller and more powerful electronic products, SMD PCB Assembly has become an essential manufacturing process for companies looking to stay ahead in the rapidly evolving electronics market.In addition to its size and weight advantages, SMD PCB Assembly also offers improved electrical performance. By mounting components directly onto the surface of the PCB, signal paths are shortened, leading to reduced interference and improved signal integrity. This results in electronic products that are more reliable and efficient, meeting the high standards of today's tech-savvy consumers.As the electronics industry continues to evolve, the demand for SMD PCB Assembly services is expected to grow even further. With the expertise and capabilities offered by {}, companies can stay ahead of the curve by leveraging the benefits of SMD PCB Assembly for their electronic manufacturing needs. By partnering with a trusted electronic manufacturing service provider like {}, companies can ensure that their electronic products are produced with the highest level of quality and performance.In conclusion, SMD PCB Assembly has become a game-changer in the electronic manufacturing industry, offering numerous benefits for companies looking to stay competitive in the fast-paced world of electronics. With its compact size, lightweight, and improved performance, SMD PCB Assembly is the go-to manufacturing process for companies looking to produce high-quality electronic products that meet the demands of today's consumers. With {}'s expertise in electronic manufacturing services, companies can take advantage of the full potential of SMD PCB Assembly to bring their electronic products to market with confidence and success.

Unlocking the Potential of Double Sided Circuit Boards

Double-Sided Circuit Board: Revolutionizing Electronics ManufacturingWith the rapid growth of the electronics industry, manufacturers are constantly striving to develop more efficient and innovative technologies. One such technology that has gained significant attention is the Double-Sided Circuit Board (DSCB). This remarkable advancement in circuit board design and production is revolutionizing the way electronic devices are manufactured and has the potential to further accelerate the industry's progress.Traditionally, circuit boards have been single-sided, meaning that all the electronic components and traces were located on one side of the board. Although effective, this design limited the density of components that could be placed on a single board, ultimately restricting the capabilities of electronic devices. However, the emergence of the DSCB overcomes this limitation by providing two sides for component placement, effectively doubling the available space. This innovation allows for a greater number of components to be integrated onto a single board, leading to a more compact and powerful device.The DSCB brings several distinct advantages over its predecessor, enabling electronics manufacturers to create smaller, lighter, and more efficient products. Firstly, the increased component density on the board allows for more compact designs. This is particularly beneficial for portable devices such as smartphones and tablets, where size and weight are key factors. By utilizing a DSCB, manufacturers can reduce the overall dimensions of these devices, making them more portable and convenient for everyday use.Secondly, the DSCB enables better thermal management. As electronic components generate heat during operation, efficient heat dissipation is crucial to maintain the device's performance and longevity. The increased surface area provided by the double-sided design allows for improved heat dissipation, effectively lowering the operating temperature of the device. This not only prevents overheating but also enhances the overall reliability of the electronic device.Furthermore, the DSCB offers greater flexibility in circuit design. With the introduction of two sides, manufacturers have more space to route traces and interconnect components. This allows for more complex circuit designs, enabling the integration of advanced functionalities and features. As a result, electronic devices equipped with DSCBs have improved capabilities, delivering enhanced performance to end-users.In addition to these benefits, the DSCB also simplifies the assembly and manufacturing processes. By utilizing the two sides of the board, manufacturers can reduce layer count, leading to lower material and manufacturing costs. Moreover, the simplified assembly process minimizes the risk of human error, increasing the overall productivity of the manufacturing line.One company at the forefront of DSCB development is [Company Name]. With its cutting-edge technology and expertise in circuit board design, the company is setting new industry standards. Their state-of-the-art manufacturing facilities have successfully integrated the DSCB into their production lines, enabling them to offer superior quality circuit boards to their clients. By collaborating with various electronics manufacturers, [Company Name] has played a pivotal role in accelerating the adoption of this technology and driving advancements in the electronics industry.Looking ahead, the prospects for the DSCB technology are incredibly promising. As electronics continue to evolve and become more complex, the demand for more efficient and compact designs will only increase. The DSCB provides a robust solution to address these demands, unlocking new possibilities in various sectors such as consumer electronics, automotive, medical devices, and more.As the electronics industry continues to progress, it is vital for manufacturers to embrace innovative technologies like the DSCB. By doing so, they can stay ahead of the competition, deliver cutting-edge products to consumers, and contribute to the overall advancement of the industry. With [Company Name] leading the way, the future of electronic manufacturing looks brighter than ever before.

Revealing the Latest Advancements in Electronics SMT Technology

Electronics SMT: Revolutionizing the Future of Assembly LinesIn today's rapidly evolving technological landscape, automation and precision are key factors that determine the success of manufacturing companies. As such, Electronics SMT, a leading provider of cutting-edge surface-mount technology solutions, has emerged as a powerhouse in the industry. Renowned for its innovative approach and commitment to driving efficiency, Electronics SMT is revolutionizing assembly lines worldwide.Headquartered in [location], Electronics SMT has been at the forefront of surface-mount technology since its inception in [year]. With a diverse portfolio of products and services, the company caters to a wide range of industries, including telecommunications, automotive, aerospace, and consumer electronics.One of the key elements that distinguishes Electronics SMT is its focus on automation. By integrating advanced robotics and artificial intelligence, the company has developed a suite of solutions that significantly streamline the production process. With the ability to handle complex operations with speed and precision, Electronics SMT's automated assembly lines have become the go-to choice for manufacturers seeking enhanced productivity and quality.Central to Electronics SMT's success is its commitment to research and development. The company boasts a team of highly skilled engineers and technicians who work tirelessly to design and improve its surface-mount technology solutions. By staying ahead of the curve when it comes to industry trends, Electronics SMT ensures that its customers benefit from the latest advancements in assembly line technology.Furthermore, Electronics SMT places great emphasis on environmental sustainability. Recognizing the need to minimize its carbon footprint and reduce waste, the company has integrated eco-friendly practices into its production processes. By optimizing material usage and implementing energy-efficient solutions, Electronics SMT ensures that its operations are both cost-effective and environmentally responsible.In addition to its commitment to innovation and sustainability, Electronics SMT also prioritizes customer satisfaction. The company's dedicated support team works closely with clients to understand their specific requirements and deliver tailor-made solutions. Whether it's designing a complete assembly line from scratch or providing on-site training and technical guidance, Electronics SMT goes above and beyond to ensure customer success.One of Electronics SMT's standout products is its state-of-the-art Pick-and-Place machine. Utilizing advanced robotics and computer vision technology, this automated system can accurately place surface-mount components on circuit boards at a remarkable speed. With superior accuracy and efficiency, the Pick-and-Place machine has revolutionized the assembly line landscape, enabling manufacturers to produce high-quality products in a shorter timeframe.Additionally, Electronics SMT offers a wide range of other surface-mount technology solutions, including soldering equipment, inspection systems, and component storage solutions. Each product is meticulously designed to address the specific challenges faced by manufacturers, making Electronics SMT a trusted partner in the industry.Looking ahead, Electronics SMT remains committed to pushing the boundaries of what is possible in surface-mount technology. With ongoing investments in research and development and a customer-centric approach, the company is set to continue driving innovation and efficiency in assembly lines across the globe.In conclusion, Electronics SMT has cemented its position as an industry leader in surface-mount technology. By leveraging automation, sustainability, and a focus on customer satisfaction, the company has reshaped the manufacturing landscape. With its cutting-edge solutions, Electronics SMT is not just revolutionizing assembly lines, but also shaping the future of technology itself.