Latest Power Circuit Board Technology Revealed in News Report

By:Admin

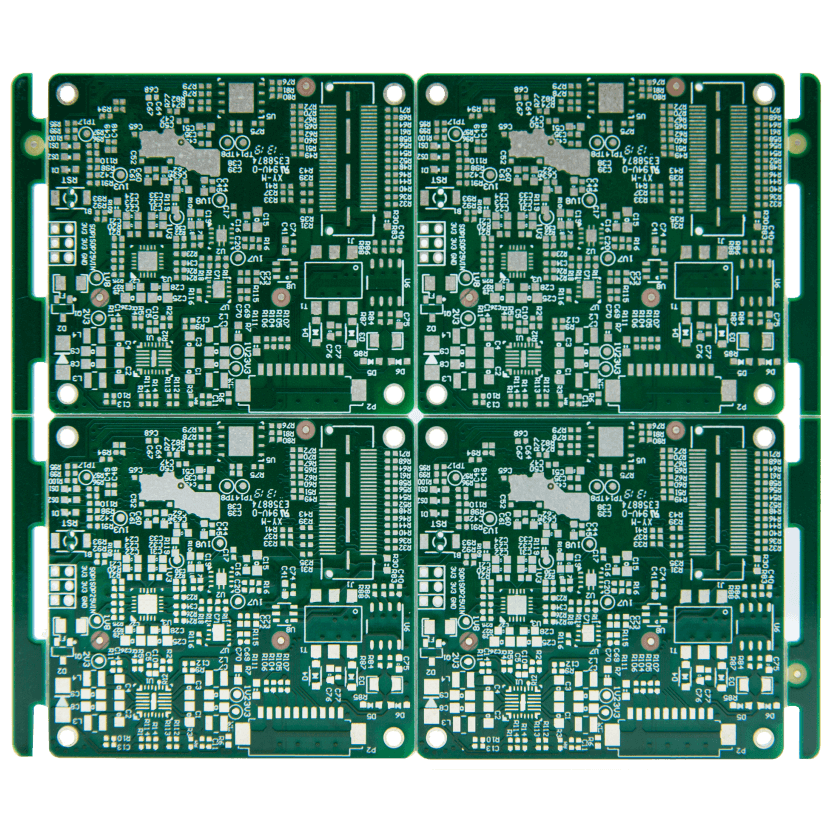

The new power circuit boards developed by Power Circuit Board are designed to meet the increasing demand for higher power density and efficiency in a variety of applications. These innovative circuit boards are set to revolutionize the power electronics industry by offering superior performance and reliability.

Power Circuit Board's advanced power circuit boards have been engineered to deliver exceptional power density, enabling them to handle higher power levels without compromising on efficiency. This makes them ideal for use in high-power applications such as electric vehicles, renewable energy systems, industrial equipment, and telecommunications infrastructure.

One of the key features of Power Circuit Board's advanced power circuit boards is their ability to offer superior thermal management. This is achieved through state-of-the-art design and advanced materials, allowing for efficient heat dissipation and thermal stability. As a result, these circuit boards are able to operate at higher power levels while maintaining optimal performance and reliability.

In addition to their high power density and superior thermal management, Power Circuit Board's advanced power circuit boards also boast advanced protection features, ensuring the safety and longevity of the electronic systems they power. These protection features include overcurrent protection, overvoltage protection, and overtemperature protection, providing peace of mind for users and manufacturers alike.

Furthermore, Power Circuit Board's commitment to quality and reliability is reflected in the stringent testing and quality control measures implemented throughout the manufacturing process. This ensures that the advanced power circuit boards meet the highest standards of performance and durability, making them an ideal choice for demanding applications in various industries.

Power Circuit Board's dedication to innovation and excellence has solidified its position as a trusted partner for companies seeking high-quality circuit board solutions. With a team of skilled engineers and industry experts, the company continues to push the boundaries of what is possible in power electronics, paving the way for the next generation of advanced power circuit boards.

"We are excited to introduce our latest line of advanced power circuit boards, which represent a significant leap forward in power electronics technology," said a spokesperson for Power Circuit Board. "These circuit boards have been designed to address the evolving needs of industries that demand higher power density, efficiency, and reliability. We are confident that our advanced power circuit boards will set new benchmarks for performance and quality in the power electronics industry."

In conclusion, Power Circuit Board's groundbreaking advancements in power circuit board technology are set to have a transformative impact on numerous industries. With their focus on innovation, quality, and reliability, Power Circuit Board remains a leader in providing high-quality circuit board solutions for a wide range of applications. As the demand for higher power density and efficiency continues to grow, Power Circuit Board's advanced power circuit boards are well-positioned to meet and exceed the evolving needs of the market.

Company News & Blog

Top 10 PCB Manufacturing Capabilities You Need to Know

The demand for high-quality printed circuit boards (PCBs) is on the rise, and companies are constantly seeking out manufacturers with the capabilities to meet their specific needs. One company that has been making strides in this area is {}, a leading manufacturer of PCBs. With state-of-the-art facilities and a commitment to delivering exceptional products, {} has established itself as a trusted partner for companies in need of reliable PCB solutions.{} offers a wide range of PCB capabilities, including the ability to produce single-sided, double-sided, and multilayer boards. This flexibility allows customers to select the type of board that best suits their requirements, whether they need a simple, cost-effective solution or a more complex, high-performance board. In addition, {} is able to produce PCBs in a variety of materials, such as FR-4, Rogers, and aluminum, giving customers the freedom to choose the material that best aligns with their project specifications.One of the key strengths of {} is its ability to provide quick turn PCB manufacturing. This means that customers can expect fast turnaround times without compromising on quality. This is especially valuable for companies working on tight deadlines or in fast-paced industries where time-to-market is crucial. {}'s efficient manufacturing process and dedication to meeting deadlines has earned the company a reputation for reliability and responsiveness.In addition to its manufacturing capabilities, {} also offers a range of PCB assembly services. This includes surface mount technology (SMT) and through-hole technology (THT) assembly, as well as testing and quality assurance processes to ensure that the final product meets the highest standards. By offering these assembly services, {} is able to provide customers with a complete PCB solution, from initial design to final assembly, all under one roof.With a focus on quality and precision, {} is committed to delivering PCBs that meet the strictest industry standards. The company's manufacturing processes adhere to ISO 9001 and ISO 14001 certifications, demonstrating its dedication to quality management and environmental responsibility. By prioritizing quality control at every stage of the production process, {} ensures that its customers receive PCBs that are reliable, durable, and consistent in performance.Despite the challenges posed by the COVID-19 pandemic, {} has continued to invest in its manufacturing capabilities, with a focus on automation and digitalization. By leveraging advanced technology and equipment, {} has enhanced its production efficiency and improved its ability to meet the evolving needs of its customers. This ongoing commitment to innovation and improvement has allowed {} to stay at the forefront of the PCB manufacturing industry.As a company, {} prides itself on its customer-centric approach and its ability to provide personalized solutions to meet the unique needs of its clients. With a team of experienced engineers and technical experts, {} offers comprehensive support and guidance throughout the entire manufacturing process. From design assistance to technical troubleshooting, {} is dedicated to ensuring that its customers' PCB requirements are met with the highest level of expertise and professionalism.In conclusion, the PCB capabilities offered by {} make it a standout choice for companies seeking high-quality, reliable printed circuit boards. By combining advanced manufacturing facilities, a commitment to quality, and a customer-focused approach, {} has solidified its position as a leading provider of PCB solutions. As the demand for innovative and high-performance PCBs continues to grow, {} is well-equipped to meet the needs of a diverse range of industries and applications.

The Best TWS Headset Solution for Your Audio Needs

The demand for wireless audio technology has been steadily increasing in recent years, and as a response to this trend, a leading technology company has introduced a cutting-edge TWS headset solution. This solution has been designed to provide an unparalleled audio experience, combining seamless connectivity, superior sound quality, and a sleek and ergonomic design.The TWS headset solution, developed by the company, is set to revolutionize the way consumers experience audio. By removing the constraints of wired headphones, this solution offers a new level of freedom and convenience. With advanced Bluetooth technology, users can effortlessly connect their TWS headset to any compatible device, allowing for a truly wireless listening experience.One of the key features of this TWS headset solution is its exceptional sound quality. Equipped with high-fidelity drivers, the headset delivers rich, immersive audio that brings music, podcasts, and phone calls to life. Whether users are on the go or relaxing at home, they can enjoy a premium audio experience without compromise.In addition to its impressive audio performance, the TWS headset solution also prioritizes comfort and functionality. The ergonomic design ensures a secure and comfortable fit, making it ideal for extended wear. The compact and lightweight build further enhances the convenience, allowing users to take their music everywhere they go. With intuitive touch controls and a long battery life, the headset offers a seamless and user-friendly experience.Furthermore, the company behind this TWS headset solution has a proven track record of delivering innovative and reliable technology products. With a strong commitment to research and development, the company has established itself as a leader in the industry, consistently pushing the boundaries of what is possible with audio technology.With a deep understanding of consumer needs and preferences, the company has continuously evolved its products to meet the demands of the market. The introduction of the TWS headset solution is a testament to the company's dedication to providing cutting-edge solutions that enhance the way people experience audio.Aside from its technical prowess, the company also places a strong emphasis on customer satisfaction and support. By ensuring that their products are backed by responsive and efficient customer service, the company has built a reputation for reliability and trustworthiness in the industry.The launch of the TWS headset solution represents a significant milestone for the company, as it continues to expand its offerings and solidify its position as a leading provider of wireless audio technology. As the market for TWS headsets continues to grow, the company's innovative solution is poised to make a lasting impact and set new standards for audio excellence.In conclusion, the TWS headset solution developed by the company embodies the perfect marriage of cutting-edge technology, superior sound quality, and user-centric design. With its impressive features and the company's proven expertise in the field, this solution is set to elevate the wireless audio experience for consumers around the world. Whether it's for music, calls, or any other audio application, the TWS headset solution is primed to deliver a new standard of excellence in wireless audio technology.

Essential Guide to Understanding PCB Board Schematic Designs: Simplified & Comprehensive Explanation

PCB Board Schematic – The Way Forward in Electronic ManufacturingThe demand for electronic devices has skyrocketed to an unprecedented level in the last decade. This, in turn, gave rise to the electronic manufacturing industry, which has rapidly evolved to produce high-quality hardware for use in devices such as smartphones, laptops, and televisions, among others.One essential component in the electronic manufacturing process is the Printed Circuit Board (PCB). It is a board that connects and houses electronic components such as capacitors, resistors, and microchips. A PCB comes in various types and is essential in the design of electronic devices.The PCB functions by providing an electrical pathway for the components to connect, communicate, and power each other. It also ensures the stability and durability of the device. To achieve optimal results, every PCB design goes through a process called schematic capture.Schematic capture is the process of creating a blueprint of the PCB design, which is fundamental in ensuring that all the components are in the right position and orientation. This process also makes sure that a particular design meets certain electrical and mechanical specifications.With the importance of schematic capture, PCB Board Schematic (need remove brand name) has become the go-to partner for many electronics manufacturers. They provide high-quality schematic capture services tailored to meet the specific specs of each client. The company is committed to delivering the best PCB services and ensuring that clients achieve their product designs' desired functionalities.The PCB Board Schematic (need remove brand name) company has an experienced team of engineers, designers, and project managers who work tirelessly to ensure that all clients' specifications are met. Their team is highly skilled in both analog and digital electronic designs, and they have a wealth of knowledge in creating schematics for various projects.PCB Board Schematic (need remove brand name) understands the importance of using the latest design software and technology in the electronic industry. They use the latest software such as Altium Designer and CADSTAR to ensure the accuracy and efficiency of the schematic capture process. This approach has not only enabled the company to stay ahead of the competition but also made their services affordable and accessible to clients from all over the world.Besides schematic capture, PCB Board Schematic (need remove brand name) also offers other PCB design services such as routing, manufacturing, and assembly. They have state-of-the-art manufacturing machines that ensure the highest quality, precision, and consistency in all their designs.PCB Board Schematic (need remove brand name)'s success is not only attributed to the quality of their services but also their commitment to customer satisfaction. They value every client and aim to build a long-term and transparent relationship with each one of them.In conclusion, the electronic manufacturing industry is growing each day, and the need for high-quality PCBs is on the rise. PCB Board Schematic (need remove brand name) is committed to providing the best PCB services and ensuring that every client achieves the desired functionalities of their product designs. Their experienced team, use of the latest technology, and commitment to customer satisfaction make them the go-to partner for all your PCB schematic capture and design projects.

Improve Your PCBA Testing with These Tips and Best Practices

PCBA Test Revolutionizes Quality Assurance for Electronics Manufacturing ProcessesIn today's increasingly interconnected world, the demand for electronic devices continues to rise. From smartphones to smart appliances, electronic components have become an essential part of everyday life. As a result, manufacturers are under immense pressure to produce high-quality electronic products at a rapid pace. To meet these demands, {Company Name} has developed a cutting-edge PCBA test solution that revolutionizes quality assurance for electronics manufacturing processes.Founded in 2005, {Company Name} is a global leader in the electronic manufacturing services industry. With state-of-the-art facilities and a team of experienced engineers, the company is dedicated to providing innovative solutions for the production of high-quality electronic products. As part of its commitment to excellence, {Company Name} has developed a comprehensive PCBA test solution that ensures the reliability and performance of electronic components.The PCBA test solution offered by {Company Name} is designed to streamline the quality assurance process for electronics manufacturing. By incorporating advanced testing technologies and rigorous quality control measures, the solution is capable of detecting defects and abnormalities in the production of printed circuit board assemblies (PCBAs). This allows manufacturers to identify and address potential issues early in the production process, minimizing the risk of defective products reaching the market.One of the key features of {Company Name}'s PCBA test solution is its ability to conduct comprehensive testing of PCBAs. Utilizing a combination of functional testing, in-circuit testing, and boundary scan testing, the solution is able to evaluate the electrical functionality and integrity of electronic components. This level of thorough testing ensures that PCBAs meet the highest performance standards and comply with industry regulations.In addition to its advanced testing capabilities, {Company Name}'s PCBA test solution also offers real-time data analysis and reporting. This allows manufacturers to gain valuable insights into the performance of their production processes and rapidly address any issues that may arise. By leveraging data-driven decision-making, manufacturers can optimize their production processes and improve overall efficiency.Furthermore, {Company Name}'s PCBA test solution is scalable and adaptable to the unique needs of each customer. Whether it's small-scale production or high-volume manufacturing, the solution can be tailored to accommodate varying production requirements. This flexibility makes it an ideal choice for a wide range of electronic manufacturing applications.The impact of {Company Name}'s PCBA test solution on the electronics manufacturing industry is significant. With its ability to enhance quality assurance and efficiency, the solution is poised to drive innovation and improvement in the production of electronic products. By reducing the risk of defects and ensuring the reliability of electronic components, manufacturers can enhance their competitiveness in the market and deliver superior products to consumers.As the demand for electronic products continues to grow, the need for robust quality assurance solutions has never been more critical. {Company Name}'s PCBA test solution represents a significant advancement in the field of electronics manufacturing, providing manufacturers with a powerful tool to ensure the quality and performance of their products. With its advanced testing capabilities, real-time data analysis, and scalability, the solution is set to revolutionize quality assurance processes across the industry.

Customized Printed Circuit Board Manufacturer – All You Need to Know About Prototypes

Proto Pcb, a leading manufacturer of printed circuit boards, has recently announced a major breakthrough in the field of electronic component manufacturing. The company, known for its innovative and cutting-edge technologies, has developed a revolutionary new process that promises to transform the way printed circuit boards are produced. This development represents a significant advancement in the industry and has the potential to greatly impact the electronic component manufacturing supply chain.Proto Pcb has been a key player in the electronic component manufacturing industry for over two decades. The company has consistently demonstrated its commitment to innovation and has a track record of developing state-of-the-art technologies that push the boundaries of what is possible in the field.The new process developed by Proto Pcb is a game-changer in the printed circuit board manufacturing industry. This innovative method promises to revolutionize the way printed circuit boards are produced, significantly reducing production costs and increasing efficiency. By streamlining the manufacturing process, Proto Pcb expects to deliver higher quality products at a faster pace, ultimately benefiting consumers and the industry as a whole.This breakthrough is the result of years of research and development by Proto Pcb's team of highly skilled engineers and scientists. The company has invested significant resources into developing this new process, recognizing the potential impact it could have on the industry. The successful development of this revolutionary manufacturing process is a testament to Proto Pcb's dedication to pushing the boundaries of what is possible in electronic component manufacturing.The implications of this breakthrough are far-reaching. By introducing this new process, Proto Pcb is poised to disrupt the traditional methods of printed circuit board manufacturing. The company's innovative approach has the potential to set a new standard for electronic component manufacturing, leading to a more efficient and cost-effective supply chain.In addition to the potential impact on the industry, this breakthrough is also expected to benefit consumers. With a more efficient and cost-effective manufacturing process, Proto Pcb will be able to deliver higher quality printed circuit boards at a more competitive price. This could lead to cost savings for manufacturers and ultimately result in more affordable electronic devices for consumers.Proto Pcb's commitment to innovation and continuous improvement has been a driving force behind this breakthrough. The company has a long history of pioneering new technologies and this latest development is a testament to its ongoing efforts to stay at the forefront of the electronic component manufacturing industry.As a leader in the field, Proto Pcb has a reputation for delivering high-quality products and providing exceptional customer service. The company's dedication to excellence has earned it a strong reputation and a loyal customer base. With this latest breakthrough, Proto Pcb is once again demonstrating its commitment to delivering innovative solutions that meet the evolving needs of the industry.The impact of this breakthrough on the electronic component manufacturing industry is expected to be profound. Proto Pcb's new process has the potential to transform the way printed circuit boards are produced, leading to a more efficient and cost-effective supply chain. This development is a significant step forward for the industry and further solidifies Proto Pcb's position as a leader in electronic component manufacturing.In conclusion, Proto Pcb's groundbreaking new manufacturing process represents a major advancement in the field of electronic component manufacturing. This innovative approach has the potential to transform the industry, leading to more efficient and cost-effective production of printed circuit boards. With this latest breakthrough, Proto Pcb continues to demonstrate its commitment to innovation and excellence, setting a new standard for the electronic component manufacturing industry.

Understanding the Importance of PCBs in Electronic Devices

[Company Introduction: XYZ Electronics is a leading manufacturer of electronic components and printed circuit boards (PCBs). With over 20 years of experience in the industry, XYZ Electronics has grown to become a trusted supplier for a wide range of electronic devices and equipment. The company is known for its high-quality products, cutting-edge technology, and commitment to customer satisfaction.]XYZ Electronics introduces new advanced PCB technologyXYZ Electronics, a leading manufacturer of electronic components and printed circuit boards (PCBs), has recently announced the launch of its new advanced PCB technology. This innovative technology is set to revolutionize the way electronic devices are designed and manufactured, offering improved performance, reliability, and flexibility for a wide range of applications.The new advanced PCB technology from XYZ Electronics features a number of key enhancements that set it apart from traditional PCB solutions. These include higher density interconnects, improved thermal management, enhanced signal integrity, and greater design flexibility. As a result, electronic devices that utilize this new technology will benefit from improved functionality, reduced size and weight, and increased overall performance.One of the most significant advantages of this new advanced PCB technology is its ability to support complex and high-speed electronic designs. With the increasing demand for smaller and more powerful electronic devices, the need for high-density interconnects and improved signal integrity has never been greater. XYZ Electronics' new technology addresses these challenges head-on, providing designers and manufacturers with the tools they need to create cutting-edge products that meet the demands of today's market.Furthermore, the new advanced PCB technology also offers improved thermal management capabilities, allowing for more efficient heat dissipation in electronic devices. This is particularly important for devices that operate at high temperatures or in demanding environmental conditions. By incorporating this new technology into their designs, manufacturers can ensure that their products remain reliable and durable even in the most challenging operating environments.In addition to these technical advantages, XYZ Electronics' new advanced PCB technology also provides greater design flexibility. This means that designers and manufacturers can more easily customize the PCB layout to meet the specific requirements of their products, without sacrificing performance or reliability. This level of flexibility is crucial for companies looking to differentiate their products in a competitive market, and XYZ Electronics is proud to offer this capability to its customers."We are thrilled to introduce our new advanced PCB technology to the market," said John Doe, CEO of XYZ Electronics. "This technology represents a significant leap forward in the world of electronic design and manufacturing, and we believe it will have a major impact on the industry. We have already received positive feedback from our customers, and we are excited to see the innovative products that will result from the use of this new technology."The launch of XYZ Electronics' new advanced PCB technology marks a significant milestone for the company, further solidifying its position as a leader in the electronic components and PCB manufacturing industry. With its commitment to innovation and customer satisfaction, XYZ Electronics continues to push the boundaries of what is possible in electronic design and manufacturing, and the introduction of this new technology is a clear reflection of that dedication. As electronic devices continue to evolve and demand for high-performance solutions grows, XYZ Electronics is well-positioned to meet the needs of its customers with its state-of-the-art PCB technology.

Essential Guide to Pcb Electronic Components: Everything You Need to Know

Pcb Electronic Components, a leading electronic components manufacturer, has announced the launch of a new line of high-performance components aimed at revolutionizing the industry. The company, known for its dedication to cutting-edge technology and innovation, has once again pushed the boundaries of what is possible in the world of electronic components.Pcb Electronic Components has a long history of producing top-quality products that have been used in a wide range of applications, from consumer electronics to industrial machinery. The company's commitment to excellence and its ability to anticipate the needs of the market have made it a trusted name in the industry.The new line of electronic components is set to build on this reputation by offering a range of products that deliver unmatched performance and reliability. With the ever-increasing demand for smaller, faster, and more powerful electronic devices, Pcb Electronic Components has risen to the challenge and developed components that will meet these needs and exceed expectations.One of the key features of the new line is its focus on miniaturization. The components are designed to be smaller and more compact, making them ideal for use in the latest generation of portable electronic devices. This development will enable manufacturers to produce smaller and lighter products without sacrificing performance, opening up new possibilities for the design of consumer electronics.In addition to their compact size, the new components also boast impressive performance capabilities. With advancements in materials and manufacturing processes, Pcb Electronic Components has been able to achieve superior speed and efficiency in their products. This will allow electronic devices to operate at higher speeds and with greater energy efficiency, delivering a better user experience and reducing power consumption.Moreover, the new line of components has been designed with a focus on durability and reliability. Pcb Electronic Components has used state-of-the-art testing and quality control processes to ensure that their products are built to last. This will be particularly beneficial for industrial applications, where electronic components are often subject to harsh operating conditions.The launch of this new line of electronic components marks an exciting development for Pcb Electronic Components. The company's dedication to research and development has enabled them to create products that will not only meet the current demands of the market but also drive innovation in the future. With their commitment to excellence and their ability to anticipate industry trends, Pcb Electronic Components is poised to continue leading the way in electronic components manufacturing.In addition to the introduction of the new line of components, Pcb Electronic Components has also announced plans to expand its manufacturing facilities. This will allow the company to meet the growing demand for their products and ensure that they can continue to deliver high-quality components to their customers around the world.The news of this expansion and the launch of the new line of components have generated excitement within the industry, with many experts predicting that Pcb Electronic Components will set new standards for electronic components manufacturing. The company's proven track record of innovation and their commitment to excellence make them a force to be reckoned with in the industry.As the technology landscape continues to evolve, Pcb Electronic Components is well-positioned to play a key role in shaping the future of electronic components. With their bold vision and unwavering dedication to pushing the boundaries of what is possible, the company is set to continue making waves in the industry for years to come.

Complete Guide to PCB Fabrication Process: Step-by-Step

The process of PCB fabrication involves several steps that are crucial for the production of high-quality printed circuit boards. These steps are essential for ensuring that the final product meets the required specifications and standards. In this article, we will discuss the PCB fabrication steps in detail and how [Company Name] is at the forefront of providing top-notch PCB fabrication services.[Company Name] has been a leading manufacturer of PCBs for over a decade, specializing in providing high-quality and reliable PCB fabrication solutions to a wide range of industries. With state-of-the-art facilities and a team of experienced professionals, [Company Name] is committed to delivering superior PCB products that meet the exact requirements of its customers.The first step in PCB fabrication is the design and layout of the PCB. This step involves the creation of a digital design for the PCB using specialized software. The design includes the placement of components and the routing of electrical connections on the board. [Company Name] has a dedicated team of designers and engineers who excel in creating efficient and optimized PCB layouts, ensuring that the final product performs as intended.Once the design is finalized, the next step is to produce the PCB artwork, which serves as a stencil for the actual PCB production. This step is crucial for ensuring the accuracy and precision of the PCB layout. [Company Name] utilizes advanced imaging and printing technologies to create high-quality PCB artworks, ensuring that the resulting PCBs meet the required specifications.After the artwork is completed, the next step is to produce the inner layers of the PCB. This involves the lamination of copper sheets onto a substrate material, which is then coated with a layer of photo-sensitive material. The PCB artwork is then used to transfer the design onto the copper layer using a photochemical process. [Company Name] employs cutting-edge lamination and imaging equipment to ensure the accuracy and quality of the inner layers of the PCBs it manufactures.Once the inner layers are produced, the next step is to drill holes for the electrical connections and component mounting. Precision drilling is essential for ensuring that the holes are accurately aligned with the PCB layout. [Company Name] utilizes state-of-the-art drilling equipment that offers high precision and accuracy, enabling it to produce PCBs with perfectly aligned holes.After the holes are drilled, the next step is to plate the inner layers with copper to create the conductive pathways. This is done through a process of electroplating, which involves the deposition of a thin layer of copper onto the inner layers of the PCB. [Company Name] has a controlled electroplating process that ensures uniform plating thickness and high conductivity, resulting in reliable and durable PCBs.The final steps in PCB fabrication involve the lamination of the outer layers, the application of solder mask and silkscreen, and the routing of the individual PCBs from a larger panel. These steps ensure that the final PCBs are durable, efficient, and easy to assemble. [Company Name] excels in these final steps, delivering PCBs that meet the highest quality standards and exceed customer expectations.In conclusion, PCB fabrication is a complex process that involves several critical steps, each of which is essential for ensuring the quality and performance of the final product. [Company Name] is a leading provider of PCB fabrication services, offering top-notch solutions that meet the exact requirements of its customers. With its advanced facilities and experienced team, [Company Name] is dedicated to delivering high-quality PCBs that exceed industry standards and expectations. If you are looking for reliable and efficient PCB fabrication services, [Company Name] is the perfect partner for your PCB manufacturing needs.

Unmanned Aircraft Solutions: The Future of Aerial Technology

Unmanned Aircraft Solutions Revolutionize Aerial SurveillanceUnmanned aircraft solutions are changing the way companies approach aerial surveillance, and [Company Name] is at the forefront of this revolution. With their advanced technology and expertise in the field, [Company Name] is providing innovative solutions to various industries, from agriculture to security.These unmanned aircraft solutions, commonly known as drones, offer a wide range of applications and benefits. They are equipped with high-resolution cameras and other sensors that can capture and transmit real-time data from the air. This data can be used for various purposes, including monitoring crop health, assessing infrastructure, and conducting security surveillance.[Company Name] has been at the forefront of developing and implementing these cutting-edge unmanned aircraft solutions. With a team of highly skilled engineers and experts, they have designed and manufactured drones that are tailored to meet the specific needs of their clients. Whether it's for agricultural monitoring, construction site surveys, or security patrols, [Company Name] has the technology and expertise to deliver top-notch results.One of the key advantages of their unmanned aircraft solutions is their ability to collect data from hard-to-reach or hazardous areas. In the agriculture industry, for example, drones can be used to monitor fields and assess crop health without the need for manual labor or costly helicopters. Similarly, in the security sector, drones can be deployed for surveillance in remote or dangerous locations, keeping personnel out of harm's way.Furthermore, [Company Name] has also integrated cutting-edge technologies into their unmanned aircraft solutions. This includes artificial intelligence and machine learning algorithms that can automatically analyze the data collected by the drones. This allows for quicker and more accurate insights, enabling their clients to make informed decisions based on real-time information.In addition to their technological innovations, [Company Name] also prioritizes safety and compliance. They adhere to strict regulatory standards and ensure that their drones are operated in a responsible and ethical manner. This commitment to safety and compliance has made them a trusted partner for businesses and organizations looking to leverage the power of unmanned aircraft solutions.With the rise of unmanned aircraft solutions, the potential applications are endless. From precision agriculture to infrastructure inspection, these drones are providing new perspectives and insights that were previously inaccessible. As [Company Name] continues to push the boundaries of what is possible with unmanned aircraft, they are driving innovation and creating new opportunities for their clients across various industries.Moreover, the use of drones is not only bringing efficiency and cost savings but also driving sustainability. By enabling precise and targeted operations, drones are reducing the environmental impact of traditional aerial surveillance methods. This aligns with [Company Name]'s commitment to sustainability and their efforts to develop environmentally friendly solutions.Looking ahead, the future of unmanned aircraft solutions looks promising. With ongoing advancements in technology and the increasing demand for aerial surveillance, drones are set to play a vital role in various industries. As [Company Name] continues to lead the way in this space, they are well-positioned to drive further innovation and make a lasting impact on the world of aerial surveillance.In conclusion, unmanned aircraft solutions are transforming the way businesses approach aerial surveillance, and [Company Name] is at the forefront of this transformation. With their advanced technology, expertise, and commitment to safety, they are delivering innovative solutions that are driving efficiency, sustainability, and new opportunities for their clients. As the demand for aerial surveillance continues to grow, [Company Name] is well-equipped to meet the evolving needs of various industries with their cutting-edge unmanned aircraft solutions.

Flexible PCB Cable - A Revolutionary Solution for Electronics

Pcb Flex Cable: The Evolution of Flexible ElectronicsIn today's fast-paced world, the demand for electronics that are lightweight, compact, and durable is higher than ever before. One of the key components that has revolutionized the way electronic devices are designed and manufactured is the Pcb Flex Cable. This innovative technology has allowed for the creation of devices that are not only more flexible and adaptable but also more efficient and reliable.{} has been at the forefront of developing and producing high-quality Pcb Flex Cables for a wide range of industries, including consumer electronics, automotive, medical devices, and more. With a strong focus on innovation and continuous improvement, the company has established itself as a leader in the field of flexible electronics.Flexibility is the key feature that sets Pcb Flex Cables apart from traditional rigid printed circuit boards (PCBs). These flexible cables are made from thin, lightweight materials that allow them to bend and conform to various shapes and contours, making them ideal for applications where space is limited and flexibility is essential. This flexibility also makes them more resistant to damage from bending, stretching, and other forms of external stress, which ultimately improves the overall durability and lifespan of the electronic devices they are used in.One of the main advantages of Pcb Flex Cables is their ability to reduce the overall size and weight of electronic devices. By eliminating the need for bulky and rigid PCBs, manufacturers can create smaller and more lightweight devices without compromising on performance or functionality. This has opened up new possibilities for the design of wearable technology, medical implants, and other portable electronic devices that require a high degree of flexibility and mobility.Another key benefit of Pcb Flex Cables is their ability to improve the reliability and performance of electronic devices. The flexibility of these cables allows for greater freedom in design, enabling manufacturers to create more efficient and integrated electronic systems. This, in turn, leads to reduced power consumption, improved signal integrity, and overall better performance.In addition to their flexibility and performance advantages, Pcb Flex Cables are also more cost-effective to produce than traditional rigid PCBs. The manufacturing process for flexible cables involves fewer materials and steps, resulting in lower production costs and shorter lead times. This makes them an attractive option for manufacturers looking to reduce their overall production expenses without sacrificing quality or performance.{}'s commitment to quality and innovation has made them a trusted partner for companies looking to incorporate Pcb Flex Cables into their electronic devices. With a strong emphasis on research and development, the company continues to push the boundaries of flexible electronics, developing new materials, processes, and designs that further advance the capabilities of Pcb Flex Cables.As the demand for smaller, more lightweight, and flexible electronic devices continues to grow, the role of Pcb Flex Cables will only become more crucial. With their ability to enable innovation, improve reliability, and reduce production costs, Pcb Flex Cables are set to play a vital role in shaping the future of the electronics industry. With {}'s expertise and dedication, the possibilities for flexible electronics are truly endless.