The Importance of PCB Manufacturing Services in Today's Electronic Industry

By:Admin

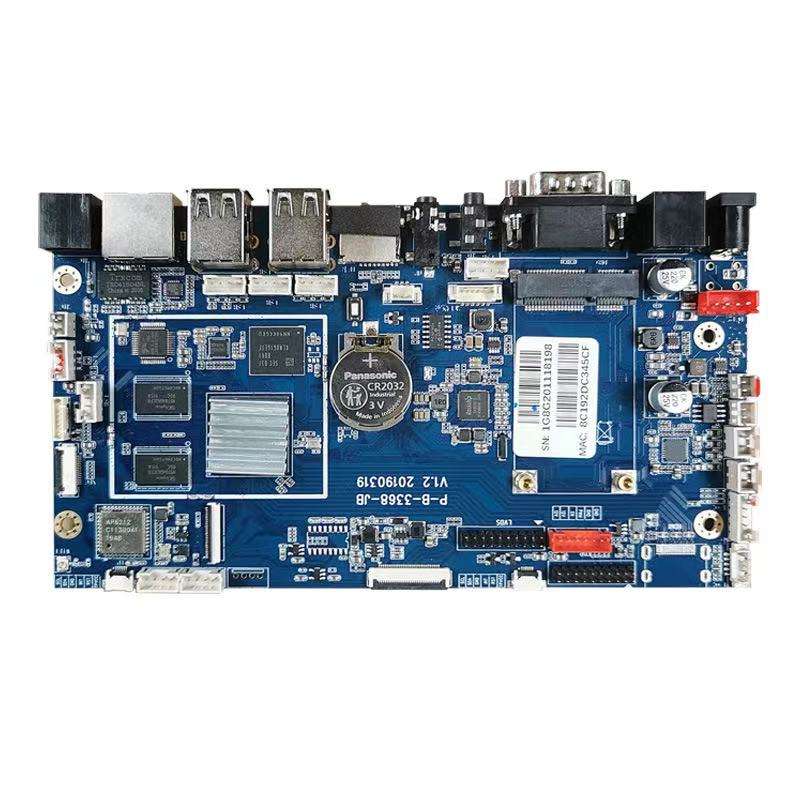

With an extensive history and a solid reputation, (need remove brand name) has established itself as a reliable provider of PCB manufacturing services. The company's commitment to quality, innovation, and customer satisfaction has helped it carve a niche for itself in the competitive market.

As a leading PCB manufacturing service provider, (need remove brand name) offers a wide range of services to cater to the specific requirements of its clients. The company specializes in the production of high-quality, customized PCBs that are designed to meet the unique needs of various industries, including aerospace, telecommunications, automotive, and consumer electronics. With state-of-the-art facilities and a team of experienced professionals, (need remove brand name) is capable of delivering top-notch PCB manufacturing solutions that adhere to the highest industry standards.

One of the key factors that set (need remove brand name) apart from its competitors is its commitment to innovation. The company continuously invests in research and development to stay at the forefront of technological advancements in the PCB manufacturing industry. This dedication to innovation enables (need remove brand name) to offer cutting-edge solutions that are tailored to the evolving needs of its clients.

Furthermore, (need remove brand name) places a strong emphasis on quality control throughout the entire manufacturing process. The company follows stringent quality assurance protocols to ensure that each PCB meets the highest standards of performance and reliability. By leveraging advanced testing methodologies and rigorous inspection processes, (need remove brand name) is able to deliver PCBs that are free from defects and built to last.

In addition to its commitment to quality and innovation, (need remove brand name) takes great pride in its customer-centric approach. The company understands the importance of building strong, long-lasting relationships with its clients, and therefore, places a high value on customer satisfaction. From the initial consultation to final delivery, (need remove brand name) works closely with its clients to understand their unique requirements and provide tailored solutions that exceed their expectations.

With a strong track record of delivering exceptional PCB manufacturing services, (need remove brand name) has earned the trust of numerous clients across various industries. Whether it's a small-scale prototype or a large-scale production run, the company is equipped to handle projects of all sizes with the same level of precision and dedication.

As the demand for high-quality electronic components continues to grow, (need remove brand name) remains committed to pushing the boundaries of PCB manufacturing. By staying at the forefront of technological advancements and maintaining a customer-centric approach, the company is well-positioned to continue its success in the industry.

In conclusion, (need remove brand name) has firmly established itself as a leading provider of PCB manufacturing services, setting a standard for quality, innovation, and customer satisfaction. With a strong emphasis on precision, reliability, and customization, the company has become a trusted partner for clients in need of top-notch PCB solutions. As the industry continues to evolve, (need remove brand name) remains dedicated to meeting the ever-changing needs of its clientele, solidifying its position as a key player in the PCB manufacturing sector.

Company News & Blog

Understanding the Basics of DFM (Design for Manufacturability) in PCB Manufacturing

DFM in PCB (Design for Manufacturing in Printed Circuit Board) is a crucial aspect of the PCB manufacturing process. It ensures that the design of the PCB is optimized for efficient and cost-effective manufacturing. By incorporating DFM principles into the design phase, manufacturers can avoid costly errors and delays during production.{Company Name} is a leading PCB manufacturing company that specializes in producing high-quality and reliable circuit boards for various industries. With state-of-the-art facilities and a team of experienced engineers, they are committed to delivering superior PCB solutions to their customers.Recently, {Company Name} has announced that they have enhanced their DFM capabilities to further improve the quality and efficiency of their PCB manufacturing process. By investing in advanced DFM software and training their engineers on the latest DFM guidelines, {Company Name} aims to streamline their production workflow and deliver even higher quality PCBs to their customers.DFM in PCB involves several key elements, including design optimization, material selection, and process validation. By utilizing DFM software, {Company Name} can analyze the design of the PCB and identify any potential manufacturability issues, such as component placement, trace width, or spacing constraints. This allows them to make necessary adjustments to the design early in the process, reducing the risk of manufacturing errors and ensuring that the final PCB meets performance requirements.In addition, {Company Name} is also focusing on material selection as part of their DFM strategy. By carefully choosing the right materials for each PCB design, they can ensure that the final product meets the necessary performance and reliability standards. This involves considering factors such as thermal properties, signal integrity, and cost-effectiveness to achieve the best possible outcome for their customers.Furthermore, process validation is a critical aspect of DFM in PCB. By simulating the manufacturing process and conducting thorough testing, {Company Name} can identify any potential issues before they arise during production. This proactive approach enables them to address any concerns and make necessary adjustments to the design before manufacturing, ultimately saving time and costs.With these enhancements to their DFM capabilities, {Company Name} is confident that they will be able to offer their customers even better service and products. By incorporating DFM principles into their PCB design process, they are positioning themselves as a reliable and efficient partner for their customers' PCB manufacturing needs."We are committed to providing our customers with the highest quality PCB solutions, and our enhanced DFM capabilities are a testament to that commitment," said [Spokesperson's Name], [Position]. "By investing in advanced DFM software and training our engineers on the latest DFM guidelines, we are confident that we can further improve the quality and efficiency of our PCB manufacturing process."{Company Name}'s dedication to DFM in PCB reflects their ongoing commitment to innovation and excellence in the industry. With their enhanced capabilities, they are well-positioned to meet the evolving needs of their customers and continue to be a leader in the PCB manufacturing sector.

Understanding the Basics of Circuit Boards: A Beginner's Guide

Circuit boards are an essential component of electronic devices, serving as the foundation for the various electrical connections and components that make up a functioning device. They are used in everything from smartphones and laptops to medical devices and automobiles. Understanding the basics of circuit boards is crucial for anyone looking to work in the field of electronics or for those simply interested in learning more about how their devices function.A circuit board, also known as a printed circuit board (PCB), is a flat board that holds and connects electronic components using conductive tracks, pads, and other features. It provides mechanical support for the components while allowing them to be electrically connected. These boards are typically made of non-conductive materials such as fiberglass or plastic, with conductive copper tracks laminated onto the board.The basic structure of a circuit board includes several key elements. The substrate, or base material, provides a solid foundation for the board and its components. The conductive tracks, usually made of copper, form the pathways that transfer electrical signals and power between the various components. The components themselves, such as resistors, capacitors, and integrated circuits (ICs), are mounted onto the board and connected using the conductive tracks. Finally, solder masks and silk screens are applied to the board to protect it and label the different components and connections.Understanding the layout and design of a circuit board is crucial for ensuring proper functionality and reliability. The design process involves determining the placement of components, the routing of electrical connections, and the selection of materials to meet the specific requirements of the device. This process requires a deep understanding of electrical engineering principles, as well as the ability to use specialized computer-aided design (CAD) software.{Company} has been at the forefront of circuit board manufacturing and design for over [X] years. With a strong focus on innovation and quality, the company has established itself as a leader in the industry, providing cutting-edge solutions for a wide range of electronic applications. Their team of experienced engineers and technicians are dedicated to developing high-quality circuit boards that meet the unique needs of their clients.In addition to their expertise in circuit board design, {Company} also offers a range of services including prototyping, assembly, and testing. Their state-of-the-art manufacturing facility is equipped with the latest technology and equipment, allowing them to produce high-quality circuit boards with exceptional precision and efficiency. Whether it's a complex multi-layer board or a simple single-layer design, {Company} is committed to delivering superior products that meet and exceed their customers' expectations.The demand for circuit boards continues to grow as technology advances and new electronic devices are developed. As a result, the need for reliable and high-quality circuit board solutions has never been greater. {Company} is well-positioned to meet this demand, thanks to their extensive expertise and their commitment to innovation and excellence.In conclusion, understanding the basics of circuit boards is essential for anyone working in the field of electronics or anyone interested in learning more about how their devices function. With {Company} leading the way in circuit board design and manufacturing, customers can be confident in the quality and reliability of the products they receive. As technology continues to evolve, the role of circuit boards will only become more important, and {Company} will be there to provide the cutting-edge solutions that the industry demands.

Efficient Smt Pcb Assembly Process: Everything You Need to Know

Smt Pcb Assembly Process Improves Efficiency and Quality for {Company}{Company} is a leading provider of electronic manufacturing services, specializing in Smt Pcb assembly. The company has recently invested in new equipment and technology to enhance its assembly process, aiming to improve efficiency and quality for its clients.The Smt Pcb assembly process is a crucial step in electronic manufacturing, as it involves placing and soldering surface mount components onto printed circuit boards. This process requires precision and accuracy to ensure that the final product meets the highest quality standards.{Company} has always been dedicated to staying at the forefront of technological advancements in electronic manufacturing. With the recent investment in new Smt Pcb assembly equipment, the company has taken its commitment to excellence to the next level.One of the key improvements in the new Smt Pcb assembly process is the use of advanced pick-and-place machines. These machines are equipped with state-of-the-art vision systems and robotics, allowing for faster and more accurate placement of components onto the circuit boards. This upgrade greatly enhances the efficiency of the assembly process, leading to shorter lead times for clients without compromising on quality.Furthermore, {Company} has implemented advanced soldering techniques to ensure the reliability and durability of the assembled Pcb boards. The company uses advanced reflow ovens and selective soldering equipment to achieve optimal solder joints, minimizing the risk of defects and ensuring the long-term performance of the electronic devices.In addition to equipment upgrades, {Company} has also focused on enhancing its quality control procedures in the Smt Pcb assembly process. The company has implemented rigorous inspection and testing protocols to detect and address any potential issues early in the assembly process, preventing defects and ensuring the highest quality of the final products.The investment in the Smt Pcb assembly process aligns with {Company}'s mission to provide its clients with the best possible solutions for their electronic manufacturing needs. The company understands the importance of delivering products that meet the highest quality standards, and the enhanced assembly process is a testament to its dedication to excellence.Clients of {Company} can expect to benefit from the improvements in the Smt Pcb assembly process, as they will experience faster turnarounds, higher quality, and more reliable electronic products. The company is confident that the upgrades will further solidify its position as a trusted partner in the electronic manufacturing industry.The investment in the Smt Pcb assembly process is just one example of {Company}'s continuous efforts to innovate and improve its services. With a team of skilled professionals and a strong focus on technology and quality, the company remains committed to exceeding the expectations of its clients and setting new standards in electronic manufacturing.As the demand for high-quality electronic products continues to grow, {Company} is well-positioned to meet the needs of its clients and adapt to the ever-changing market dynamics. The company's dedication to investing in the latest technology and process improvements ensures that it remains a leader in the electronic manufacturing industry.In conclusion, the recent investment in the Smt Pcb assembly process at {Company} has brought about significant improvements in efficiency and quality. With advanced equipment and technology, the company has strengthened its capabilities and positioned itself as a reliable partner for electronic manufacturing needs. The enhancements in the assembly process are a testament to {Company}'s commitment to excellence and its dedication to exceeding client expectations.

The Importance of Quality PCB Components in Electronic Devices

Pcb Components is a leading provider of high-quality electronic components for a wide range of industries. With a focus on innovation and customer satisfaction, Pcb Components has established itself as a trusted supplier of printed circuit board (PCB) components, including connectors, capacitors, resistors, and much more. The company is committed to providing exceptional products and services to its customers, and has built a strong reputation for reliability and efficiency.Pcb Components works with a diverse range of industries, including automotive, aerospace, telecommunications, and medical devices. The company's broad portfolio of products and solutions allows it to meet the unique needs of each industry, delivering reliable and high-performance components that are essential for the success of its customers' products.One of the key strengths of Pcb Components is its commitment to quality. The company adheres to stringent quality control standards in all aspects of its operations, from sourcing the finest raw materials to the rigorous testing of finished products. This dedication to quality has earned Pcb Components a reputation for excellence, and the company is trusted by some of the biggest names in the industry to deliver components that meet the highest standards.In addition to its focus on quality, Pcb Components prioritizes innovation and continuous improvement. The company invests in research and development to stay at the forefront of technological advancements in the industry, and is constantly developing new and improved components to better serve its customers. By staying ahead of the curve, Pcb Components ensures that its customers have access to the latest and most advanced components available.Furthermore, Pcb Components places a strong emphasis on customer satisfaction. The company is dedicated to building long-term partnerships with its customers, and works closely with them to understand their unique requirements and provide tailored solutions. Pcb Components' team of experts is always on hand to offer technical support and guidance, and the company's responsive customer service ensures that customers receive the assistance they need, when they need it.Based on its long-standing commitment to excellence and customer satisfaction, Pcb Components has become a trusted partner for businesses in need of top-quality electronic components. The company's extensive experience, dedication to quality, and focus on innovation make it a reliable and valuable resource for a wide variety of industries.In recent news, Pcb Components has announced the launch of a new line of cutting-edge connectors designed to meet the demands of next-generation electronics. The new connectors feature state-of-the-art materials and innovative design, offering enhanced performance and reliability for a wide range of applications. With this latest addition to its product portfolio, Pcb Components is poised to further solidify its position as a leader in the electronic components industry."We are excited to introduce our latest line of connectors, which represent the culmination of our ongoing efforts to push the boundaries of innovation and deliver the best possible solutions to our customers," said [company spokesperson]. "These new connectors are the result of extensive research and development, and we believe they will provide significant benefits for our customers in terms of performance, durability, and overall quality."The new connectors are just the latest example of Pcb Components' commitment to innovation and excellence. With a strong track record of delivering top-quality components and a dedication to meeting the evolving needs of its customers, Pcb Components is well positioned to continue its success and remain a trusted partner for businesses seeking reliable electronic components.As Pcb Components continues to expand its product offerings and reach new milestones, the company remains steadfast in its commitment to providing exceptional products and services. With a focus on quality, innovation, and customer satisfaction, Pcb Components has established itself as a leader in the electronic components industry, and is positioned for continued success in the years to come.

Examples of Blue Chip Stocks: Everything You Need to Know

**Title: Exploring Some of the Prominent Blue Chip Stocks in the Market***Introduction*Blue chip stocks are investments in companies with a long-established history of performance, stability, and reliability. These companies are often industry leaders, known for their substantial market capitalization, strong balance sheets, and consistent dividend payouts. In this article, we will delve into some notable blue chip stocks, without specifically mentioning any brand names, to highlight their contribution to the market and their potential as investment options.**Company A - Industry Leader in Technology**Company A operates in the technology sector, which has witnessed exponential growth over the years. With a strong presence in the market, this blue chip company has continuously demonstrated its ability to adapt to evolving consumer demands and market trends. In addition to its innovative products and services, Company A's solid financial performance and impeccable track record make it a reliable investment option for long-term investors. The company's consistent dividend payouts and stable growth have attracted investors seeking steady returns amidst market uncertainties.Driven by a strong management team, Company A continues to invest in research and development, ensuring it remains at the forefront of technological advancements. This commitment positions the company to capitalize on future opportunities and maintain its status as an industry leader.**Company B - Leading the Way in the Healthcare Sector**Company B, a key player in the healthcare sector, has established itself as a prominent blue chip stock in the market. This industry leader operates across various sub-sectors, including pharmaceuticals, biotechnology, and medical device manufacturing.The company's extensive product range and services aim to improve human health and advance medical treatments. Its strong portfolio of patents and a robust pipeline of innovative drugs demonstrate a commitment to research and development.Company B's financial stability and profitability are reflected in its consistent revenue growth and dividend payments. Investors appreciate the company's ability to generate attractive returns while mitigating market risks through diversification across multiple healthcare sub-sectors.Moreover, Company B's strong global footprint and strategic acquisitions provide access to new markets and enhance its competitive position. As the demand for healthcare services and innovation continues to rise, it is likely that Company B will maintain its position as a blue chip stock with ample growth potential.**Company C - Thriving in the Consumer Goods Sector**Company C, a key player in the consumer goods industry, is widely recognized as a blue chip stock due to its long-standing success and market dominance. The company boasts an extensive portfolio of products across multiple categories, enjoying a loyal customer base globally.With a commitment to quality, customer satisfaction, and innovation, Company C stays ahead of its competitors. Focusing on consumer preferences, the company invests in research and development to introduce new and improved products, ensuring continued market relevance.Company C's consistent revenue growth and strong financial performance have attracted investors seeking stability and long-term returns. Additionally, a well-established supply chain and distribution network contribute to the company's ability to penetrate global markets and capitalize on emerging consumer trends.Furthermore, Company C's sustained investment in marketing and advertising campaigns helps maintain its brand equity and drive consumer loyalty. These factors, coupled with the widespread recognition and trust in its products, have positioned the company as a blue chip stock in the consumer goods sector.**Conclusion**While the above companies have been described in a generic manner without specifically naming any brands, these examples give us an understanding of the characteristics that define blue chip stocks. Their consistent performance, solid financials, leading market positions, and commitment to innovation and customer satisfaction make them prominent players in their respective industries.When considering investing in blue chip stocks, thorough analysis and due diligence are crucial. However, their long-term stability, ability to weather market fluctuations, and potential for steady dividend payouts make them attractive choices for conservative investors.Please note that before making any investment decisions, it is important to consult with a financial advisor or conduct independent research to ensure alignment with personal investment goals and risk tolerance.

Quality PCB Assembly House offers efficient services for smooth production

Title: A Leading PCB Assembly House Revolutionizes Electronics ManufacturingIntroduction:In a rapidly evolving technology-driven world, the importance of efficient and reliable Printed Circuit Board (PCB) assembly cannot be overstated. Offering a solution to meet this demand, one prominent PCB assembly house has emerged as an industry leader, spearheading innovation and revolutionizing the electronics manufacturing landscape. With a steadfast commitment to excellence, quality, and customer satisfaction, this company has transformed the way electronics are produced and utilized across various sectors.I. History and Expertise:Established in [year], the PCB assembly house has quickly risen to prominence through its exceptional track record and commitment to technological advancements. With a state-of-the-art manufacturing facility equipped with cutting-edge machinery and a highly skilled workforce, the company has set a benchmark for efficient and high-quality PCB assembly processes.II. Unique Manufacturing Capabilities:The PCB assembly house takes pride in its ability to provide end-to-end solutions that cater to the diverse needs of its clients. From rapid prototyping to high-volume production, the company offers a comprehensive range of services, ensuring that projects are completed with utmost precision and efficiency. By leveraging advanced automation techniques and adhering to stringent quality control measures, the PCB assembly house ensures the production of reliable, durable, and high-performing PCBs.III. Commitment to Quality Assurance:Recognizing the critical role of quality control in the manufacturing process, the company has implemented a rigorous testing regime. Utilizing advanced testing equipment and procedures, each PCB undergoes extensive inspections to ensure conformity to international standards and customer specifications. The assembly house's commitment to quality assurance guarantees that electronic devices produced using their PCBs meet the highest performance standards.IV. Embracing Cutting-edge Technologies:Keeping pace with the rapidly changing technological landscape, the PCB assembly house regularly invests in research and development activities. By collaborating with leading institutions and employing highly skilled engineers, the company stays at the forefront of technological advancements, allowing them to offer innovative solutions to their clients. This forward-thinking approach enables the assembly house to provide PCB designs that optimize performance, functionality, and efficiency.V. Offering Customized Solutions:Recognizing that client requirements vary greatly, the PCB assembly house emphasizes providing tailored solutions. Their team of experienced engineers works closely with clients to develop PCB designs that align with their specific needs, while also considering factors such as size constraints, power consumption, and thermal management. This customer-centric approach ensures that the final product meets and exceeds expectations, effectively addressing unique project requirements.VI. Partnering for Sustainability:In addition to their commitment to technological advancements, the PCB assembly house is equally dedicated to sustainability. Recognizing the industry's impact on the environment, the company employs eco-friendly practices throughout their manufacturing processes. Implementing measures such as recycling programs, waste reduction initiatives, and energy-efficient systems, the assembly house demonstrates its determination to minimize its carbon footprint and contribute to a greener future.Conclusion:As the demand for efficient and high-quality PCB assembly continues to rise, the aforementioned PCB assembly house has emerged as a leading force in the electronics manufacturing industry. Through their dedication to innovation, commitment to quality, and customer-centric approach, they have successfully transformed the manufacturing landscape. By serving as a reliable partner and offering customized solutions, the assembly house has solidified its position as a go-to destination for all PCB assembly needs. With a keen eye on sustainability, the company sets an example for others, combining progressive technologies with environmentally conscious practices to meet the demands of today's market while paving the way for a sustainable future.

Optimizing Flex Circuit Assembly for Improved Performance

Flex Circuit Assembly Company, an industry-leading provider of flexible printed circuit assemblies, has been making waves in the electronic manufacturing services industry with their innovative and cutting-edge solutions. With a strong focus on quality, reliability, and customer satisfaction, the company has built a solid reputation for delivering high-quality flex circuit assemblies that meet the unique needs of their clients.Flex Circuit Assembly Company offers a wide range of services including design, prototyping, manufacturing, and assembly of flexible printed circuit assemblies. Their state-of-the-art facilities and advanced equipment enable them to produce complex and intricate flex circuit assemblies with precision and efficiency. They work closely with their clients to understand their specific requirements and provide customized solutions that meet and exceed their expectations.The company's commitment to excellence is reflected in their rigorous quality control processes and adherence to industry standards. They employ a team of highly skilled and experienced professionals who are dedicated to ensuring that every flex circuit assembly meets the highest standards of performance and reliability. Additionally, Flex Circuit Assembly Company invests in continuous training and development to stay abreast of the latest technologies and advancements in the field, enabling them to deliver innovative and cutting-edge solutions to their clients.One of the key differentiators of Flex Circuit Assembly Company is their ability to offer flexible and scalable manufacturing solutions to accommodate the evolving needs of their clients. Whether it's a small volume prototype or a large-scale production run, the company has the capability to adapt to the project requirements and deliver consistent results. Their flexible manufacturing processes allow for quick turnaround times without compromising on quality, making them a trusted partner for clients across a diverse range of industries.Flex Circuit Assembly Company has a strong track record of successfully delivering flex circuit assemblies for a wide range of applications including medical devices, automotive electronics, consumer electronics, aerospace, and more. Their in-depth industry knowledge and expertise enable them to address the specific challenges and requirements of each sector, providing customized solutions that are tailored to the unique demands of the industry.The company is also committed to sustainability and environmental responsibility, integrating eco-friendly practices into their operations and manufacturing processes. They adhere to strict environmental regulations and work towards minimizing their carbon footprint, ensuring that their operations have minimal impact on the environment.With a customer-centric approach, Flex Circuit Assembly Company places a strong emphasis on building and maintaining long-term relationships with their clients. They prioritize open communication, transparency, and collaboration to ensure that the client's needs are met and their expectations are exceeded. Their dedication to customer satisfaction has earned them a loyal client base and a reputation for being a reliable and trusted partner in the electronic manufacturing services industry.As the demand for flexible printed circuit assemblies continues to grow, Flex Circuit Assembly Company is poised to maintain its position as a leader in the industry. With their unwavering commitment to quality, innovation, and customer satisfaction, the company is well-equipped to address the evolving needs of the market and continue to deliver superior flex circuit assembly solutions to their clients.In conclusion, Flex Circuit Assembly Company stands out as a prominent player in the electronic manufacturing services industry, known for their exceptional quality, reliability, and customer-centric approach. With their comprehensive range of services, advanced capabilities, and commitment to excellence, the company is well-positioned to meet the diverse and evolving needs of clients across various industries.

Different Types of Printed Circuit Boards for Electronics Applications

Printed Circuit Board Types to be Manufactured by {Company}{Company}, a leading electronics manufacturing company, has announced that it will be expanding its product line to include a variety of printed circuit board (PCB) types. As the demand for electronic devices continues to rise, {Company} aims to meet this growing need by offering a wide range of PCB solutions to its customers. The company's commitment to quality and innovation has made it a top choice for businesses in the electronics industry, and the introduction of new PCB types is a testament to its dedication to providing cutting-edge technology.PCBs are essential components in the manufacturing of electronic devices, serving as a platform for connecting and supporting various electronic components. The type of PCB used in a device can greatly impact its performance, making it crucial for manufacturers to choose the right PCB type for their specific application. With the addition of new PCB types to its product line, {Company} aims to provide its customers with the flexibility and customization options they need to create high-quality electronic products.The newly introduced PCB types by {Company} will include single-sided, double-sided, and multi-layer PCBs. Single-sided PCBs are the most basic type of PCB, featuring a single layer of substrate with electronic components mounted on one side. Double-sided PCBs, on the other hand, have a layer of substrate with electronic components mounted on both sides, allowing for more complex circuit designs. Multi-layer PCBs, as the name suggests, consist of multiple layers of substrate with electronic components interconnected through vias, making them suitable for high-performance electronic devices.In addition to these standard PCB types, {Company} will also offer flexible and rigid-flex PCB options. Flexible PCBs are made from flexible plastic materials, allowing them to be bent or twisted without breaking, making them ideal for applications with space constraints or requiring a degree of flexibility. Rigid-flex PCBs, on the other hand, combine both rigid and flexible PCB elements, providing the benefits of both types in a single design. These diverse PCB types will enable {Company} to cater to a wide range of industries and applications, from consumer electronics to automotive and aerospace.With its state-of-the-art manufacturing facilities and advanced technology, {Company} is well-equipped to produce high-quality PCBs that meet the strictest industry standards. The company's commitment to quality control and testing ensures that every PCB it produces is reliable and durable, meeting the performance requirements of its customers' electronic products.In addition to offering a variety of PCB types, {Company} also provides design and engineering support to help customers optimize their PCB designs for performance, cost, and manufacturability. The company's team of experienced engineers and technicians is dedicated to assisting customers at every stage of the product development process, from initial design to final production.As the demand for electronic devices continues to grow, the addition of new PCB types by {Company} underscores its dedication to meeting the evolving needs of its customers. With its comprehensive range of PCB solutions, the company is well-positioned to serve a diverse range of industries and applications, further solidifying its position as a leader in the electronics manufacturing industry.The introduction of new PCB types by {Company} is a testament to its commitment to innovation and customer satisfaction. By offering a wide range of high-quality PCB solutions, the company aims to empower its customers to create cutting-edge electronic products that meet the demands of today's fast-paced market.

Ultimate Guide to Choosing the Best Computer Motherboard in 2022: Everything You Need to Know

A leading computer motherboard manufacturer has recently announced the release of their latest product, the {brand name} motherboard. This new motherboard promises to deliver high performance and seamless connectivity for both gaming and professional use. With its advanced features and cutting-edge technology, the {brand name} motherboard is set to revolutionize the computer hardware industry.{Company name} is a renowned company that has been at the forefront of motherboard manufacturing for many years. They are known for their commitment to innovation and quality, and their products are popular among both casual computer users and hardcore gamers. With a strong focus on research and development, {company name} has consistently pushed the boundaries of what is possible in the world of computer hardware.The {brand name} motherboard is the latest testament to {company name}'s dedication to providing top-of-the-line products to their customers. Equipped with the latest chipset and socket technology, this motherboard is designed to support the latest generation of processors, including those from Intel and AMD. This means that users will have the ability to build a high-performance computer system that can handle even the most demanding tasks and applications.One of the standout features of the {brand name} motherboard is its support for high-speed memory and storage. With support for DDR4 memory and multiple M.2 slots for SSD storage, users can experience lightning-fast data transfer speeds and seamless multitasking capabilities. This makes the {brand name} motherboard an ideal choice for gamers and content creators who require powerful hardware to keep up with their demanding workflows.In addition to its impressive performance capabilities, the {brand name} motherboard also boasts a range of connectivity options. With multiple USB 3.0 and USB-C ports, as well as support for high-speed Wi-Fi and Bluetooth, users can easily connect their peripherals and accessories without any hassle. This level of connectivity is essential for modern computer users who rely on a wide range of devices to get their work done.Furthermore, the {brand name} motherboard features advanced cooling solutions to ensure that the system remains stable even under heavy load. With support for liquid cooling and multiple fan headers, users can keep their system running at optimal temperatures, even during intense gaming sessions or CPU-intensive tasks. This level of thermal management is crucial for maintaining the longevity of the components and ensuring a smooth and reliable computing experience.The {brand name} motherboard also comes with a range of additional features that set it apart from the competition. These include advanced audio technology for immersive sound, RGB lighting options for customization, and comprehensive software utilities for system optimization and monitoring. These features combine to create a motherboard that not only delivers exceptional performance but also provides a user-friendly and enjoyable experience.Overall, the {brand name} motherboard from {company name} represents a significant leap forward in computer hardware technology. Its combination of high performance, advanced features, and reliable build quality make it a compelling choice for anyone looking to build a new computer system. Whether it's for gaming, content creation, or professional use, the {brand name} motherboard is sure to meet the needs of even the most discerning users. With this release, {company name} continues to solidify its position as a leading provider of cutting-edge computer hardware.

How to Assemble PCB: A Step-by-Step Guide

[Company Name] Launches New Line of Assemble PCBs for Enhanced Electronic Manufacturing[City, State] – [Company Name], a leading provider of electronic components and solutions, is proud to announce the launch of its new line of Assemble PCBs. This new line of PCBs is designed to meet the growing demand for high-quality and reliable printed circuit boards in the electronic manufacturing industry.Assemble PCBs are an essential component in the production of electronic devices, ranging from consumer electronics to industrial equipment. They serve as the foundation for connecting electronic components and enabling the functionality of a wide range of devices. With the increasing complexity and miniaturization of electronic products, the demand for advanced PCBs that offer greater reliability and performance has been on the rise.The new line of Assemble PCBs from [Company Name] is designed to address these evolving needs. These PCBs are engineered with the latest technologies and materials to deliver superior performance and durability. They are available in a variety of configurations, including single-sided, double-sided, and multi-layered designs, to accommodate the diverse requirements of electronic manufacturers.One of the key features of the new Assemble PCBs is their advanced manufacturing process. [Company Name] has invested in state-of-the-art production facilities and cutting-edge equipment to ensure the highest level of precision and quality in every PCB. This includes advanced automated assembly lines, precision soldering equipment, and rigorous quality control measures to meet the industry's stringent standards.In addition, the new line of Assemble PCBs is backed by [Company Name]'s commitment to innovation and continuous improvement. The company's team of experienced engineers and technical experts are dedicated to pushing the boundaries of PCB technology, exploring new materials, designs, and manufacturing techniques to stay ahead of industry trends and deliver the most advanced PCB solutions to customers."We are excited to introduce our new line of Assemble PCBs to the market," said [Spokesperson], [Title] at [Company Name]. "These PCBs represent the culmination of our years of experience and expertise in electronic manufacturing. We have carefully engineered them to provide the highest level of performance, reliability, and versatility, to meet the evolving needs of our customers in the electronic industry."The launch of the new line of Assemble PCBs is expected to have a significant impact on the electronic manufacturing industry. With their advanced features and high-quality construction, these PCBs are poised to enhance the performance and reliability of a wide range of electronic products, from consumer electronics to telecommunication devices, medical equipment, and automotive systems.For electronic manufacturers looking to stay ahead in a competitive market, the new line of Assemble PCBs from [Company Name] offers a compelling solution. With their advanced technology, precision manufacturing, and commitment to innovation, these PCBs are set to become an essential component for driving the next generation of electronic devices.About [Company Name]:[Company Name] is a leading provider of electronic components and solutions to the global market. With a focus on quality, innovation, and customer satisfaction, the company offers a wide range of products and services, including PCBs, electronic components, and contract manufacturing solutions. Through its commitment to excellence, [Company Name] aims to empower its customers to succeed in an ever-evolving industry.For more information about [Company Name] and its new line of Assemble PCBs, please visit [website] or contact [contact information].