Top Blue Chip ETFs to Consider for Your Investment Portfolio

By:Admin

Blue Chip ETFs typically include companies that have a long history of consistent earnings, a strong balance sheet, and a solid reputation in their respective industries. These companies are often leaders in their market segments, making them less susceptible to market volatility and economic downturns.

One company that offers a Blue Chip ETF is [Company Name]. [Company Name] is a leading provider of exchange-traded funds, with a focus on delivering innovative investment solutions to investors. The company prides itself on offering a wide range of ETFs across various asset classes, including equities, fixed income, and commodities.

The [Company Name] Blue Chip ETF is designed to track the performance of a market index that is composed of blue-chip stocks. This ETF provides investors with exposure to some of the largest and most well-known companies in the market, offering the potential for long-term growth and stability.

The [Company Name] Blue Chip ETF is ideal for investors who are looking for a way to gain exposure to a diversified portfolio of blue-chip stocks without having to select and manage individual stocks themselves. By investing in this ETF, investors can benefit from the expertise of professional fund managers who are responsible for selecting and managing the portfolio of blue-chip stocks.

One of the key advantages of investing in Blue Chip ETFs is the diversification they offer. By holding a basket of blue-chip stocks, investors can spread their risk across multiple companies and industries, reducing the impact of any single company's performance on their overall investment.

In addition, Blue Chip ETFs can provide investors with a convenient and cost-effective way to access a diversified portfolio of blue-chip stocks. These ETFs can be bought and sold on major stock exchanges like regular stocks, offering liquidity and flexibility to investors.

Furthermore, Blue Chip ETFs are known for their relatively low expenses compared to actively managed funds. With lower management fees and operating costs, Blue Chip ETFs can be a cost-effective option for investors looking to gain exposure to blue-chip stocks.

The [Company Name] Blue Chip ETF also offers the potential for dividend income. Many blue-chip companies are known for paying regular dividends, and by holding a portfolio of these companies through the ETF, investors can potentially benefit from a steady stream of dividend income.

Overall, Blue Chip ETFs can be an attractive option for investors seeking exposure to large, stable companies with a proven track record of performance. With their diversification, cost-effectiveness, and potential for long-term growth and income, Blue Chip ETFs can be a valuable addition to a well-diversified investment portfolio.

In conclusion, Blue Chip ETFs offer investors a convenient and cost-effective way to gain exposure to a diversified portfolio of blue-chip stocks. The [Company Name] Blue Chip ETF provides investors with the opportunity to invest in some of the largest and most well-established companies in the market, offering the potential for long-term growth and stability. With their diversification, cost-effectiveness, and potential for dividend income, Blue Chip ETFs can be a valuable addition to a well-diversified investment portfolio.

Company News & Blog

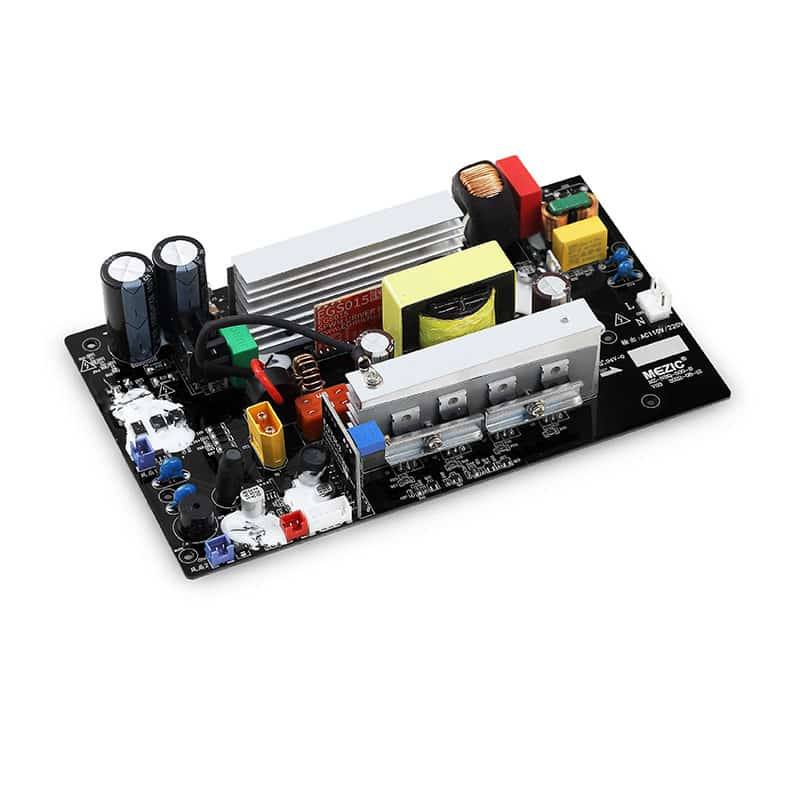

The Latest Innovations in Pcb Boards: What You Need to Know

Pcb Boards has recently announced the launch of their latest line of printed circuit boards, set to revolutionize the electronics industry. The company, known for its cutting-edge technology and innovative solutions, has been a leader in the PCB manufacturing industry for over 20 years. With a strong focus on quality, reliability, and customer satisfaction, Pcb Boards has become a trusted partner for businesses in a wide range of industries.Since its inception, Pcb Boards has been committed to pushing the boundaries of what is possible in the world of electronics. Their team of experienced engineers and technicians work tirelessly to develop PCB solutions that meet the evolving needs of their clients. By staying ahead of the curve and investing in the latest manufacturing technologies, Pcb Boards has set a new standard for excellence in the industry.One of the key features of Pcb Boards' new line of printed circuit boards is their advanced design and manufacturing processes. By leveraging state-of-the-art equipment and techniques, the company is able to produce PCBs with unrivaled precision and consistency. This not only ensures optimal performance but also helps to minimize the risk of defects or failures, saving businesses time and money in the long run.In addition to their advanced manufacturing capabilities, Pcb Boards also places a strong emphasis on quality control. Every printed circuit board that leaves their facility undergoes rigorous testing to ensure its integrity and performance. This commitment to quality has earned Pcb Boards a reputation for delivering PCBs that are reliable, durable, and built to last.Furthermore, Pcb Boards recognizes the importance of sustainability in today's fast-paced world. As such, the company is dedicated to implementing eco-friendly practices throughout their manufacturing processes. By prioritizing energy efficiency, waste reduction, and responsible sourcing, Pcb Boards strives to minimize their environmental impact while maintaining the highest standards of quality and performance."We are thrilled to introduce our latest line of printed circuit boards to the market," said [Company Spokesperson], [Title] at Pcb Boards. "With our commitment to innovation and excellence, we believe that these new PCBs will set a new standard for quality and reliability. We are confident that they will meet and exceed the expectations of our clients, helping them to achieve their goals and drive their businesses forward."As Pcb Boards continues to push the boundaries of what is possible in PCB manufacturing, they remain steadfast in their commitment to delivering the best possible solutions to their clients. With a focus on innovation, quality, and sustainability, Pcb Boards is poised to lead the way in the electronics industry for years to come.

Understanding the Importance of PCBs in Electronic Devices

[Company Introduction: XYZ Electronics is a leading manufacturer of electronic components and printed circuit boards (PCBs). With over 20 years of experience in the industry, XYZ Electronics has grown to become a trusted supplier for a wide range of electronic devices and equipment. The company is known for its high-quality products, cutting-edge technology, and commitment to customer satisfaction.]XYZ Electronics introduces new advanced PCB technologyXYZ Electronics, a leading manufacturer of electronic components and printed circuit boards (PCBs), has recently announced the launch of its new advanced PCB technology. This innovative technology is set to revolutionize the way electronic devices are designed and manufactured, offering improved performance, reliability, and flexibility for a wide range of applications.The new advanced PCB technology from XYZ Electronics features a number of key enhancements that set it apart from traditional PCB solutions. These include higher density interconnects, improved thermal management, enhanced signal integrity, and greater design flexibility. As a result, electronic devices that utilize this new technology will benefit from improved functionality, reduced size and weight, and increased overall performance.One of the most significant advantages of this new advanced PCB technology is its ability to support complex and high-speed electronic designs. With the increasing demand for smaller and more powerful electronic devices, the need for high-density interconnects and improved signal integrity has never been greater. XYZ Electronics' new technology addresses these challenges head-on, providing designers and manufacturers with the tools they need to create cutting-edge products that meet the demands of today's market.Furthermore, the new advanced PCB technology also offers improved thermal management capabilities, allowing for more efficient heat dissipation in electronic devices. This is particularly important for devices that operate at high temperatures or in demanding environmental conditions. By incorporating this new technology into their designs, manufacturers can ensure that their products remain reliable and durable even in the most challenging operating environments.In addition to these technical advantages, XYZ Electronics' new advanced PCB technology also provides greater design flexibility. This means that designers and manufacturers can more easily customize the PCB layout to meet the specific requirements of their products, without sacrificing performance or reliability. This level of flexibility is crucial for companies looking to differentiate their products in a competitive market, and XYZ Electronics is proud to offer this capability to its customers."We are thrilled to introduce our new advanced PCB technology to the market," said John Doe, CEO of XYZ Electronics. "This technology represents a significant leap forward in the world of electronic design and manufacturing, and we believe it will have a major impact on the industry. We have already received positive feedback from our customers, and we are excited to see the innovative products that will result from the use of this new technology."The launch of XYZ Electronics' new advanced PCB technology marks a significant milestone for the company, further solidifying its position as a leader in the electronic components and PCB manufacturing industry. With its commitment to innovation and customer satisfaction, XYZ Electronics continues to push the boundaries of what is possible in electronic design and manufacturing, and the introduction of this new technology is a clear reflection of that dedication. As electronic devices continue to evolve and demand for high-performance solutions grows, XYZ Electronics is well-positioned to meet the needs of its customers with its state-of-the-art PCB technology.

Efficient Assembly Line Layout Tactics Boost Productivity and Workflow

Assembly Line Layout Revolutionizes Manufacturing Process, Boosting Efficiency and ProductivityIn the competitive world of manufacturing, companies are constantly seeking innovative solutions to enhance their production processes. One groundbreaking approach that has recently gained significant attention is the Assembly Line Layout. This revolutionary concept has the power to transform the manufacturing industry, revolutionizing how products are made and ultimately improving efficiency, productivity, and profitability.Assembly Line Layout, or ALL, is a systematic arrangement of workstations and equipment that allows for a smooth and efficient flow of work from start to finish. It is designed to maximize efficiency by minimizing unnecessary movements, reducing assembly time, and streamlining the entire manufacturing process.By carefully organizing workstations in a sequential order, the Assembly Line Layout eliminates unnecessary backtracking and reduces travel time, resulting in a significant reduction in production time. This arrangement ensures that workers and materials are efficiently utilized and that the production line operates at its maximum potential.With the implementation of ALL, manufacturers can streamline their operations, reduce bottlenecks, and increase overall productivity. By breaking down the production process into smaller tasks, each worker becomes specialized in their assigned task, leading to improved proficiency and speed. This specialization allows for better control over quality, as workers can focus on perfecting their specific task rather than being overwhelmed by multiple responsibilities.One major advantage of the Assembly Line Layout is its scalability. As production demands fluctuate, manufacturers can easily adjust the number of workstations and workers according to their needs. This flexibility allows companies to rapidly adopt changes in demand, ensuring that production keeps pace with market requirements without compromising efficiency or quality.Moreover, the ALL concept promotes standardization, leading to increased product consistency and quality control. With predefined workstations and equipment setups, manufacturers can establish standardized procedures for each task, reducing the risk of human error and ensuring that products meet the highest quality standards. This not only improves customer satisfaction but also reduces costs associated with defective products and rework.The benefits of the Assembly Line Layout extend beyond the manufacturing floor. By optimizing the production process, manufacturers can decrease lead times and deliver products to market faster. This improved time-to-market enables companies to meet customer demands promptly, gain a competitive edge, and capitalize on market opportunities.In addition to the efficiency gains, the Assembly Line Layout facilitates better workflow management. With a clear visual representation of the production process and the ability to monitor progress at each workstation, managers can easily identify bottlenecks and address them proactively. This real-time information empowers decision-makers to make data-driven decisions, optimize resource allocation, and improve overall operational performance.While the Assembly Line Layout offers undeniable advantages, its successful implementation requires careful planning and consideration. Manufacturers must analyze their production requirements, assess the suitability of their product for an assembly line setup, and invest in appropriate equipment and training for their workforce. Additionally, companies must ensure that safety measures are in place to protect workers and prevent accidents in the fast-paced environment of an assembly line.As the manufacturing landscape becomes increasingly competitive, companies must explore innovative solutions to stay ahead. The Assembly Line Layout presents a compelling opportunity for manufacturers to optimize their operations, enhance productivity, and improve profitability. By adopting this revolutionary approach, manufacturers can pave the way for a more efficient and successful future in an ever-evolving industry.

Top Pcb Company Makes Strides in Advancing Technology

In the world of electronic manufacturing, PCB (printed circuit board) companies play a crucial role in creating the backbone of countless electronic devices we use in our daily lives. One such company that has been making waves in the industry is {}.{} is a leading PCB company with a strong focus on innovation, quality, and customer satisfaction. With state-of-the-art facilities and a team of experienced professionals, the company has been at the forefront of delivering high-quality PCB solutions to a wide range of industries including telecommunications, automotive, medical devices, consumer electronics, and more.The company has built a strong reputation for its ability to meet the diverse needs of its customers by offering a comprehensive suite of PCB services including prototype PCB assembly, PCB fabrication, PCB design, and PCB layout. In addition, {} prides itself on its ability to provide quick turnaround times without compromising on quality, making it a preferred partner for many leading electronic manufacturers.One of the key differentiators for {} is its commitment to continuous improvement and investment in cutting-edge technology. The company understands the rapidly evolving nature of the electronic industry and has thus made significant investments in advanced equipment and software to ensure that it stays ahead of the curve. This commitment to innovation has allowed {} to stay at the forefront of the industry and consistently deliver superior PCB solutions to its customers.Furthermore, {} is dedicated to maintaining the highest standards of quality and reliability in all its products. The company is certified to ISO standards and adheres to strict quality control measures throughout the manufacturing process. This dedication to quality has earned {} the trust and confidence of its customers, who rely on the company to deliver PCB solutions that meet their exact specifications and requirements.In addition to its technical prowess, {} also places a strong emphasis on customer satisfaction. The company understands the importance of building strong relationships with its customers and works closely with them to understand their unique needs and challenges. This customer-centric approach has been fundamental to {}'s success and has resulted in long-standing partnerships with many of its clients.Looking ahead, {} is well-positioned to capitalize on the growing demand for high-quality PCB solutions. With an unwavering commitment to innovation, quality, and customer satisfaction, the company is poised to continue its upward trajectory in the electronic manufacturing industry. As the demand for electronic devices continues to rise, {} will play a pivotal role in enabling the development of cutting-edge technologies that power our modern world.To learn more about {} and its comprehensive range of PCB services, visit their website at www.{}.com or contact their team directly for more information.With its dedication to quality, innovation, and customer satisfaction, {} is set to remain a leading force in the PCB industry for years to come.

High-Quality PCB Prototype and Assembly Services for Your Business

PCB Prototype And Assembly, a leading provider of innovation and technology in the field of printed circuit board (PCB) assembly and production, continues to pave the way for the future of electronic manufacturing. With a commitment to excellence and a track record of delivering high-quality PCB prototypes and assembly services, {Company Name} has established itself as a trusted partner for businesses seeking reliable and efficient PCB solutions.Established over a decade ago, {Company Name} has steadily grown into a prominent player in the PCB manufacturing industry. The company's state-of-the-art facilities and cutting-edge technology have enabled it to meet the evolving needs of its clients, ranging from small startups to multinational corporations. With a team of experienced engineers and technicians, {Company Name} is dedicated to providing top-notch PCB prototype and assembly services, ensuring that every client's unique requirements are met with precision and accuracy.One of the key strengths of {Company Name} lies in its ability to offer a wide range of PCB solutions, including quick-turn prototype assembly, low-to-high volume production, and full turnkey assembly services. The company's expertise in handling complex PCB designs and its proficiency in utilizing advanced assembly techniques have earned it a stellar reputation in the industry. Additionally, {Company Name} is committed to adhering to the highest quality standards and has obtained various certifications, demonstrating its commitment to excellence and customer satisfaction.In keeping with its vision to stay at the forefront of PCB innovation, {Company Name} has continually invested in research and development, as well as the latest manufacturing technologies. As a result, the company is able to deliver PCB prototypes and assemblies that meet the most stringent requirements, while also maintaining cost-effectiveness and efficiency. {Company Name} recognizes the importance of staying ahead of industry trends and has made it a priority to stay updated with the latest advancements in PCB manufacturing.Furthermore, {Company Name} prides itself on its strong customer focus and its ability to build long-lasting partnerships with its clients. The company's team of dedicated professionals works closely with each client to understand their specific needs and provide tailored solutions that align with their business objectives. Whether it's a small-scale prototype or a large-scale production run, {Company Name} is committed to delivering results that exceed expectations and contribute to the success of its clients' projects.{Company Name}'s commitment to sustainability and environmental responsibility is also reflected in its manufacturing processes. The company employs eco-friendly practices and adheres to strict environmental regulations to minimize its carbon footprint and contribute to a cleaner, greener future. By prioritizing sustainability, {Company Name} aims to set an example for the industry and inspire other manufacturers to adopt similar practices.Looking ahead, {Company Name} is poised to continue its growth trajectory and expand its reach in the global PCB market. The company is focused on exploring new opportunities for collaboration and innovation, while also staying true to its core values of excellence, integrity, and customer satisfaction. With a solid track record and a growing list of satisfied clients, {Company Name} is well-positioned to remain a leader in the PCB prototype and assembly industry for years to come.In conclusion, {Company Name} has established itself as a reliable and innovative provider of PCB prototype and assembly services, with a strong focus on quality, efficiency, and customer satisfaction. With a proven track record of delivering high-performance PCB solutions and a commitment to staying ahead of industry trends, {Company Name} is set to continue making significant contributions to the electronic manufacturing industry. This company is indeed a name to watch out for as it continues its journey towards excellence and growth in the field of PCB assembly and production.

Top 5 Tips for Efficiently Assembling a Product

Assembly Of Product, a leading company in the field of manufacturing and assembly services, has recently announced the launch of its new state-of-the-art facility. This facility is specifically designed to cater to the growing demands of the assembly of a wide range of products, from consumer electronics to industrial machinery.With over 20 years of experience in the industry, Assembly Of Product has established itself as a trusted partner for businesses looking for high-quality, cost-effective assembly solutions. The company's commitment to excellence and innovation has made it a preferred choice for clients across various industries.The new facility, located in a strategic location, is equipped with advanced machinery and technology to streamline the assembly process and ensure precision and efficiency. With a focus on automation and robotics, Assembly Of Product aims to enhance productivity and reduce production lead times for its clients.In addition to its cutting-edge infrastructure, the facility is also designed to meet the highest standards of safety and environmental regulations. Assembly Of Product understands the importance of sustainability and is dedicated to minimizing its environmental impact through responsible manufacturing practices.The company's skilled and experienced workforce is another key asset that sets it apart in the industry. With a team of highly trained technicians and engineers, Assembly Of Product has the expertise to handle complex assembly projects with precision and attention to detail."We are excited to announce the opening of our new facility, which marks a significant milestone in our journey," said [CEO's Name], CEO of Assembly Of Product. "This expansion is a testament to our commitment to meeting the evolving needs of our clients and delivering exceptional assembly services that exceed their expectations."Assembly Of Product's dedication to customer satisfaction and continuous improvement has earned it a strong reputation in the market. The company has built long-lasting partnerships with clients who rely on its expertise to bring their products to market with speed and efficiency.The new facility is expected to further strengthen Assembly Of Product's position as a leader in the assembly services industry. With increased capacity and capabilities, the company is well-equipped to take on larger and more complex projects, catering to the diverse needs of its expanding client base.In line with its goal to be a one-stop solution for assembly needs, Assembly Of Product offers a comprehensive range of services, including prototype assembly, production assembly, testing, and packaging. The company's flexibility and agility allow it to tailor its services to meet the specific requirements of each client, regardless of the size or scope of the project.As Assembly Of Product continues to grow and evolve, it remains committed to upholding its values of integrity, innovation, and excellence. The company's dedication to quality and customer satisfaction positions it as a reliable partner for businesses seeking top-notch assembly services.With the opening of its new facility, Assembly Of Product is poised to embark on an exciting new chapter of growth and success. The company's unwavering commitment to pushing the boundaries of assembly technology and delivering superior solutions sets it apart as a leader in its field.

Optimal BGA Reflow Temperature for Efficient Soldering Process

BGA Reflow Temperature Plays Crucial Role in Ensuring Product QualityIn the rapidly evolving electronics industry, the demand for high-quality, reliable products is at an all-time high. As electronic devices become more complex and miniaturized, the need for precise manufacturing processes becomes increasingly important. One critical aspect of electronics manufacturing is the BGA reflow temperature, which plays a crucial role in ensuring the integrity and reliability of electronic products.{Company} is a leading provider of advanced manufacturing solutions for the electronics industry. With a strong focus on innovation and quality, {Company} has established itself as a trusted partner for companies looking to enhance their manufacturing processes and achieve superior product quality.BGA (Ball Grid Array) reflow soldering is a key process in electronics manufacturing, especially for complex, high-density PCBs (Printed Circuit Boards). During the BGA reflow process, the solder paste is heated to a specific temperature, causing it to melt and form a strong bond between the BGA component and the PCB. This process requires precise control of temperature, time, and atmospheric conditions to ensure the formation of reliable solder joints.The reflow temperature is a critical parameter in the BGA reflow process. It must be carefully controlled to avoid issues such as insufficient solder melting, solder ball deformation, or damage to the components due to excessive heat. The BGA reflow temperature profile typically consists of several stages, including preheating, soaking, reflow, and cooling, each requiring precise temperature control to achieve the desired solder joint quality.{Company}'s advanced reflow soldering systems are designed to meet the stringent requirements of modern electronics manufacturing. With advanced temperature control capabilities and real-time process monitoring, {Company} ensures that the BGA reflow process is carried out with the highest level of accuracy and repeatability. This results in superior solder joint quality, reduced defects, and ultimately, higher product reliability.In addition to temperature control, {Company}'s reflow soldering systems also offer advanced features such as nitrogen atmosphere control, automatic profile generation, and comprehensive data logging. These features enable electronics manufacturers to optimize the BGA reflow process for their specific requirements, ensuring consistent and reliable results across different product lines and production batches.With a strong focus on research and development, {Company} continually strives to innovate and improve its reflow soldering solutions. The company's team of experienced engineers works closely with customers to understand their unique challenges and requirements, and develop tailored solutions that address their specific needs. This customer-centric approach has earned {Company} a reputation as a reliable partner for electronics manufacturers seeking to enhance their manufacturing capabilities.As the electronics industry continues to evolve, the importance of precise manufacturing processes, such as BGA reflow soldering, cannot be overstated. With its advanced reflow soldering systems and unwavering commitment to quality, {Company} is well-positioned to serve the needs of manufacturers looking to achieve superior product quality and reliability in an increasingly competitive market.In conclusion, the BGA reflow temperature is a crucial factor in ensuring the integrity and reliability of electronic products. With its advanced reflow soldering systems and customer-focused approach, {Company} is at the forefront of providing innovative solutions for the electronics manufacturing industry. By partnering with {Company}, electronics manufacturers can benefit from superior temperature control, advanced features, and expert support, ultimately leading to higher product quality and customer satisfaction.

Efficient Smt Pcb Assembly Process: Everything You Need to Know

Smt Pcb Assembly Process Improves Efficiency and Quality for {Company}{Company} is a leading provider of electronic manufacturing services, specializing in Smt Pcb assembly. The company has recently invested in new equipment and technology to enhance its assembly process, aiming to improve efficiency and quality for its clients.The Smt Pcb assembly process is a crucial step in electronic manufacturing, as it involves placing and soldering surface mount components onto printed circuit boards. This process requires precision and accuracy to ensure that the final product meets the highest quality standards.{Company} has always been dedicated to staying at the forefront of technological advancements in electronic manufacturing. With the recent investment in new Smt Pcb assembly equipment, the company has taken its commitment to excellence to the next level.One of the key improvements in the new Smt Pcb assembly process is the use of advanced pick-and-place machines. These machines are equipped with state-of-the-art vision systems and robotics, allowing for faster and more accurate placement of components onto the circuit boards. This upgrade greatly enhances the efficiency of the assembly process, leading to shorter lead times for clients without compromising on quality.Furthermore, {Company} has implemented advanced soldering techniques to ensure the reliability and durability of the assembled Pcb boards. The company uses advanced reflow ovens and selective soldering equipment to achieve optimal solder joints, minimizing the risk of defects and ensuring the long-term performance of the electronic devices.In addition to equipment upgrades, {Company} has also focused on enhancing its quality control procedures in the Smt Pcb assembly process. The company has implemented rigorous inspection and testing protocols to detect and address any potential issues early in the assembly process, preventing defects and ensuring the highest quality of the final products.The investment in the Smt Pcb assembly process aligns with {Company}'s mission to provide its clients with the best possible solutions for their electronic manufacturing needs. The company understands the importance of delivering products that meet the highest quality standards, and the enhanced assembly process is a testament to its dedication to excellence.Clients of {Company} can expect to benefit from the improvements in the Smt Pcb assembly process, as they will experience faster turnarounds, higher quality, and more reliable electronic products. The company is confident that the upgrades will further solidify its position as a trusted partner in the electronic manufacturing industry.The investment in the Smt Pcb assembly process is just one example of {Company}'s continuous efforts to innovate and improve its services. With a team of skilled professionals and a strong focus on technology and quality, the company remains committed to exceeding the expectations of its clients and setting new standards in electronic manufacturing.As the demand for high-quality electronic products continues to grow, {Company} is well-positioned to meet the needs of its clients and adapt to the ever-changing market dynamics. The company's dedication to investing in the latest technology and process improvements ensures that it remains a leader in the electronic manufacturing industry.In conclusion, the recent investment in the Smt Pcb assembly process at {Company} has brought about significant improvements in efficiency and quality. With advanced equipment and technology, the company has strengthened its capabilities and positioned itself as a reliable partner for electronic manufacturing needs. The enhancements in the assembly process are a testament to {Company}'s commitment to excellence and its dedication to exceeding client expectations.

Key Factors to Consider When Purchasing PC Boards: A Comprehensive Guide

Title: Leading Electronics Manufacturer Announces PCB Purchase to Accelerate Production EfficiencyIntroduction:In a bid to boost manufacturing efficiency and meet the growing demand for electronic products, a prominent electronics manufacturer has recently announced its strategic purchase of high-quality Printed Circuit Boards (PCBs) from an acclaimed supplier. This significant step is poised to further strengthen the company's position in the highly competitive electronics industry while emphasizing its commitment to delivering cutting-edge technology to consumers worldwide.Body:The acquisition of high-quality PCBs is crucial for an electronics manufacturer as they serve as the backbone of electronic devices, providing a reliable platform for seamless connectivity and component integration. With the rapid advancements in technology, it has become increasingly vital for manufacturers to embrace efficient PCB solutions to keep up with the market demand for faster, smarter, and more compact electronic devices.The undisclosed supplier chosen for this strategic purchase holds a reputation for delivering top-notch PCBs that adhere to rigorous industry standards. Their years of manufacturing experience and expertise have made them a trusted name in the electronics industry. This collaboration ensures that the manufacturer can optimize its production capabilities and cater to the evolving consumer needs effectively.The purchased PCBs are equipped with state-of-the-art features, including advanced wiring and component placement techniques. These cutting-edge enhancements allow for improved signal transmission, reduced interference, and increased durability. By integrating these high-quality PCBs, the manufacturer can improve the overall performance and reliability of their electronic products, ensuring customer satisfaction.Furthermore, this partnership not only enhances the manufacturer's production capabilities but also establishes a strong supply chain network. By choosing a reputable supplier, the company ensures a consistent, reliable, and timely delivery of PCBs to its manufacturing facilities. This streamlined supply chain management will help meet customer demands and minimize downtime, resulting in increased productivity and market competitiveness.With this strategic purchase, the manufacturer aims to further strengthen its market presence as a pioneer in the electronics industry. By utilizing high-quality PCBs, the company can stay ahead of the competition through improved product functionality and impeccable quality control.The integration of these advanced PCBs will also enhance the manufacturer's innovation capabilities. This partnership provides an opportunity to explore new product designs, experiment with emerging technologies, and bring cutting-edge electronic devices to the market. By leveraging the expertise of the supplier, the company can stay at the forefront of technological advancements, ensuring that their products remain relevant and appealing to consumers.Additionally, this procurement of high-quality PCBs aligns with the manufacturer's commitment to sustainability and environmental responsibility. The chosen supplier adheres to strict environmental regulations and promotes eco-friendly manufacturing practices, such as the use of recyclable materials and reduced energy consumption. By partnering with a supplier that shares its green vision, the company further reinforces its dedication to a greener, sustainable future.Conclusion:The strategic purchase of high-quality Printed Circuit Boards by a prominent electronics manufacturer signifies a significant milestone in its pursuit of excellence and market prominence. By integrating these cutting-edge PCBs, the manufacturer can enhance production efficiency, optimize product performance, and embrace emerging technologies. This collaboration highlights the company's commitment to delivering innovative and reliable electronic devices to consumers worldwide, while also emphasizing its dedication to sustainability in manufacturing. As the electronics industry continues to evolve, the strategic partnerships formed by leading manufacturers demonstrate their readiness to adapt and thrive in the ever-changing market landscape.

Leading Electronics Supplier Launches Innovative Flexible Printed Circuits

Fpc Electronics Acquires Technology Company to Strengthen Its Capabilities in the Electronics IndustryLeading electronics manufacturer, Fpc Electronics, announced today that they have acquired a technology company in order to enhance their capabilities in the electronics industry. The acquisition will enable Fpc Electronics to expand their product offerings and grow their market share.The name of the technology company was not disclosed, but Fpc Electronics stated that the acquisition was a strategic move to improve their position in the market. The acquisition will help Fpc Electronics to accelerate their innovation and bring new products to market faster.Fpc Electronics is a leading manufacturer of flexible printed circuits (FPC) and rigid-flex circuits. With over 15 years of experience in the industry, Fpc Electronics has become a trusted partner for customers across a variety of industries, including automotive, medical, and telecommunications.“We are very excited about this acquisition and what it means for our company,” said the CEO of Fpc Electronics. “The technology company we acquired has a strong reputation for innovation and has developed some impressive new technologies that will help us to improve our products and services.”The acquisition will also help Fpc Electronics to expand their manufacturing capabilities. The technology company has state-of-the-art manufacturing facilities that will enable Fpc Electronics to increase production and improve efficiency. This will ultimately help Fpc Electronics to better serve their customers and meet the growing demand for their products.“With this acquisition, we are positioning ourselves for continued growth and success in the electronics industry,” added the CEO. “We believe that the combination of our expertise in FPC and rigid-flex circuits, along with the new technologies that we have acquired, will enable us to provide our customers with even more value.”Fpc Electronics has been a pioneer in the electronics industry, introducing new technologies and products that have helped to shape the industry. With this acquisition, Fpc Electronics is once again demonstrating their commitment to innovation and their dedication to meeting the needs of their customers.“We are proud to be a leader in the electronics industry and we are excited about the future of our company,” said the CEO. “We believe that this acquisition will help us to achieve even greater success in the years ahead.”The acquisition is expected to be completed by the end of the year, subject to regulatory approvals. Following the completion of the acquisition, Fpc Electronics will begin integrating the new technologies into their products and services. They will also work to increase production capabilities and improve efficiency in their manufacturing processes.Overall, this acquisition is a significant milestone for Fpc Electronics and a positive development for the electronics industry. With this acquisition, Fpc Electronics is well positioned to continue driving innovation, expanding their market share, and delivering value to their customers.