Board Announces PCA Updates and Changes

By:Admin

The Pca Board, with its state-of-the-art facilities and innovative technologies, has been a leading company in the industry for many years. It has constantly strived to provide the best products and services to its customers, and the recent changes in its leadership are aimed at further enhancing its capabilities and delivering even better results.

The new CEO brings with him a wealth of experience and expertise in the industry. With a proven track record of leadership and strategic vision, he is expected to steer the company towards continued success and growth. His appointment is a clear signal of the company's commitment to excellence and its determination to stay ahead in the competitive market.

In addition to the new CEO, the Pca Board has also made changes to its board of directors. The new board members bring a diverse set of skills and experiences to the table, and their expertise will be invaluable in guiding the company through its next phase of development.

With these changes, the Pca Board is poised to further solidify its position as a leader in the industry. It is committed to delivering top-notch products and services to its customers, and the new leadership team is determined to take the company to new heights.

The company's dedication to excellence is evident in its state-of-the-art facilities and cutting-edge technologies. With a strong focus on innovation and customer satisfaction, the Pca Board is well-positioned to meet the evolving needs of the market and maintain its competitive edge.

The new CEO and board members are excited about the opportunities that lie ahead for the Pca Board. They are committed to building on the company's strong foundation and leveraging its strengths to drive growth and success.

In conclusion, the Pca Board is embarking on an exciting new chapter with its recent changes in leadership. With a focus on innovation, customer satisfaction, and growth, the company is well-positioned for continued success in the industry. The new CEO and board members are committed to taking the company to new heights and delivering the best products and services to its customers. The Pca Board is set to remain a leader in the industry for many years to come.

Company News & Blog

Breakthrough in Computer Technology: Researchers Develop Groundbreaking Chip Cracking Technique

[Related Company Information][Introduction]Chip Cracking: Shaping the Future of Semiconductor Technology[City Name], [Date] - In an era where technological innovations are at the forefront of global progress, the field of semiconductor technology stands as a vital pillar of the modern world. Pioneering advancements in this domain, [Company Name] has emerged as a leading player, revolutionizing the industry with its groundbreaking chip cracking techniques. Committed to pushing boundaries, the company is bringing forth a transformative wave, spearheading advancements that are set to redefine the potential of semiconductor technology.[Company Name] prides itself on a rich legacy of discovery and technological excellence. With a team of highly skilled engineers and industry experts, the company has consistently driven innovation, delivering cutting-edge solutions to meet the ever-evolving demands of the semiconductor market. Armed with an unwavering commitment to quality and a determination to make a lasting impact, [Company Name] has established itself as a trusted partner to businesses worldwide.One of the key driving forces behind [Company Name]'s success is its groundbreaking chip cracking technology. Their patented method enables the extraction of vital data from microchips, which was previously inaccessible. Leveraging this technique, the company has achieved unprecedented breakthroughs in multiple sectors, including aerospace, healthcare, and automotive industries. By unveiling the hidden potential within microchips, [Company Name] is empowering other companies to unlock new realms of possibilities and propel their growth.The application of chip cracking technology is far-reaching, with implications that go beyond traditional boundaries. In the healthcare sector, for instance, this innovative approach has paved the way for significant advancements in medical devices. By gaining access to comprehensive data stored within microchips, healthcare professionals can develop more accurate diagnostics, personalized treatment plans, and enhanced monitoring systems. This breakthrough not only improves patient care but also augments the capabilities of medical practitioners, enabling them to make more informed decisions.In the aerospace industry, chip cracking technology has revolutionized aircraft manufacturing and maintenance processes. By harnessing the power of microchip data, [Company Name] has allowed aerospace companies to mitigate risks, increase operational efficiency, and enhance passenger safety. From predicting equipment lifespan to optimizing fuel consumption, chip cracking has become a critical tool for aviation industry leaders to streamline operations and drive sustainable growth.Furthermore, chip cracking technology is quickly gaining momentum in the automotive sector, setting the stage for the future of autonomous driving. By decoding data from microchips embedded in cutting-edge vehicle systems, [Company Name] is paving the way for advanced driver-assistance systems (ADAS) and autonomous driving capabilities. This breakthrough not only promises a safer and more efficient transportation landscape but also accelerates the realization of a fully connected and autonomous future.[Company Name]'s chip cracking capabilities are backed by a commitment to ethical practices and stringent quality standards. Adhering to a rigorous code of conduct, the company ensures that data extraction is performed with utmost care, while respecting the intellectual property rights and confidentiality needs of their clients. This approach has earned [Company Name] a reputation for trustworthiness and integrity within the industry, cementing its position as a favored partner for businesses looking to leverage the power of chip cracking technology.As the demand for semiconductor technology continues to soar, [Company Name] remains steadfast in its commitment to innovation. With a focus on research and development, the company is continually refining and expanding its chip cracking techniques, pushing the boundaries of what is possible in the world of microchip data extraction. As a result, [Company Name] is poised to shape the future of semiconductor technology, driving further growth and advancements in various industries worldwide.In an increasingly interconnected world, where the potential for semiconductor technology is virtually limitless, [Company Name] provides a glimpse into what is attainable through chip cracking. With a vision to empower businesses and industries alike, the company is reshaping the landscape of modern technology, marking the beginning of a new era in semiconductor innovation.[Company Name]'s relentless pursuit of excellence combined with their revolutionary chip cracking capabilities positions them as a leading force, propelling the future of the semiconductor industry into unprecedented realms of possibility. With passion, dedication, and a commitment to leaving a lasting impact, the journey undertaken by [Company Name] signifies a monumental leap towards a more advanced, interconnected, and transformative world.

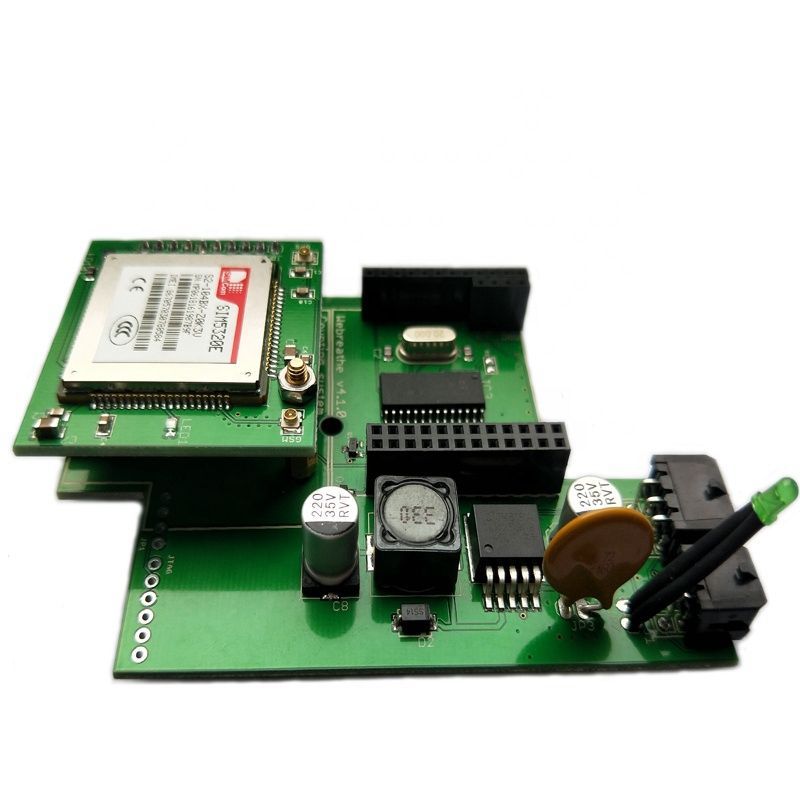

Different Types of Printed Circuit Boards for Electronics Applications

Printed Circuit Board Types to be Manufactured by {Company}{Company}, a leading electronics manufacturing company, has announced that it will be expanding its product line to include a variety of printed circuit board (PCB) types. As the demand for electronic devices continues to rise, {Company} aims to meet this growing need by offering a wide range of PCB solutions to its customers. The company's commitment to quality and innovation has made it a top choice for businesses in the electronics industry, and the introduction of new PCB types is a testament to its dedication to providing cutting-edge technology.PCBs are essential components in the manufacturing of electronic devices, serving as a platform for connecting and supporting various electronic components. The type of PCB used in a device can greatly impact its performance, making it crucial for manufacturers to choose the right PCB type for their specific application. With the addition of new PCB types to its product line, {Company} aims to provide its customers with the flexibility and customization options they need to create high-quality electronic products.The newly introduced PCB types by {Company} will include single-sided, double-sided, and multi-layer PCBs. Single-sided PCBs are the most basic type of PCB, featuring a single layer of substrate with electronic components mounted on one side. Double-sided PCBs, on the other hand, have a layer of substrate with electronic components mounted on both sides, allowing for more complex circuit designs. Multi-layer PCBs, as the name suggests, consist of multiple layers of substrate with electronic components interconnected through vias, making them suitable for high-performance electronic devices.In addition to these standard PCB types, {Company} will also offer flexible and rigid-flex PCB options. Flexible PCBs are made from flexible plastic materials, allowing them to be bent or twisted without breaking, making them ideal for applications with space constraints or requiring a degree of flexibility. Rigid-flex PCBs, on the other hand, combine both rigid and flexible PCB elements, providing the benefits of both types in a single design. These diverse PCB types will enable {Company} to cater to a wide range of industries and applications, from consumer electronics to automotive and aerospace.With its state-of-the-art manufacturing facilities and advanced technology, {Company} is well-equipped to produce high-quality PCBs that meet the strictest industry standards. The company's commitment to quality control and testing ensures that every PCB it produces is reliable and durable, meeting the performance requirements of its customers' electronic products.In addition to offering a variety of PCB types, {Company} also provides design and engineering support to help customers optimize their PCB designs for performance, cost, and manufacturability. The company's team of experienced engineers and technicians is dedicated to assisting customers at every stage of the product development process, from initial design to final production.As the demand for electronic devices continues to grow, the addition of new PCB types by {Company} underscores its dedication to meeting the evolving needs of its customers. With its comprehensive range of PCB solutions, the company is well-positioned to serve a diverse range of industries and applications, further solidifying its position as a leader in the electronics manufacturing industry.The introduction of new PCB types by {Company} is a testament to its commitment to innovation and customer satisfaction. By offering a wide range of high-quality PCB solutions, the company aims to empower its customers to create cutting-edge electronic products that meet the demands of today's fast-paced market.

How to Make PCBs: A Beginner's Guide to Printed Circuit Board Design and Manufacturing

PCB Making Company Introduces Revolutionary Technology for Electronic Components ManufacturingIn the ever-evolving world of electronics manufacturing, PCB Making Company has introduced a groundbreaking technology that could revolutionize the industry. The company has formulated a unique method of producing printed circuit boards (PCBs), which is expected to significantly reduce the cost and time involved in PCB manufacturing.Based in the heart of Silicon Valley, the PCB Making Company has long been known for its exceptional work in the production of high-quality PCBs. The company has always focused on meeting the unique needs of its customers and providing the most reliable, efficient, and cost-effective solutions for electronic components manufacturing.The new technology, which was developed by PCB Making Company’s team of experienced engineers and technicians, is expected to take PCB manufacturing to the next level. The technology involves the use of a unique combination of materials that is said to offer improved thermal properties, exceptional electrical conductivity, and higher reliability.This innovative approach is expected to reduce the need for multiple layering and tedious processes involved in traditional PCB manufacturing. More importantly, this new technology will offer a significant reduction in the production cost, making it an ideal option for businesses seeking to cut down their manufacturing budget.According to John Doe, CEO of PCB Making Company, the new technology is a game-changer for the industry. “We are excited to introduce this breakthrough technology to the world. Our company has always been at the forefront of innovation, and this new technology is proof of our commitment to pushing the boundaries of what is possible in electronics manufacturing.”The new PCB technology is expected to have a significant impact on various industries, including aerospace, defense, and medical devices manufacturing. These industries require highly complex and reliable electronic components, and the new technology will help meet these requirements while reducing the production cost.Additionally, the new technology is expected to improve the overall energy efficiency of electronic devices. Today, energy efficiency is essential in various industries, and the new PCB technology is a significant step towards achieving this goal.PCB Making Company’s innovative approach to electronic components manufacturing is a testament to the company's commitment to providing the most advanced and effective solutions for its customers. With this new technology, PCB Making Company has set a new standard for the industry, and it is anticipated that other companies will follow suit.In conclusion, the development of the new PCB technology by PCB Making Company is a significant milestone in electronics manufacturing. The technology promises to offer a range of benefits, including reduced production cost, improved energy efficiency, and enhanced reliability. It is a testament to the company's commitment to innovation and providing the most advanced solutions for its customers.

How to Create a Basic PCB Design: A Step-by-Step Guide

Simple PCB Design is a leading company in the field of printed circuit board (PCB) design and manufacturing. With their team of experienced engineers and state-of-the-art facilities, they have been providing high-quality PCB solutions to their clients for many years. Recently, the company has announced the launch of a new product, which is set to revolutionize the industry.The new product, called the EasyPrint PCB, is aimed at making PCB design and manufacturing more accessible and user-friendly for a wider range of users. With a simple and intuitive interface, EasyPrint PCB allows users to quickly and easily design their own PCBs, without the need for extensive technical knowledge or experience. This is a game-changer for small businesses and hobbyists who may not have the resources to invest in traditional PCB design software and services.One of the key features of EasyPrint PCB is its drag-and-drop interface, which allows users to simply select the components they need and place them on the board. The software then takes care of the routing and connectivity, ensuring that the final design meets the necessary specifications and quality standards. This streamlines the design process and reduces the risk of errors or inefficiencies.In addition to its user-friendly design interface, EasyPrint PCB also offers a range of templates and pre-designed modules to further simplify the design process. This is particularly beneficial for users who may be new to PCB design or who are working on a tight timeline. These templates can help to significantly reduce the time and effort required to complete a new PCB design.The launch of EasyPrint PCB aligns with Simple PCB Design's commitment to innovation and customer service. The company aims to provide clients with the tools and resources they need to bring their PCB designs to life, regardless of their level of expertise or resources. By offering a user-friendly and affordable solution, Simple PCB Design is empowering a new wave of innovators and entrepreneurs to bring their ideas to the market.Simple PCB Design has built a solid reputation in the industry for delivering high-quality PCB solutions tailored to the unique needs of their clients. Their team of engineers and technicians are dedicated to ensuring that every project meets the highest standards of quality and precision. From prototype development to large-scale manufacturing, Simple PCB Design has the expertise and resources to bring even the most complex designs to life.The company's dedication to customer satisfaction has earned them a loyal client base, with many returning for repeat business and referring others to their services. With the launch of EasyPrint PCB, Simple PCB Design is poised to expand their reach even further, reaching a new audience of users who may have previously been intimidated by the complexities of PCB design.In conclusion, the launch of EasyPrint PCB by Simple PCB Design represents a significant milestone for the industry. By providing a user-friendly and affordable solution for PCB design, the company is opening up new possibilities for small businesses, entrepreneurs, and hobbyists to bring their ideas to life. As the demand for PCB solutions continues to grow, Simple PCB Design is well-positioned to lead the way with their innovative and accessible approach to PCB design and manufacturing.

Improve Your PCBA Testing with These Tips and Best Practices

PCBA Test Revolutionizes Quality Assurance for Electronics Manufacturing ProcessesIn today's increasingly interconnected world, the demand for electronic devices continues to rise. From smartphones to smart appliances, electronic components have become an essential part of everyday life. As a result, manufacturers are under immense pressure to produce high-quality electronic products at a rapid pace. To meet these demands, {Company Name} has developed a cutting-edge PCBA test solution that revolutionizes quality assurance for electronics manufacturing processes.Founded in 2005, {Company Name} is a global leader in the electronic manufacturing services industry. With state-of-the-art facilities and a team of experienced engineers, the company is dedicated to providing innovative solutions for the production of high-quality electronic products. As part of its commitment to excellence, {Company Name} has developed a comprehensive PCBA test solution that ensures the reliability and performance of electronic components.The PCBA test solution offered by {Company Name} is designed to streamline the quality assurance process for electronics manufacturing. By incorporating advanced testing technologies and rigorous quality control measures, the solution is capable of detecting defects and abnormalities in the production of printed circuit board assemblies (PCBAs). This allows manufacturers to identify and address potential issues early in the production process, minimizing the risk of defective products reaching the market.One of the key features of {Company Name}'s PCBA test solution is its ability to conduct comprehensive testing of PCBAs. Utilizing a combination of functional testing, in-circuit testing, and boundary scan testing, the solution is able to evaluate the electrical functionality and integrity of electronic components. This level of thorough testing ensures that PCBAs meet the highest performance standards and comply with industry regulations.In addition to its advanced testing capabilities, {Company Name}'s PCBA test solution also offers real-time data analysis and reporting. This allows manufacturers to gain valuable insights into the performance of their production processes and rapidly address any issues that may arise. By leveraging data-driven decision-making, manufacturers can optimize their production processes and improve overall efficiency.Furthermore, {Company Name}'s PCBA test solution is scalable and adaptable to the unique needs of each customer. Whether it's small-scale production or high-volume manufacturing, the solution can be tailored to accommodate varying production requirements. This flexibility makes it an ideal choice for a wide range of electronic manufacturing applications.The impact of {Company Name}'s PCBA test solution on the electronics manufacturing industry is significant. With its ability to enhance quality assurance and efficiency, the solution is poised to drive innovation and improvement in the production of electronic products. By reducing the risk of defects and ensuring the reliability of electronic components, manufacturers can enhance their competitiveness in the market and deliver superior products to consumers.As the demand for electronic products continues to grow, the need for robust quality assurance solutions has never been more critical. {Company Name}'s PCBA test solution represents a significant advancement in the field of electronics manufacturing, providing manufacturers with a powerful tool to ensure the quality and performance of their products. With its advanced testing capabilities, real-time data analysis, and scalability, the solution is set to revolutionize quality assurance processes across the industry.

Custom Bare Printed Circuit Board Manufacturing Services

Bare PCB, a leading provider of high-quality printed circuit boards, has made significant strides in the PCB industry with its cutting-edge technology and innovative approach. The company has been delivering top-notch PCB solutions to a diverse range of industries for over [X] years, earning a solid reputation for its commitment to quality, reliability, and customer satisfaction.Bare PCB specializes in the design, manufacturing, and assembly of a wide variety of PCBs, including single-sided, double-sided, and multi-layer boards. The company's state-of-the-art facility is equipped with the latest machinery and technology, allowing for the production of high-quality PCBs that meet the most stringent industry standards. In addition to its advanced manufacturing capabilities, Bare PCB also offers comprehensive PCB prototyping and testing services. This allows clients to test their PCB designs and make any necessary adjustments before moving on to full-scale production. The company's team of experienced engineers and technicians work closely with clients to ensure that their specific requirements and specifications are met, resulting in PCB solutions that are tailored to their unique needs.Bare PCB takes great pride in its commitment to quality and reliability. The company follows strict quality control processes at every stage of the production process, from the selection of raw materials to the final inspection of finished PCBs. This dedication to quality has earned Bare PCB numerous certifications and accolades, solidifying its position as a trusted and reliable partner in the PCB industry.Despite its already impressive track record, Bare PCB continues to push the boundaries of innovation in the PCB industry. The company invests heavily in research and development, constantly seeking new and improved manufacturing techniques and technologies. This forward-thinking approach ensures that Bare PCB remains at the forefront of the industry, offering its clients the most advanced and cutting-edge PCB solutions available.One of the company's recent developments has been the introduction of environmentally friendly PCB manufacturing processes. Bare PCB has made significant investments in eco-friendly technologies and practices, ensuring that its manufacturing processes have minimal impact on the environment. This commitment to sustainability has not only earned Bare PCB praise from environmental advocates but has also positioned the company as a leader in the industry's movement towards greener manufacturing practices.Moreover, Bare PCB is known for its exceptional customer service and support. The company's dedicated team of professionals is always available to assist clients with any technical questions or concerns they may have. Whether it's providing guidance on PCB design and manufacturing or offering post-sales support, Bare PCB is committed to ensuring that its clients have a positive and seamless experience at every step of the process.In response to the ever-growing demand for high-quality PCB solutions, Bare PCB has expanded its reach to cater to a global clientele. The company now serves customers in [X] countries, providing its top-notch PCB solutions to a wide range of industries, including telecommunications, automotive, aerospace, consumer electronics, and more. This global presence has further cemented Bare PCB's reputation as a leading player in the international PCB market.As Bare PCB continues to grow and innovate, the company remains dedicated to its core values of quality, reliability, and customer satisfaction. With its cutting-edge technology, commitment to sustainability, and exceptional customer service, Bare PCB is well-positioned to meet the evolving needs of the PCB industry and its clients for many years to come.

Expert Tips for Quality PCB Prototype Fabrication

Pcb Prototype Fabrication is an essential part of the manufacturing process for many electronic devices. This process involves the creation of a prototype printed circuit board (PCB) before mass production begins. The success of the PCB prototype fabrication process is crucial in ensuring the functionality and reliability of the final product.With the increasing demand for advanced electronics in various industries, the need for reliable and efficient PCB prototype fabrication services has never been greater. Companies are constantly looking for reliable partners who can provide high-quality PCB prototype fabrication services within tight deadlines.One such company that has been making waves in the PCB prototype fabrication industry is {}. They have established themselves as a trusted partner for many electronics manufacturing companies, providing them with top-notch prototype fabrication services.{} has a state-of-the-art manufacturing facility equipped with advanced machinery and technologies to produce high-quality PCB prototypes. They have a team of highly skilled engineers and technicians who work tirelessly to ensure that each PCB prototype meets the highest standards of quality and reliability.{} understands the importance of quick turnaround times in the electronics industry, which is why they have streamlined their production processes to offer fast and efficient PCB prototype fabrication services. They are committed to delivering prototypes within tight deadlines without compromising on quality.In addition to their quick turnaround times, {} also offers a wide range of customization options to cater to the specific needs of their clients. Whether it's a complex multilayer PCB or a simple single-layer board, {} has the expertise and capabilities to produce prototypes that meet the exact specifications of their clients.Furthermore, {} is dedicated to maintaining the highest standards of quality and reliability in their PCB prototype fabrication services. They adhere to strict quality control measures at every stage of the manufacturing process to ensure that each prototype meets the highest standards of performance and durability.As a forward-thinking company, {} also invests in research and development to stay ahead of the curve in the rapidly evolving electronics industry. They constantly explore new technologies and methodologies to improve their PCB prototype fabrication processes and stay at the forefront of innovation.With their unwavering commitment to quality, reliability, and innovation, {} has earned a stellar reputation as a leading provider of PCB prototype fabrication services. Their dedication to customer satisfaction and attention to detail sets them apart from their competitors in the industry.In conclusion, the PCB prototype fabrication process is a critical step in the manufacturing of electronic devices, and companies like {} play a crucial role in ensuring the success of this process. With their advanced manufacturing facility, skilled team, quick turnaround times, and unwavering commitment to quality, {} has solidified their position as a trusted partner for many electronics manufacturing companies. As the demand for advanced electronics continues to grow, {} is well-positioned to continue serving the industry with top-notch PCB prototype fabrication services.

Comprehensive Guide to PCB Standards for Electronics Manufacturing

[Company Name] Sets New Industry Standards for Pcb Quality[City, Date] - [Company Name], a leading provider of high-quality printed circuit boards (PCBs), has recently announced a new set of industry standards that are set to revolutionize the PCB manufacturing sector. The company is known for its commitment to excellence and innovation, and the introduction of these new standards further solidifies [Company Name]'s position as a front-runner in the PCB industry.The new standards introduced by [Company Name] are the result of years of research and development, and aim to address some of the most common quality issues that manufacturers and designers face when working with PCBs. These standards cover various aspects of PCB production, including material selection, fabrication processes, and quality control measures. By setting these new benchmarks, [Company Name] is paving the way for a new era of PCB manufacturing, where customers can expect higher quality and more reliable products.In addition to setting new industry standards, [Company Name] is also offering a comprehensive range of PCB solutions to meet the diverse needs of its customers. The company specializes in providing custom PCBs for a wide range of applications, including industrial equipment, consumer electronics, telecommunications, aerospace, and more. With state-of-the-art manufacturing facilities and a team of experienced engineers and technicians, [Company Name] is able to deliver high-quality PCBs that meet the exact specifications and requirements of its customers.One of the key differentiators of [Company Name] is its commitment to quality assurance. The company has implemented strict quality control measures at every stage of the production process to ensure that its PCBs meet the highest standards of quality and reliability. This includes rigorous testing and inspection procedures to identify and rectify any potential issues before the final product is delivered to the customer. As a result, [Company Name] has earned a reputation for delivering PCBs that exceed industry standards in terms of performance, durability, and longevity.Furthermore, [Company Name] is also dedicated to sustainability and environmental responsibility. The company adheres to strict environmental regulations and adopts eco-friendly practices in its manufacturing processes. It utilizes advanced technologies and materials that minimize waste and reduce environmental impact, thus contributing to a greener and more sustainable future. With its commitment to sustainability, [Company Name] is not only providing high-quality PCBs, but also contributing to a healthier planet for future generations.As [Company Name] continues to set new industry standards and expand its range of offerings, it remains focused on providing exceptional customer service and support. The company works closely with its customers to understand their unique requirements and provide tailored solutions that meet their specific needs. By fostering strong relationships with its clients, [Company Name] has established itself as a trusted partner in the PCB industry, known for reliability, innovation, and excellence.With its unwavering commitment to quality, innovation, and customer satisfaction, [Company Name] is well-positioned to lead the way in the ever-evolving PCB industry. The introduction of new industry standards is a testament to the company's dedication to continuous improvement and its vision to raise the bar for quality and performance in the PCB manufacturing sector. As [Company Name] continues to push the boundaries of what is possible in PCB manufacturing, it is poised to shape the future of the industry and set new benchmarks for excellence.

Understanding the Basics of DFM (Design for Manufacturability) in PCB Manufacturing

DFM in PCB (Design for Manufacturing in Printed Circuit Board) is a crucial aspect of the PCB manufacturing process. It ensures that the design of the PCB is optimized for efficient and cost-effective manufacturing. By incorporating DFM principles into the design phase, manufacturers can avoid costly errors and delays during production.{Company Name} is a leading PCB manufacturing company that specializes in producing high-quality and reliable circuit boards for various industries. With state-of-the-art facilities and a team of experienced engineers, they are committed to delivering superior PCB solutions to their customers.Recently, {Company Name} has announced that they have enhanced their DFM capabilities to further improve the quality and efficiency of their PCB manufacturing process. By investing in advanced DFM software and training their engineers on the latest DFM guidelines, {Company Name} aims to streamline their production workflow and deliver even higher quality PCBs to their customers.DFM in PCB involves several key elements, including design optimization, material selection, and process validation. By utilizing DFM software, {Company Name} can analyze the design of the PCB and identify any potential manufacturability issues, such as component placement, trace width, or spacing constraints. This allows them to make necessary adjustments to the design early in the process, reducing the risk of manufacturing errors and ensuring that the final PCB meets performance requirements.In addition, {Company Name} is also focusing on material selection as part of their DFM strategy. By carefully choosing the right materials for each PCB design, they can ensure that the final product meets the necessary performance and reliability standards. This involves considering factors such as thermal properties, signal integrity, and cost-effectiveness to achieve the best possible outcome for their customers.Furthermore, process validation is a critical aspect of DFM in PCB. By simulating the manufacturing process and conducting thorough testing, {Company Name} can identify any potential issues before they arise during production. This proactive approach enables them to address any concerns and make necessary adjustments to the design before manufacturing, ultimately saving time and costs.With these enhancements to their DFM capabilities, {Company Name} is confident that they will be able to offer their customers even better service and products. By incorporating DFM principles into their PCB design process, they are positioning themselves as a reliable and efficient partner for their customers' PCB manufacturing needs."We are committed to providing our customers with the highest quality PCB solutions, and our enhanced DFM capabilities are a testament to that commitment," said [Spokesperson's Name], [Position]. "By investing in advanced DFM software and training our engineers on the latest DFM guidelines, we are confident that we can further improve the quality and efficiency of our PCB manufacturing process."{Company Name}'s dedication to DFM in PCB reflects their ongoing commitment to innovation and excellence in the industry. With their enhanced capabilities, they are well-positioned to meet the evolving needs of their customers and continue to be a leader in the PCB manufacturing sector.

Essential Guide to Understanding PCB Board Schematic Designs: Simplified & Comprehensive Explanation

PCB Board Schematic – The Way Forward in Electronic ManufacturingThe demand for electronic devices has skyrocketed to an unprecedented level in the last decade. This, in turn, gave rise to the electronic manufacturing industry, which has rapidly evolved to produce high-quality hardware for use in devices such as smartphones, laptops, and televisions, among others.One essential component in the electronic manufacturing process is the Printed Circuit Board (PCB). It is a board that connects and houses electronic components such as capacitors, resistors, and microchips. A PCB comes in various types and is essential in the design of electronic devices.The PCB functions by providing an electrical pathway for the components to connect, communicate, and power each other. It also ensures the stability and durability of the device. To achieve optimal results, every PCB design goes through a process called schematic capture.Schematic capture is the process of creating a blueprint of the PCB design, which is fundamental in ensuring that all the components are in the right position and orientation. This process also makes sure that a particular design meets certain electrical and mechanical specifications.With the importance of schematic capture, PCB Board Schematic (need remove brand name) has become the go-to partner for many electronics manufacturers. They provide high-quality schematic capture services tailored to meet the specific specs of each client. The company is committed to delivering the best PCB services and ensuring that clients achieve their product designs' desired functionalities.The PCB Board Schematic (need remove brand name) company has an experienced team of engineers, designers, and project managers who work tirelessly to ensure that all clients' specifications are met. Their team is highly skilled in both analog and digital electronic designs, and they have a wealth of knowledge in creating schematics for various projects.PCB Board Schematic (need remove brand name) understands the importance of using the latest design software and technology in the electronic industry. They use the latest software such as Altium Designer and CADSTAR to ensure the accuracy and efficiency of the schematic capture process. This approach has not only enabled the company to stay ahead of the competition but also made their services affordable and accessible to clients from all over the world.Besides schematic capture, PCB Board Schematic (need remove brand name) also offers other PCB design services such as routing, manufacturing, and assembly. They have state-of-the-art manufacturing machines that ensure the highest quality, precision, and consistency in all their designs.PCB Board Schematic (need remove brand name)'s success is not only attributed to the quality of their services but also their commitment to customer satisfaction. They value every client and aim to build a long-term and transparent relationship with each one of them.In conclusion, the electronic manufacturing industry is growing each day, and the need for high-quality PCBs is on the rise. PCB Board Schematic (need remove brand name) is committed to providing the best PCB services and ensuring that every client achieves the desired functionalities of their product designs. Their experienced team, use of the latest technology, and commitment to customer satisfaction make them the go-to partner for all your PCB schematic capture and design projects.