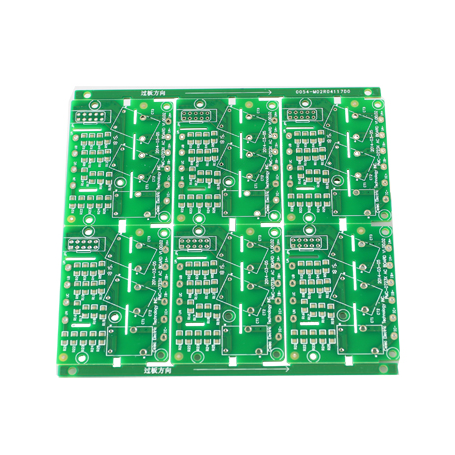

High-Quality Rapid Prototype PCB Board Manufacturing Services Available

By:Admin

With the increasing pace of technology development, companies are under pressure to bring new products to market quickly. This is especially true for smaller companies and startups that are looking to stay ahead of the competition. Fast Turn Prototype PCB Board understands the needs of these companies and has developed a product that can help them achieve their goals.

The Fast Turn Prototype PCB Board is designed to be produced in a short amount of time without sacrificing quality. This is achieved through a combination of advanced manufacturing processes and a focus on efficiency. The company utilizes state-of-the-art equipment and production techniques to ensure that each prototype PCB board meets the highest standards of quality and reliability.

In addition to fast turnaround times, the Fast Turn Prototype PCB Board also offers a high degree of customization. This allows companies to quickly iterate on their designs and make changes as needed, without having to wait for long lead times. The ability to rapidly prototype and test new designs is crucial for companies looking to innovate and stay ahead of the curve.

One of the key advantages of the Fast Turn Prototype PCB Board is its ability to reduce time-to-market for new products. By streamlining the prototyping process, companies can bring their ideas from concept to reality in a fraction of the time it would take with traditional PCB manufacturing methods. This allows companies to get their products into the hands of customers faster, gaining a competitive edge in the market.

The Fast Turn Prototype PCB Board is also suitable for a wide range of applications, including consumer electronics, automotive, medical devices, and more. The company offers a variety of materials and finishes to meet the specific needs of each application, ensuring that the end product meets the required performance and reliability standards.

Fast Turn Prototype PCB Board is committed to providing the highest level of customer service and support. The company's team of experts is available to help customers at every stage of the prototyping process, from design assistance to troubleshooting and technical support. This level of support ensures that customers can move quickly through the prototyping process and get their products to market as soon as possible.

"We are excited to introduce the Fast Turn Prototype PCB Board to the market," said [Company Spokesperson]. "We understand the challenges that companies face in bringing new products to market quickly, and our new offering is designed to address these challenges head-on. With our fast turnaround times and high-quality prototypes, we are confident that the Fast Turn Prototype PCB Board will become an essential tool for companies looking to innovate and succeed in today's fast-paced electronic manufacturing industry."

For companies looking to accelerate their product development cycle and get their ideas to market quickly, the Fast Turn Prototype PCB Board is the ideal solution. With its combination of fast turnaround times, high quality, and customization options, this new offering from Fast Turn Prototype PCB Board is poised to revolutionize the prototyping process and help companies stay ahead of the competition.

Company News & Blog

Ultimate Guide to Light PCBs: Everything You Need to Know

Light PCB, a leading manufacturer in the field of printed circuit boards (PCBs), has recently announced the launch of their latest product line aimed at revolutionizing the lighting industry. With their cutting-edge technology and expertise in PCB manufacturing, the company is set to bring innovative solutions to the market and provide high-quality, reliable products to their customers.Light PCB has been a prominent player in the PCB industry for over a decade, with a strong focus on research and development to consistently improve their products and services. The company is committed to delivering excellence in both quality and performance, making them a trusted partner for businesses operating in various industries.The newly introduced product line from Light PCB is designed to address the growing demand for advanced lighting solutions in residential, commercial, and industrial settings. The company's innovative PCBs are crucial components in the manufacturing of LED lighting systems, enabling higher energy efficiency, longer lifespan, and superior performance. By integrating advanced materials and manufacturing processes, Light PCB is able to produce PCBs that meet the highest standards in the industry.In addition to their technical capabilities, Light PCB also takes pride in their commitment to sustainability and environmental responsibility. The company's manufacturing processes adhere to strict environmental regulations and they continuously strive to minimize their ecological footprint. By choosing Light PCB as their supplier, businesses can contribute to a more sustainable future while benefiting from high-quality, environmentally-friendly products.One of the key advantages of Light PCB's products is their versatility and adaptability. The company's PCBs can be customized to meet specific requirements, ensuring that they seamlessly integrate with different lighting systems and applications. Whether it's for architectural lighting, automotive lighting, horticultural lighting, or any other specialized use, Light PCB has the expertise and resources to deliver tailored solutions that exceed expectations.Furthermore, Light PCB places a strong emphasis on customer satisfaction and support. Their team of skilled professionals is dedicated to providing responsive and personalized service to every client, from initial consultation to after-sales support. By fostering strong relationships with their customers, Light PCB aims to become a trusted partner that businesses can rely on for their PCB needs.As the global demand for energy-efficient lighting solutions continues to rise, Light PCB is well-positioned to capitalize on this trend and make a significant impact in the industry. Their forward-thinking approach and investment in advanced technologies have allowed them to stay ahead of the curve, delivering products that are at the forefront of innovation.In conclusion, Light PCB's latest product line represents a significant milestone for the company and the lighting industry as a whole. With their combination of technical expertise, commitment to sustainability, and dedication to customer satisfaction, Light PCB is poised to set new standards for quality and performance in the PCB market. Businesses looking to incorporate advanced lighting solutions into their operations can confidently turn to Light PCB for reliable, high-quality PCBs that meet their specific needs.

Customized Printed Circuit Board Manufacturer – All You Need to Know About Prototypes

Proto Pcb, a leading manufacturer of printed circuit boards, has recently announced a major breakthrough in the field of electronic component manufacturing. The company, known for its innovative and cutting-edge technologies, has developed a revolutionary new process that promises to transform the way printed circuit boards are produced. This development represents a significant advancement in the industry and has the potential to greatly impact the electronic component manufacturing supply chain.Proto Pcb has been a key player in the electronic component manufacturing industry for over two decades. The company has consistently demonstrated its commitment to innovation and has a track record of developing state-of-the-art technologies that push the boundaries of what is possible in the field.The new process developed by Proto Pcb is a game-changer in the printed circuit board manufacturing industry. This innovative method promises to revolutionize the way printed circuit boards are produced, significantly reducing production costs and increasing efficiency. By streamlining the manufacturing process, Proto Pcb expects to deliver higher quality products at a faster pace, ultimately benefiting consumers and the industry as a whole.This breakthrough is the result of years of research and development by Proto Pcb's team of highly skilled engineers and scientists. The company has invested significant resources into developing this new process, recognizing the potential impact it could have on the industry. The successful development of this revolutionary manufacturing process is a testament to Proto Pcb's dedication to pushing the boundaries of what is possible in electronic component manufacturing.The implications of this breakthrough are far-reaching. By introducing this new process, Proto Pcb is poised to disrupt the traditional methods of printed circuit board manufacturing. The company's innovative approach has the potential to set a new standard for electronic component manufacturing, leading to a more efficient and cost-effective supply chain.In addition to the potential impact on the industry, this breakthrough is also expected to benefit consumers. With a more efficient and cost-effective manufacturing process, Proto Pcb will be able to deliver higher quality printed circuit boards at a more competitive price. This could lead to cost savings for manufacturers and ultimately result in more affordable electronic devices for consumers.Proto Pcb's commitment to innovation and continuous improvement has been a driving force behind this breakthrough. The company has a long history of pioneering new technologies and this latest development is a testament to its ongoing efforts to stay at the forefront of the electronic component manufacturing industry.As a leader in the field, Proto Pcb has a reputation for delivering high-quality products and providing exceptional customer service. The company's dedication to excellence has earned it a strong reputation and a loyal customer base. With this latest breakthrough, Proto Pcb is once again demonstrating its commitment to delivering innovative solutions that meet the evolving needs of the industry.The impact of this breakthrough on the electronic component manufacturing industry is expected to be profound. Proto Pcb's new process has the potential to transform the way printed circuit boards are produced, leading to a more efficient and cost-effective supply chain. This development is a significant step forward for the industry and further solidifies Proto Pcb's position as a leader in electronic component manufacturing.In conclusion, Proto Pcb's groundbreaking new manufacturing process represents a major advancement in the field of electronic component manufacturing. This innovative approach has the potential to transform the industry, leading to more efficient and cost-effective production of printed circuit boards. With this latest breakthrough, Proto Pcb continues to demonstrate its commitment to innovation and excellence, setting a new standard for the electronic component manufacturing industry.

What Are the Differences Between SMT and SMD Components?

SMT and SMD Technology Revolutionizing Electronic ManufacturingIn the fast-paced world of electronic manufacturing, Surface Mount Technology (SMT) and Surface Mount Device (SMD) have revolutionized the way electronic components are mounted onto circuit boards. These advancements have allowed for increased efficiency, improved performance, and reduced manufacturing costs, making them essential components of modern electronic production processes.SMT is a method of electronic component assembly that utilizes automated machines to place components onto the surface of a printed circuit board (PCB). This technology has largely replaced the older through-hole technology, which required components to be inserted into holes drilled through the PCB and then soldered in place. SMT has significantly reduced the size of electronic devices while increasing their functionality and reliability.SMD refers to the actual components that are mounted onto the PCB using SMT. These components are specially designed to be compact and lightweight, making them ideal for use in modern electronic devices. SMD components include resistors, capacitors, diodes, and integrated circuits, among others. These components play a critical role in the functionality of electronic devices, and their small size allows for densely populated PCBs without sacrificing performance.The company {}, founded in 1995, has been at the forefront of the SMT and SMD revolution, supplying high-quality components and manufacturing equipment to electronic manufacturers worldwide. The company offers a comprehensive range of SMD components, including resistors, capacitors, diodes, and integrated circuits, as well as a variety of SMT manufacturing equipment such as pick-and-place machines, soldering equipment, and inspection systems.With a focus on innovation and quality, {} has become a trusted partner for electronic manufacturers looking to maximize efficiency and performance while reducing production costs. The company's dedication to providing cutting-edge technology and superior customer service has earned them a reputation as a leading provider in the electronic manufacturing industry.In addition to providing SMD components and manufacturing equipment, {} also offers comprehensive support and training programs to help manufacturers integrate SMT and SMD technology into their production processes. This ensures that customers are able to fully utilize the benefits of this advanced technology, resulting in improved product quality and increased profitability.As electronic devices continue to become smaller, more powerful, and more complex, the demand for SMT and SMD technology is expected to grow. Manufacturers are constantly striving to increase the performance and functionality of their products, while also reducing production costs. SMT and SMD technology have proven to be essential in meeting these demands, and companies like {} are at the forefront of driving this innovation forward.With a commitment to excellence and a focus on continuous improvement, {} is poised to continue leading the way in the SMT and SMD industry, providing manufacturers with the tools and expertise they need to succeed in an increasingly competitive market.In conclusion, SMT and SMD technology have significantly transformed the electronic manufacturing industry, leading to smaller, more powerful, and more reliable electronic devices. As the demand for advanced electronic products continues to grow, the importance of SMT and SMD technology will only continue to increase. With companies like {} driving innovation and providing comprehensive solutions, the future of electronic manufacturing looks brighter than ever.

How to Make PCBs: A Beginner's Guide to Printed Circuit Board Design and Manufacturing

PCB Making Company Introduces Revolutionary Technology for Electronic Components ManufacturingIn the ever-evolving world of electronics manufacturing, PCB Making Company has introduced a groundbreaking technology that could revolutionize the industry. The company has formulated a unique method of producing printed circuit boards (PCBs), which is expected to significantly reduce the cost and time involved in PCB manufacturing.Based in the heart of Silicon Valley, the PCB Making Company has long been known for its exceptional work in the production of high-quality PCBs. The company has always focused on meeting the unique needs of its customers and providing the most reliable, efficient, and cost-effective solutions for electronic components manufacturing.The new technology, which was developed by PCB Making Company’s team of experienced engineers and technicians, is expected to take PCB manufacturing to the next level. The technology involves the use of a unique combination of materials that is said to offer improved thermal properties, exceptional electrical conductivity, and higher reliability.This innovative approach is expected to reduce the need for multiple layering and tedious processes involved in traditional PCB manufacturing. More importantly, this new technology will offer a significant reduction in the production cost, making it an ideal option for businesses seeking to cut down their manufacturing budget.According to John Doe, CEO of PCB Making Company, the new technology is a game-changer for the industry. “We are excited to introduce this breakthrough technology to the world. Our company has always been at the forefront of innovation, and this new technology is proof of our commitment to pushing the boundaries of what is possible in electronics manufacturing.”The new PCB technology is expected to have a significant impact on various industries, including aerospace, defense, and medical devices manufacturing. These industries require highly complex and reliable electronic components, and the new technology will help meet these requirements while reducing the production cost.Additionally, the new technology is expected to improve the overall energy efficiency of electronic devices. Today, energy efficiency is essential in various industries, and the new PCB technology is a significant step towards achieving this goal.PCB Making Company’s innovative approach to electronic components manufacturing is a testament to the company's commitment to providing the most advanced and effective solutions for its customers. With this new technology, PCB Making Company has set a new standard for the industry, and it is anticipated that other companies will follow suit.In conclusion, the development of the new PCB technology by PCB Making Company is a significant milestone in electronics manufacturing. The technology promises to offer a range of benefits, including reduced production cost, improved energy efficiency, and enhanced reliability. It is a testament to the company's commitment to innovation and providing the most advanced solutions for its customers.

Revolutionary Circuit Board Home Sparks Innovation and Efficiency

Circuit Board Manufacturer Leads the Way in Sustainable Manufacturing PracticesCircuit Board House (CBH) is a leading manufacturer of printed circuit boards that are used in a wide range of applications, including consumer electronics, automotive industry, computer hardware, and power supplies. The company has been providing high-quality PCB solutions to its clients for over two decades. However, what sets CBH apart from other manufacturers is its commitment to sustainability across all facets of its business operations.CBH understands that as a manufacturer, it has a responsibility to minimize its environmental impact and ensure that its operations are socially responsible. Therefore, the company has taken a proactive approach to addressing these issues by implementing several sustainable practices that reduce waste and improve efficiency.One of the key areas where CBH has made significant strides is in reducing its energy consumption. The company has invested in the installation of energy-efficient equipment and LED lighting in its facilities. This has resulted in a 20% reduction in electricity consumption, cutting the company's carbon footprint by around 1,000 tons per year. The company also recognizes the importance of water conservation and has implemented measures to reduce water usage in its operations.Another significant area of focus for CBH is waste reduction. The company has developed a comprehensive waste management program that includes recycling and reusing as much waste as possible, which has led to a 35% reduction in waste. For example, the company has implemented a strict inventory control system, reducing the amount of scrap material generated during production.In addition to its internal sustainable practices, CBH is committed to sustainable sourcing. The company has established partnerships with suppliers who share its values and who are committed to ethical and environmentally responsible practices. CBH also takes great pride in its employees, providing them with a safe and healthy workplace, along with a range of development and training opportunities.CBH recognizes that its efforts towards sustainability go beyond improving its own operations and extends towards creating a more sustainable industry. Therefore, it is actively engaged in industry associations and initiatives that promote sustainability. The company has also taken a leadership role in educating its clients on the importance of sustainable practices and how they can play a part in creating a more sustainable future.As a result of its commendable efforts, CBH has received several awards and recognitions for its sustainable practices. For example, the company has been awarded the ISO 14001:2015 certification, which acknowledges its commitment to environmental management.Overall, CBH is a company that understands the critical role that businesses play in creating a sustainable future. It has taken admirable steps towards reducing waste, conserving resources, and promoting sustainable practices both within its operations and throughout the broader industry. As the global demand for sustainable practices continues to grow, more companies could learn from CBH's exceptional practices and emulate its approach towards sustainability.

Understanding the PCB Development Process: From Design to Manufacturing

PCB Development Process for Manufacturing Advanced Technology ProductsThe PCB development process is a crucial step in the production of advanced technology products. PCB, or printed circuit board, serves as the foundation for connecting electronic components in a multitude of devices, from smartphones and computers to medical equipment and automotive systems. The development process requires careful planning, precise execution, and thorough testing to ensure the reliability and functionality of the final product.In this regard, {Company Name} is a leading manufacturer specializing in PCB development and production for various industries. The company has established a strong reputation for delivering high-quality PCB solutions that meet the demanding requirements of modern technology products. With state-of-the-art facilities and a team of experienced engineers, {Company Name} is committed to providing innovative PCB development processes that drive the advancement of technology.The PCB development process at {Company Name} begins with a comprehensive analysis of the customer's requirements and specifications. This initial phase involves close collaboration with the client to understand the intended application of the PCB and its performance expectations. Whether it's a complex multilayer PCB for a sophisticated electronic device or a simple single-layer board for a basic application, {Company Name} employs a customized approach to meet the unique needs of each project.Once the requirements are defined, the PCB design phase commences. {Company Name} utilizes advanced design software and simulation tools to create a schematic layout that incorporates the necessary components and connectivity for the specific application. The design team at {Company Name} leverages their expertise to optimize the layout for signal integrity, power distribution, and thermal management, ensuring the overall performance and reliability of the PCB.Upon finalizing the design, the development process transitions to the prototyping stage. {Company Name} utilizes rapid prototyping techniques to quickly produce a physical prototype of the PCB for testing and validation. This iterative process allows for the identification of any design flaws or performance issues, which can be addressed before moving into full-scale production. By actively engaging in prototyping, {Company Name} ensures that the final PCB meets the highest standards of quality and functionality.The manufacturing phase of the PCB development process is where {Company Name}'s expertise truly shines. With a focus on precision and efficiency, the company utilizes advanced manufacturing equipment and processes to fabricate the PCB according to the approved design. Whether it's the precise application of copper traces, the addition of vias and pads, or the implementation of specialized surface finishes, {Company Name} employs stringent quality control measures to maintain consistency and accuracy throughout the manufacturing process.To ensure the reliability and durability of the PCB, {Company Name} conducts thorough testing and inspection procedures. The company utilizes advanced testing equipment to validate the electrical performance, mechanical strength, and environmental resilience of the PCB. From electrical continuity and impedance testing to thermal cycling and vibration testing, {Company Name} enforces a comprehensive testing regime to validate the functionality and durability of the PCB for its intended application.With the PCB development process finalized, {Company Name} delivers the finished product to its customers with a commitment to excellence. The company's dedication to quality, innovation, and customer satisfaction has positioned it as a trusted partner for numerous industries seeking reliable PCB solutions. Whether it's for consumer electronics, automotive systems, medical devices, or industrial applications, {Company Name} continues to drive the advancement of technology through its exceptional PCB development processes.In conclusion, the PCB development process is an essential aspect of manufacturing advanced technology products, and {Company Name} excels in delivering comprehensive and reliable PCB solutions. With a focus on collaborative design, rapid prototyping, precise manufacturing, and thorough testing, {Company Name} remains at the forefront of PCB development, ensuring the performance and reliability of electronic devices across various industries.

The Impact of Internet of Things on Modern Technology

The Internet of Things (IOT) has been making waves in the tech industry, and the latest developments from {} have only added fuel to the fire. With their innovative approach to IOT technology, {} is quickly becoming a key player in the industry, and their latest announcements have only solidified their position in the market.{} is a leading tech company that specializes in IOT solutions for a wide range of industries. Their cutting-edge technology and innovative approach have helped them carve out a niche in the competitive IOT market. With a focus on creating seamless and efficient connections between devices, {} is changing the way we interact with technology.One of the key developments from {} is their new line of IOT devices that are designed to revolutionize the way we live and work. These devices are not only cutting-edge in terms of technology, but they also promise to make our lives easier and more efficient. From smart home devices to industrial IOT solutions, {} has a wide range of products that are designed to meet the needs of a variety of industries.One of the most exciting aspects of {}'s IOT technology is its potential to improve efficiency and streamline processes. By connecting devices and syncing data in real-time, {}'s IOT solutions can provide businesses with valuable insights and help them make more informed decisions. This can lead to cost savings, improved productivity, and better overall performance.In addition to their hardware offerings, {} also provides a range of software and services to help businesses integrate IOT technology into their operations. Their platform is designed to be intuitive and easy to use, making it accessible to businesses of all sizes. With {}'s IOT solutions, businesses can take advantage of the latest technology without the need for extensive technical knowledge or resources.One of the key factors that sets {} apart from other IOT providers is their commitment to security. With the increasing number of cyber threats, security is a top priority for businesses using IOT technology. {}'s IOT solutions are designed with security in mind, and they offer robust measures to protect against potential threats. This gives businesses peace of mind knowing that their data and devices are safe and secure.Another exciting development from {} is their work in the field of smart cities. By leveraging IOT technology, {} is helping to create more efficient and sustainable urban environments. From traffic management to waste management, {}'s IOT solutions are helping cities around the world operate more effectively and improve the quality of life for their residents.The future of IOT is bright, and {} is at the forefront of this exciting industry. With their innovative technology, commitment to security, and dedication to improving efficiency, {} is quickly becoming a key player in the IOT market. Their latest developments are proof of their dedication to providing cutting-edge solutions that make a real impact on businesses and communities.As IOT technology continues to evolve, {} will undoubtedly play a major role in shaping the future of this industry. Their dedication to innovation and their ability to create seamless connections between devices make them a force to be reckoned with. With {}'s IOT solutions, businesses can look forward to a more efficient and connected future.

Expert PCB Manufacturing Solutions in the Bay Area" becomes "Top-rated PCB Manufacturing in the Bay Area

Title: Pioneering PCB Manufacturing in the Bay Area Revolutionizes Electronic IndustryIntroduction:In the heart of the innovation hub that is the Bay Area, a leading manufacturer has emerged to disrupt the electronic industry. Through their cutting-edge facilities and commitment to quality, this company has quickly become a game-changer in the world of printed circuit board (PCB) manufacturing. With an unwavering dedication to innovation and customer satisfaction, this visionary manufacturer is establishing itself as a top-tier provider of PCB solutions.Body:1. The Bay Area's Thriving Electronics Landscape:The Bay Area has long been known as a hotbed for technology and innovation, with countless startups and established companies constantly pushing boundaries to create groundbreaking products. With the rise of Internet of Things (IoT) devices, wearables, autonomous vehicles, and advanced medical equipment, the demand for high-quality PCBs has skyrocketed. Recognizing this growth potential, our featured manufacturer entered the scene with a mission to fulfill the increasing demand for innovative PCB solutions.2. Advanced Manufacturing Facilities:The company boasts a state-of-the-art manufacturing facility in the heart of the Bay Area, equipped with cutting-edge machinery and technology. Committed to staying at the forefront of industry advancements, they continually invest in new equipment and software to ensure the highest level of precision, efficiency, and quality in their PCB manufacturing process.3. Embracing Industry Standards:Compliance with industry standards is paramount for any PCB manufacturer. This company exceeds expectations by adhering to stringent international standards, including ISO 9001, ISO 14001, and IPC Class 3. By maintaining these certifications, they ensure the manufacturing of PCBs that meet the highest quality and reliability standards.4. Emphasis on Research and Development:Innovation is the lifeblood of this pioneering manufacturer. To stay ahead of the curve, they place a strong emphasis on research and development, actively collaborating with industry partners and academic institutions to drive forward-thinking solutions. By fostering a culture of innovation and creativity, they continuously push the boundaries of PCB manufacturing, offering cutting-edge solutions to their customers.5. Diverse Product Range:With a customer-centric approach, this PCB manufacturer offers a diverse range of products to cater to various industries such as aerospace, automotive, consumer electronics, telecommunications, medical, and more. Whether it's single-sided, double-sided, flexible, or rigid-flex PCBs, they have the capabilities to provide tailored solutions to meet clients' specific requirements.6. Seamless Customer Experience:Understanding the importance of exceptional customer service, this manufacturer takes pride in offering a seamless experience from start to finish. From initial design consultation to final delivery, they are committed to providing timely communication, personalized attention, and technical guidance to ensure each client's unique needs are met.7. Eco-Friendly Practices:As responsible corporate citizens, the company places a strong emphasis on sustainability. They promote eco-friendly practices by optimizing production processes to minimize waste, recycling materials whenever possible, and reducing environmental impact. Their commitment to sustainability extends beyond manufacturing, ensuring that PCBs are produced ethically and responsibly.Conclusion:In the dynamic landscape of the Bay Area, PCB manufacturing has taken a significant leap forward with this visionary company's innovative approach. Their state-of-the-art manufacturing facilities, commitment to quality and industry standards, focus on research and development, diverse product range, seamless customer experience, and eco-friendly practices distinguish them as trailblazers. As they continue to redefine the boundaries of PCB manufacturing, their impact on the electronic industry becomes increasingly profound, cementing their status as a leading provider of cutting-edge PCB solutions in the Bay Area and beyond.

In-depth Analysis of the Latest PCB Specifications and Features

PCB Details[Company] is a leading manufacturer of high-quality printed circuit boards (PCBs) for various industries such as telecommunications, aerospace, medical devices, and automotive. The company has been in the industry for over a decade, and they have continuously invested in state-of-the-art technology and equipment to ensure the production of top-notch PCBs that meet the highest industry standards.The company's PCBs are known for their durability, reliability, and high performance, making them the preferred choice for many leading companies in different sectors. [Company] prides itself on its ability to customize PCBs according to the specific requirements of their clients, offering a wide range of materials, designs, and technologies to meet the diverse needs of their customers.One of the key factors that set [Company] apart from its competitors is its commitment to quality and excellence. The company has a rigorous quality control process in place, and every PCB undergoes thorough testing and inspection to ensure that it meets the strictest quality standards. This dedication to quality has earned [Company] a reputation for delivering PCBs that consistently exceed customer expectations.In addition to their commitment to quality, [Company] also places a strong emphasis on innovation and continuous improvement. The company's team of highly skilled engineers and technicians are constantly exploring new technologies and methodologies to enhance their PCB manufacturing process and develop new products that are on the cutting edge of technology.Recently, [Company] announced the launch of their latest PCB product line, which is designed to meet the growing demand for high-performance PCBs in the telecommunications and aerospace industries. The new PCBs feature advanced materials and construction techniques that offer superior reliability and performance, making them ideal for mission-critical applications where downtime is not an option.The new PCBs are also optimized for high-speed data transmission, making them well-suited for the increasing data demands of modern communication networks and aerospace systems. With the ability to handle high-frequency signals with minimal signal loss, these PCBs are poised to set a new standard for performance and reliability in their respective industries."We are excited to introduce our latest line of PCBs, which represents the culmination of years of research and development aimed at pushing the boundaries of what is possible in PCB technology," said [Company]'s CEO. "These new PCBs are a testament to our commitment to innovation and excellence, and we are confident that they will provide our customers with a competitive edge in their respective markets."The launch of the new PCB product line is expected to further solidify [Company]'s position as a leading PCB manufacturer and supplier in the industry. With their proven track record of delivering high-quality, reliable PCBs, and their ongoing commitment to innovation and excellence, [Company] is well-positioned to continue serving the evolving needs of their customers across various sectors.The company's dedication to quality, innovation, and customer satisfaction has earned them a strong reputation in the industry, and they are poised for further growth and success in the years to come. As the demand for high-performance PCBs continues to rise, [Company] remains at the forefront of the industry, providing cutting-edge solutions that empower their customers to succeed in an increasingly competitive market.

How to Order a PCB: A Complete Guide

The demand for high-quality printed circuit boards (PCBs) is on the rise, and one company has been meeting this demand with top-tier products and exceptional service. With a commitment to excellence and a focus on customer satisfaction, {Company Name} has established itself as a leader in the PCB manufacturing industry.{Company Name} is known for its state-of-the-art facility, advanced technology, and skilled team of professionals. With years of experience in the industry, the company has honed its expertise in the design, fabrication, and assembly of PCBs for a wide range of applications. Whether it's for automotive, aerospace, medical, or consumer electronics, {Company Name} has the capabilities to deliver PCBs that meet the highest standards of quality and reliability.In addition to its manufacturing capabilities, {Company Name} also offers a range of value-added services to its customers. From design consultation and prototyping to full-scale production and testing, the company takes a comprehensive approach to PCB manufacturing to ensure that its customers' exact needs are met. This dedication to providing end-to-end solutions has earned {Company Name} a reputation for being a trusted partner in the industry.With a customer-centric approach, {Company Name} is committed to delivering PCBs that not only meet technical specifications but also exceed customer expectations. The company prides itself on its ability to collaborate closely with customers, understanding their unique requirements, and providing tailored solutions that address their specific challenges. This personalized approach has allowed {Company Name} to build lasting relationships with its customers and earn their loyalty.In response to the growing demand for its products and services, {Company Name} has recently announced the launch of its online PCB ordering platform. This new initiative aims to streamline the process of ordering PCBs, making it easier and more convenient for customers to access {Company Name}'s industry-leading products. By offering a user-friendly interface, instant quotations, and efficient order processing, the online platform is set to enhance the overall customer experience and further solidify {Company Name}'s position as a leader in the industry.Customers who utilize the online ordering platform can expect the same level of quality and attention to detail that {Company Name} is known for. With a seamless and efficient ordering process, customers can place their orders with confidence, knowing that they will receive PCBs that adhere to the highest standards of performance and reliability. This new initiative is a testament to {Company Name}'s commitment to innovation and continuous improvement in serving its customers.In addition to the online ordering platform, {Company Name} continues to invest in its manufacturing capabilities to meet the evolving needs of the industry. The company's ongoing investment in technology and infrastructure ensures that it remains at the forefront of PCB manufacturing, offering cutting-edge solutions that are tailored to the demands of today's ever-changing market.As {Company Name} continues to expand its presence in the PCB manufacturing industry, it remains steadfast in its dedication to providing exceptional products and services to its customers. With a focus on quality, innovation, and customer satisfaction, {Company Name} is poised to continue its leadership in the industry, setting new standards for excellence in PCB manufacturing.In conclusion, with its strong commitment to excellence and customer satisfaction, {Company Name} has become a trusted name in the PCB manufacturing industry. Through its advanced technology, skilled team, and customer-centric approach, the company has earned a reputation for delivering top-tier PCBs and exceptional service. With the launch of its online ordering platform and ongoing investment in manufacturing capabilities, {Company Name} is well-positioned to meet the evolving needs of the industry and continue its legacy of excellence in PCB manufacturing.