New development in the tech industry: Company Smt Ems reveals latest update

By:Admin

Smt Ems is a globally recognized electronics manufacturing services provider, offering a wide range of solutions to meet the needs of various industries. With a strong focus on quality, efficiency, and innovation, Smt Ems has established itself as a leader in the electronics manufacturing sector. The company's cutting-edge technologies and advanced manufacturing processes have made it a preferred partner for many businesses looking to develop high-quality electronic products.

The semiconductor company, on the other hand, is renowned for its expertise in the design and manufacturing of semiconductor products. With a strong track record of delivering high-performance and reliable components, the semiconductor company has become a trusted partner for many organizations seeking to integrate advanced semiconductor technology into their products.

The partnership between Smt Ems and the semiconductor company marks a significant milestone for both organizations. By combining their respective strengths and capabilities, the two companies aim to develop new and innovative electronic solutions that will set new standards in the industry. This collaboration will leverage the semiconductor company's cutting-edge technology and Smt Ems' advanced manufacturing processes to create a range of high-quality electronic products that will cater to the evolving needs of the market.

One of the key objectives of the partnership is to develop next-generation electronic products that are highly efficient, reliable, and cost-effective. By harnessing the synergies between their technologies and expertise, Smt Ems and the semiconductor company aim to address the growing demand for electronic solutions that offer superior performance and durability. The collaboration will also focus on driving innovation in the electronics industry by introducing new features, functionalities, and applications that will enhance the overall user experience.

Furthermore, the partnership will enable both companies to expand their market reach and penetrate new segments. By leveraging each other's strengths and resources, Smt Ems and the semiconductor company will be able to offer a wider range of electronic solutions to a diverse set of customers. This will enable them to capitalize on emerging market opportunities and strengthen their position as leading providers of electronic products and services.

In addition to product development, the partnership will also focus on enhancing the sustainability of electronic manufacturing processes. Both Smt Ems and the semiconductor company are committed to adopting environmentally-friendly practices and minimizing the environmental impact of their operations. By working together, the two organizations will be able to develop and implement sustainable manufacturing solutions that reduce waste, energy consumption, and carbon emissions.

Overall, the partnership between Smt Ems and the semiconductor company holds great promise for the electronics industry. By combining their expertise, resources, and technologies, the two companies aim to develop innovative electronic solutions that will set new standards in terms of performance, reliability, and sustainability. With a focus on driving innovation and meeting the evolving needs of the market, this collaboration is set to bring forth a new era of electronic products that will benefit businesses and consumers alike.

Company News & Blog

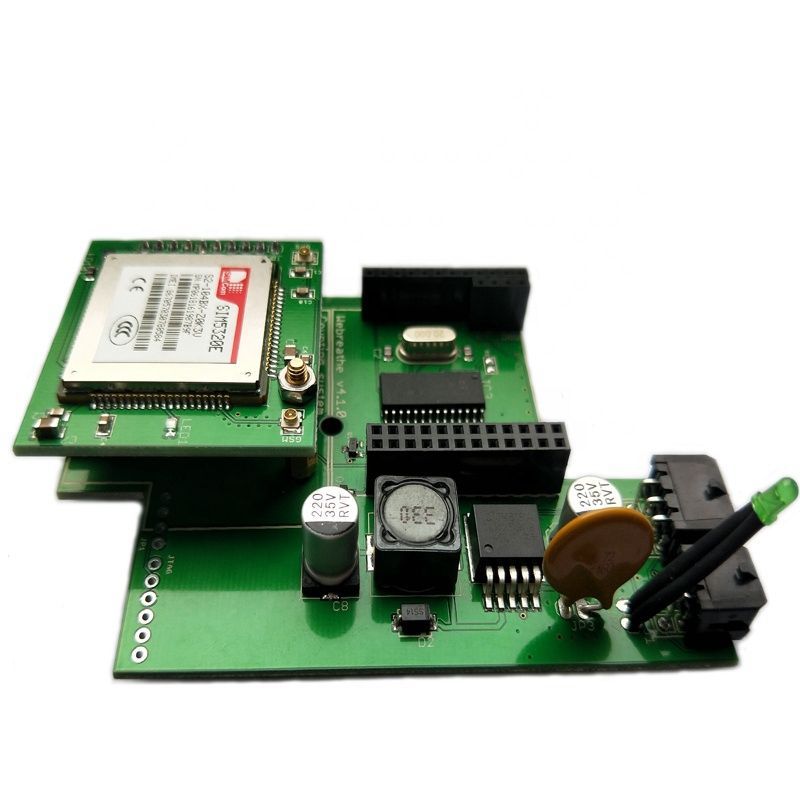

Cutting-Edge Single PCB Technology Revolutionizes Electronic Manufacturing Process

In the world of electronics, printed circuit boards (PCBs) have become the go-to solution for creating complex and intricate circuits. However, the traditional process of designing and manufacturing PCBs involves multiple steps, which can take up a significant amount of time and resources. However, that is all changing with the emergence of Single PCB, a revolutionary technology that promises to reduce the complexity and cost of PCB design and manufacturing.Single PCB is a brand new technology that allows for the creation of PCBs in a single step. This means that designers can create entire circuits using just a single board, which saves time and resources. Additionally, this technology eliminates the need for multiple components, reducing the overall cost of PCB production.At the forefront of this technology is a company, whose innovative single PCB technology has the potential to revolutionize the electronics industry. With over a decade of experience in PCB design and manufacturing, this company has developed a comprehensive range of solutions that has set it apart from its competitors.Headquartered in [city, country], the company prides itself on being a leading provider of PCB related services and solutions. With a team of highly skilled and experienced professionals, the company has built a reputation for excellence in the industry.The company's single PCB technology is the result of years of research and development. The technology has been specifically designed to simplify the process of PCB design and production, making it more accessible to a wider range of users.One of the biggest advantages of the single PCB technology is its ability to reduce the complexity of the design process. With traditional PCB manufacturing, designers had to create multiple boards and then connect them using a variety of connectors and wires. This process was time-consuming, and there was always the risk of errors occurring during assembly. However, with the single PCB technology, designers can create an entire circuit on a single board, eliminating the need for additional components and saving time and money.Another important benefit of the single PCB technology is the reduction in the overall cost of PCB production. With traditional PCB manufacturing, there were multiple steps involved, including designing the boards, assembling the components, and testing the finished product. However, with single PCB technology, the entire process can be completed in a single step, reducing the overall cost of production.The single PCB technology has also been designed with flexibility in mind. This means that designers can create circuits of varying complexity, adapting the technology to suit their specific needs. Additionally, the technology can be used to create a wide range of products, from simple electronic toys to complex medical equipment.As the world becomes more reliant on technology, the demand for innovative and efficient PCB manufacturing solutions is only going to increase. Single PCB technology is poised to meet this demand head-on, offering a simple and cost-effective solution for creating cutting-edge electronic products.In conclusion, the emergence of Single PCB technology is a game-changer for the electronics industry. With its simplified design process, reduced manufacturing costs, and flexibility, this technology has the potential to reshape the way we design and manufacture electronic products. The company behind this technology is poised to lead the way in the single PCB market, offering customers a comprehensive range of solutions that are designed to meet their specific needs and requirements.

Essential Guide to FPC Circuit: What You Need to Know

FPC Circuit, also known as flexible printed circuit, is a type of electronic circuit that is manufactured using a flexible substrate material such as polyimide or polyester. These circuits are known for their flexibility, lightweight, and space-saving design, making them ideal for a range of electronic applications including consumer electronics, medical devices, and automotive components.{} is a leading manufacturer and supplier of flexible printed circuits, with a strong focus on quality, innovation, and customer satisfaction. With over 20 years of experience in the industry, the company has established itself as a trusted partner for many global electronics companies, providing high-quality FPC circuits that meet the specific requirements of each customer.The company's state-of-the-art production facilities are equipped with the latest technology and machinery to ensure the highest standards of quality and precision in every FPC circuit manufactured. From single-sided to multi-layered circuits, {} offers a wide range of options to meet the diverse needs of its customers.In addition to its manufacturing capabilities, {} also offers comprehensive design and engineering services to support customers in the development of customized FPC circuits. The company's team of highly skilled engineers and technicians work closely with customers to understand their unique requirements and provide innovative solutions that meet or exceed their expectations.{}'s commitment to quality and excellence has earned it a strong reputation in the industry, with a track record of delivering reliable and high-performance FPC circuits to customers worldwide. The company's dedication to continuous improvement and innovation has enabled it to stay ahead of the curve in a rapidly evolving industry, consistently providing cutting-edge solutions that meet the demands of the market.As the demand for flexible printed circuits continues to grow across various industries, {} remains at the forefront of the industry, continuously investing in research and development to explore new technologies and materials that will further enhance the performance and versatility of FPC circuits.With a strong emphasis on customer satisfaction, {} strives to build long-term partnerships with its customers by offering unrivaled technical support, timely delivery, and competitive pricing. The company's dedication to meeting and exceeding customer expectations has been a key factor in its success, earning it the trust and loyalty of a growing base of satisfied customers.Looking ahead, {} is poised to continue its leadership in the FPC circuit industry, leveraging its expertise, capabilities, and commitment to innovation to drive the development of new and advanced solutions that will shape the future of electronics technology.In conclusion, {} is a trusted and leading provider of flexible printed circuits, offering a comprehensive range of high-quality products and services to meet the diverse needs of its global customer base. With a strong focus on quality, innovation, and customer satisfaction, the company is well-positioned to continue its success and drive the advancement of FPC circuits in the electronics industry.

Top Tips for Choosing a Reliable PCB Board Manufacturer

PCB Board House, a leading manufacturer of printed circuit boards (PCBs), has been making waves in the electronics industry with its high-quality products and exceptional customer service. The company has been a key player in the PCB manufacturing industry for over a decade and has built a reputation for its state-of-the-art facilities and expertise in producing complex PCBs for a wide range of applications.Established in [year], PCB Board House has continuously invested in the latest technology and equipment to ensure that it stays at the forefront of PCB manufacturing. The company prides itself on its ability to deliver high-quality PCBs within tight deadlines, making it a trusted partner for many businesses in various industries, including aerospace, medical, automotive, and telecommunications.With a team of highly skilled engineers and technicians, PCB Board House is capable of producing PCBs in various designs, materials, and sizes to meet the specific requirements of its customers. The company offers a comprehensive range of services, including PCB layout design, prototype assembly, and full-scale production, all of which are carried out with the utmost precision and attention to detail.In addition to its commitment to quality and innovation, PCB Board House places a strong emphasis on environmental sustainability. The company adheres to strict environmental standards and practices responsible waste management to minimize its ecological footprint. Furthermore, PCB Board House continuously explores eco-friendly materials and processes to ensure that its products are in line with the latest sustainability guidelines.Recently, PCB Board House made headlines with the launch of its latest line of advanced PCBs, designed to meet the increasing demands of the electronics market. The company's new range of PCBs boasts enhanced durability, reliability, and performance, making them ideal for use in cutting-edge electronic devices and systems. Leveraging its expertise and state-of-the-art facilities, PCB Board House has successfully developed PCBs that can withstand extreme temperatures, vibrations, and corrosive environments, catering to the needs of industries where ruggedness and resilience are critical.In response to the growing demand for IoT devices and smart technologies, PCB Board House has also expanded its capabilities to produce high-density interconnect (HDI) PCBs with superior signal integrity and miniaturization. These advanced PCBs are essential for the development of next-generation electronics, including wearables, 5G infrastructure, and autonomous vehicles, where space and performance are of utmost importance.Furthermore, PCB Board House has been proactive in fostering strategic partnerships with leading technology companies to stay ahead of the curve in the rapidly evolving electronics landscape. By collaborating with industry leaders, the company gains access to cutting-edge technologies, trends, and best practices, enabling it to deliver innovative solutions that meet the most demanding requirements of its customers.As a testament to its commitment to excellence, PCB Board House has obtained various industry certifications, including ISO 9001, ISO 14001, and UL, affirming its dedication to upholding the highest standards of quality, safety, and environmental management. These certifications underscore the company's unwavering commitment to delivering superior products and services while prioritizing the well-being of its employees and the environment.Looking ahead, PCB Board House is poised to continue its expansion and explore new frontiers in PCB manufacturing, driven by its relentless pursuit of innovation and customer satisfaction. As the demand for advanced electronics continues to grow, PCB Board House remains steadfast in its mission to be the go-to partner for companies seeking exceptional PCB solutions that push the boundaries of technology and performance.In conclusion, PCB Board House has established itself as a leading force in the PCB manufacturing industry, setting the standard for excellence and reliability. With its unwavering dedication to quality, innovation, and customer satisfaction, the company is well-positioned to meet the evolving needs of the electronics market and drive the future of PCB technology.

How to Prototype and Manufacture PCBs for Your Next Project

[Company Name], a leading manufacturer of electronic components and PCB (Printed Circuit Board) prototypes, has announced the launch of their latest product, the Prototyp PCB. This cutting-edge PCB prototype offers innovative features and advanced technology that set it apart from other products on the market.The Prototyp PCB is designed to meet the diverse needs of electronic engineers, hobbyists, and businesses looking to develop new electronic products. With its high-quality materials and precise manufacturing process, the Prototyp PCB ensures reliable performance and durability. The product is also known for its fast turnaround time, making it ideal for prototyping and testing new electronic designs.One of the key features of the Prototyp PCB is its versatility. The product supports a wide range of applications, including consumer electronics, automotive systems, medical devices, industrial equipment, and more. This flexibility makes it an excellent choice for engineers and designers working on various projects in different industries.In addition to its versatility, the Prototyp PCB offers excellent performance and functionality. The product is engineered to deliver high-speed data processing, low power consumption, and strong signal integrity, ensuring that electronic devices built with this PCB prototype will perform efficiently and reliably.[Company Name] has a proven track record of delivering high-quality electronic components and PCB prototypes to its customers. The company's team of expert engineers and technicians are dedicated to providing top-notch products and exceptional customer service. With state-of-the-art facilities and advanced manufacturing capabilities, [Company Name] is able to produce the Prototyp PCB with strict quality control measures in place, ensuring that each prototype meets the highest standards of excellence.The launch of the Prototyp PCB demonstrates [Company Name]'s commitment to innovation and continuous improvement. The company is dedicated to staying at the forefront of technology and offering cutting-edge solutions to meet the evolving needs of the electronics industry. By investing in research and development, [Company Name] is able to develop products like the Prototyp PCB that push the boundaries of what is possible in electronic design and manufacturing.Customers who choose the Prototyp PCB can expect to benefit from its high performance, reliability, and cost-effectiveness. The product's competitive pricing and quick turnaround time make it a practical choice for businesses and individuals looking to bring their electronic designs to life. With the Prototyp PCB, customers can save time and money without compromising on quality.As the electronics industry continues to evolve, [Company Name] remains committed to providing innovative solutions that empower engineers, designers, and businesses to bring their electronic innovations to market. The Prototyp PCB is the latest example of [Company Name]'s dedication to supporting the success of its customers and shaping the future of electronic design and manufacturing.In conclusion, the launch of the Prototyp PCB represents a significant milestone for [Company Name] and the electronics industry as a whole. The product's advanced features, versatile applications, and reliable performance make it an exceptional choice for anyone looking to prototype and test electronic designs. With [Company Name]'s commitment to quality and innovation, the Prototyp PCB is set to make a lasting impact on the electronic industry and empower customers to achieve their electronic design goals.

High-Quality Rapid Prototype PCB Board Manufacturing Services Available

Fast Turn Prototype PCB Board, a leading provider of high-quality printed circuit boards, is pleased to announce the launch of their latest product, the Fast Turn Prototype PCB Board. This new offering is designed to meet the growing demand for fast turnaround times and high-quality prototypes in the electronic manufacturing industry.With the increasing pace of technology development, companies are under pressure to bring new products to market quickly. This is especially true for smaller companies and startups that are looking to stay ahead of the competition. Fast Turn Prototype PCB Board understands the needs of these companies and has developed a product that can help them achieve their goals.The Fast Turn Prototype PCB Board is designed to be produced in a short amount of time without sacrificing quality. This is achieved through a combination of advanced manufacturing processes and a focus on efficiency. The company utilizes state-of-the-art equipment and production techniques to ensure that each prototype PCB board meets the highest standards of quality and reliability.In addition to fast turnaround times, the Fast Turn Prototype PCB Board also offers a high degree of customization. This allows companies to quickly iterate on their designs and make changes as needed, without having to wait for long lead times. The ability to rapidly prototype and test new designs is crucial for companies looking to innovate and stay ahead of the curve.One of the key advantages of the Fast Turn Prototype PCB Board is its ability to reduce time-to-market for new products. By streamlining the prototyping process, companies can bring their ideas from concept to reality in a fraction of the time it would take with traditional PCB manufacturing methods. This allows companies to get their products into the hands of customers faster, gaining a competitive edge in the market.The Fast Turn Prototype PCB Board is also suitable for a wide range of applications, including consumer electronics, automotive, medical devices, and more. The company offers a variety of materials and finishes to meet the specific needs of each application, ensuring that the end product meets the required performance and reliability standards.Fast Turn Prototype PCB Board is committed to providing the highest level of customer service and support. The company's team of experts is available to help customers at every stage of the prototyping process, from design assistance to troubleshooting and technical support. This level of support ensures that customers can move quickly through the prototyping process and get their products to market as soon as possible."We are excited to introduce the Fast Turn Prototype PCB Board to the market," said [Company Spokesperson]. "We understand the challenges that companies face in bringing new products to market quickly, and our new offering is designed to address these challenges head-on. With our fast turnaround times and high-quality prototypes, we are confident that the Fast Turn Prototype PCB Board will become an essential tool for companies looking to innovate and succeed in today's fast-paced electronic manufacturing industry."For companies looking to accelerate their product development cycle and get their ideas to market quickly, the Fast Turn Prototype PCB Board is the ideal solution. With its combination of fast turnaround times, high quality, and customization options, this new offering from Fast Turn Prototype PCB Board is poised to revolutionize the prototyping process and help companies stay ahead of the competition.

Design for Manufacturing for Printed Circuit Boards: A Complete Guide

PCB manufacturing is a critical part of the electronics industry, and the demand for high-quality and reliable PCBs is ever-increasing. Companies are constantly looking for ways to improve the design and production of their PCBs to meet the growing demands of the market. One important aspect of PCB production is the use of Design for Manufacturability (DFM) techniques to ensure that the PCBs are manufactured efficiently and cost-effectively.DFM for PCB is a set of guidelines and best practices that are used to optimize the design and manufacturing process of PCBs. By incorporating DFM principles into the design phase, companies can minimize production costs, reduce the time to market, and improve the overall quality of the PCBs.One company that has been at the forefront of implementing DFM for PCB is {}. With a strong focus on innovation and technology, {} has been a leader in the PCB manufacturing industry for over [X] years. The company has a proven track record of delivering high-quality and reliable PCBs to a wide range of customers across different industries.{} has invested heavily in state-of-the-art manufacturing facilities and has a team of highly skilled engineers and technicians who are constantly exploring new ways to improve the design and production of PCBs. By leveraging the latest DFM techniques, {} has been able to streamline its production process, reduce waste, and improve overall efficiency.One of the key benefits of using DFM for PCB is that it allows companies to identify and address potential manufacturing issues at an early stage of the design process. By considering manufacturability from the outset, companies can make design adjustments that not only improve the overall quality of the PCBs but also reduce the manufacturing complexity, which ultimately leads to cost savings.Another important aspect of DFM for PCB is the ability to optimize the use of materials and components. By carefully considering the selection of materials and components, companies can reduce material waste and ultimately lower production costs. This is especially important in today's competitive market, where companies are under constant pressure to reduce costs while maintaining high-quality standards.Additionally, DFM for PCB also takes into account the production capabilities of the manufacturing process. By understanding the limitations and capabilities of the production process, companies can make design decisions that are aligned with the manufacturing capabilities, ultimately leading to smoother production and higher-quality PCBs.In conclusion, DFM for PCB is an essential aspect of modern PCB manufacturing. Companies like {} that have embraced DFM principles have been able to improve their production processes, reduce costs, and deliver high-quality PCBs to their customers. As the demand for PCBs continues to grow, it is likely that DFM techniques will become even more important in ensuring the efficient and cost-effective production of PCBs.

What Are the Differences Between SMT and SMD Components?

SMT and SMD Technology Revolutionizing Electronic ManufacturingIn the fast-paced world of electronic manufacturing, Surface Mount Technology (SMT) and Surface Mount Device (SMD) have revolutionized the way electronic components are mounted onto circuit boards. These advancements have allowed for increased efficiency, improved performance, and reduced manufacturing costs, making them essential components of modern electronic production processes.SMT is a method of electronic component assembly that utilizes automated machines to place components onto the surface of a printed circuit board (PCB). This technology has largely replaced the older through-hole technology, which required components to be inserted into holes drilled through the PCB and then soldered in place. SMT has significantly reduced the size of electronic devices while increasing their functionality and reliability.SMD refers to the actual components that are mounted onto the PCB using SMT. These components are specially designed to be compact and lightweight, making them ideal for use in modern electronic devices. SMD components include resistors, capacitors, diodes, and integrated circuits, among others. These components play a critical role in the functionality of electronic devices, and their small size allows for densely populated PCBs without sacrificing performance.The company {}, founded in 1995, has been at the forefront of the SMT and SMD revolution, supplying high-quality components and manufacturing equipment to electronic manufacturers worldwide. The company offers a comprehensive range of SMD components, including resistors, capacitors, diodes, and integrated circuits, as well as a variety of SMT manufacturing equipment such as pick-and-place machines, soldering equipment, and inspection systems.With a focus on innovation and quality, {} has become a trusted partner for electronic manufacturers looking to maximize efficiency and performance while reducing production costs. The company's dedication to providing cutting-edge technology and superior customer service has earned them a reputation as a leading provider in the electronic manufacturing industry.In addition to providing SMD components and manufacturing equipment, {} also offers comprehensive support and training programs to help manufacturers integrate SMT and SMD technology into their production processes. This ensures that customers are able to fully utilize the benefits of this advanced technology, resulting in improved product quality and increased profitability.As electronic devices continue to become smaller, more powerful, and more complex, the demand for SMT and SMD technology is expected to grow. Manufacturers are constantly striving to increase the performance and functionality of their products, while also reducing production costs. SMT and SMD technology have proven to be essential in meeting these demands, and companies like {} are at the forefront of driving this innovation forward.With a commitment to excellence and a focus on continuous improvement, {} is poised to continue leading the way in the SMT and SMD industry, providing manufacturers with the tools and expertise they need to succeed in an increasingly competitive market.In conclusion, SMT and SMD technology have significantly transformed the electronic manufacturing industry, leading to smaller, more powerful, and more reliable electronic devices. As the demand for advanced electronic products continues to grow, the importance of SMT and SMD technology will only continue to increase. With companies like {} driving innovation and providing comprehensive solutions, the future of electronic manufacturing looks brighter than ever.

How Multiple Layer PCBs Are Revolutionizing Electronic Devices

[Company Name], a leading provider of electronic manufacturing services, is proud to announce the launch of its new product, the Multiple Layer PCB. This innovative technology is set to revolutionize the electronics industry with its advanced features and capabilities.The Multiple Layer PCB is designed to meet the increasing demand for more complex and compact electronic devices. With the rising trend of miniaturization, electronic manufacturers are seeking solutions that can accommodate more components in a smaller space without compromising on performance. This is where the Multiple Layer PCB comes into play, offering a high-density interconnect solution that allows for the integration of more components on a single board.One of the key features of the Multiple Layer PCB is its ability to support multiple layers of conductive traces, which allows for greater routing flexibility and increased component density. This enables electronic devices to be more compact and lightweight, while also enhancing their overall performance. Furthermore, the Multiple Layer PCB is designed to offer excellent signal integrity, power distribution, and thermal management, making it suitable for a wide range of applications, including consumer electronics, automotive systems, medical devices, and industrial equipment.In addition to its technical capabilities, the Multiple Layer PCB is also manufactured using high-quality materials and advanced processes to ensure maximum reliability and consistency. It is built to withstand harsh operating conditions, such as temperature fluctuations, moisture, and mechanical stress, which makes it ideal for mission-critical applications where reliability is paramount.As a company committed to innovation and excellence, [Company Name] has invested heavily in research and development to bring the Multiple Layer PCB to market. The company's state-of-the-art manufacturing facilities and experienced engineering team have played a crucial role in the development and optimization of this groundbreaking technology. With a strong focus on quality and customer satisfaction, [Company Name] is dedicated to delivering the highest level of performance and reliability with its products."We are thrilled to introduce the Multiple Layer PCB to the market," said [Company CEO]. "This new technology represents a significant leap forward in the field of electronic manufacturing, and we believe it will set new standards for performance, reliability, and compactness. We are confident that the Multiple Layer PCB will enable our customers to design and build the next generation of electronic devices that are smaller, more powerful, and more efficient than ever before."The launch of the Multiple Layer PCB is a testament to [Company Name]'s commitment to staying at the forefront of technological advancements in the electronics industry. The company continues to invest in research and development to drive innovation and meet the evolving needs of its customers. With its comprehensive range of electronic manufacturing services and cutting-edge solutions, [Company Name] is well-positioned to empower businesses to bring their most ambitious ideas to life.In conclusion, the introduction of the Multiple Layer PCB marks a significant milestone for [Company Name] and the electronics industry as a whole. With its advanced capabilities, reliability, and compact design, this new technology is poised to drive the next wave of innovation in electronic manufacturing. As [Company Name] continues to push the boundaries of what is possible, it reaffirms its commitment to delivering excellence and value to its customers.

Get Quality PCB Assembly Services for Your Electronic Products

In recent years, the global electronics industry has been on an upward trajectory, with the market expected to reach $2.2 trillion by 2025. This growth has been fueled by rising demand for electronic devices, including smartphones, laptops, and smart home gadgets.As a key player in the electronics industry, PCB assembly services have become more important than ever. PCB assembly services provide companies with high-quality, reliable circuit board assembly that supports their business goals while also ensuring product longevity and customer satisfaction.One company that is making waves in the world of PCB assembly services is {}, a leading manufacturer of high-performance PCB assembly solutions. Comprised of professionals with extensive experience in PCB assembly, the company has built a solid reputation for delivering flexible, customized PCB assembly solutions that meet the unique requirements of each client.{"}'s PCB assembly services are backed by state-of-the-art technology and a team of highly qualified engineers who utilize advanced equipment such as SMT machines, automatic optical inspection (AOI) systems, and flying probe testers to streamline the production process and ensure high quality output.The company provides a wide range of PCB assembly services, including surface mount technology (SMT) assembly, through-hole assembly, and mixed technology assembly, ensuring that clients can choose the ideal assembly method required to meet the standards and specifications of their projects.With {}'s turnkey PCB assembly services, clients do not have to worry about managing every aspect of the project. The company provides a complete range of services, from conceptualization to product delivery, such as PCB layout design, PCB fabrication, component sourcing, and PCB assembly.One of the key benefits of choosing {} as your PCB assembly service partner is that they adhere to the highest industry standards. The company is certified to ISO 9001:2015, which guarantees customers that their products are manufactured according to international standards. Moreover, {} also complies with industry standards such as IPC-610 and IPC-A-600, ensuring that their clients receive the best quality possible.In addition to adhering to high industry standards, the company also offers competitive pricing and fast turnaround times. By streamlining the PCB assembly process and using cutting-edge technology, the company is able to support clients in reducing time-to-market, lowering costs, and improving process efficiency.To ensure that PCB assembly projects are executed smoothly, {} works closely with clients to understand their unique requirements, challenges, and goals. The company also provides a dedicated team of account managers who serve as the primary point of contact for clients, providing timely updates and support throughout the project's lifecycle.In conclusion, PCB assembly services are integral to the electronics industry, and companies that choose {} enjoy numerous benefits. From high-quality output to competitive pricing and fast turnaround times, {} offers a complete range of services that meet the unique requirements of each client.For those looking to collaborate with a PCB assembly service provider that adheres to high industry standards and provides customized solutions, {} is the ideal partner.

Ultimate Guide to PCB Assembly Process: Step-by-Step and Future Trends

In the world of electronics manufacturing, the PCB assembly process is a crucial step in bringing electronic devices to life. PCB, or printed circuit board, is the foundation of almost all electronic products and is used to mechanically support and electrically connect electronic components.The PCB assembly process involves several key steps, including solder paste application, component placement, reflow soldering, and inspection. Each step requires precision and attention to detail to ensure that the final product meets quality standards and functions as intended.One company that has excelled in the PCB assembly process is {}. With a strong focus on innovation and quality, {} has established itself as a leading provider of electronic manufacturing services. The company's state-of-the-art facilities and highly skilled engineers enable them to deliver high-quality PCB assembly services to a wide range of industries, including automotive, consumer electronics, and telecommunications.The first step in the PCB assembly process is the application of solder paste to the PCB. The solder paste, a mixture of tiny solder particles and flux, is applied to the board using a stencil. This step requires precision to ensure that the right amount of solder paste is deposited in the correct locations on the PCB.Once the solder paste is applied, the next step is component placement. This involves placing electronic components, such as resistors, capacitors, and integrated circuits, onto the PCB. {} utilizes advanced automated equipment for component placement, ensuring accuracy and efficiency in this crucial step of the assembly process.After the components are placed, the PCB undergoes reflow soldering. In this step, the PCB is heated in a controlled manner to melt the solder paste and create a permanent bond between the components and the board. The reflow soldering process must be carefully monitored to prevent defects such as solder bridges or incomplete solder joints.Following reflow soldering, the assembled PCB undergoes thorough inspection to ensure that all components are correctly placed and soldered. {} utilizes advanced inspection equipment, including automated optical inspection (AOI) and X-ray inspection, to identify any potential defects and ensure the highest quality standards are met.{}'s commitment to quality and innovation is evident in every step of the PCB assembly process. The company's dedication to continuous improvement and investment in advanced manufacturing technologies has positioned them as a trusted partner for electronic manufacturing services.The company's expertise in PCB assembly extends to both prototype and mass production quantities, catering to the diverse needs of their clients. Whether it's a complex multi-layer PCB for a cutting-edge electronic device or a simple single-layer board for a consumer product, {} has the capabilities and expertise to deliver high-quality results.In addition to PCB assembly, {} offers a full range of complementary services, including PCB design, testing, and supply chain management. This comprehensive approach allows the company to provide end-to-end solutions to their clients, from initial concept to final product delivery.With a strong track record of delivering high-quality PCB assembly services, {} continues to be a preferred partner for a wide range of industries. Their dedication to excellence, commitment to innovation, and relentless pursuit of customer satisfaction make them a leader in the electronics manufacturing industry.As the demand for electronic products continues to grow, the importance of a reliable and skilled PCB assembly partner cannot be understated. With {}'s expertise and capabilities, clients can be confident that their electronic products are in good hands, from design to production.