Top-quality PCB Manufacturer Provides Latest News Content

By:Admin

Founded in 2005, Rayming Pcb has quickly grown to become a trusted partner for businesses in various sectors, including telecommunications, automotive, aerospace, and consumer electronics. The company's commitment to quality and reliability has earned them a solid reputation within the industry.

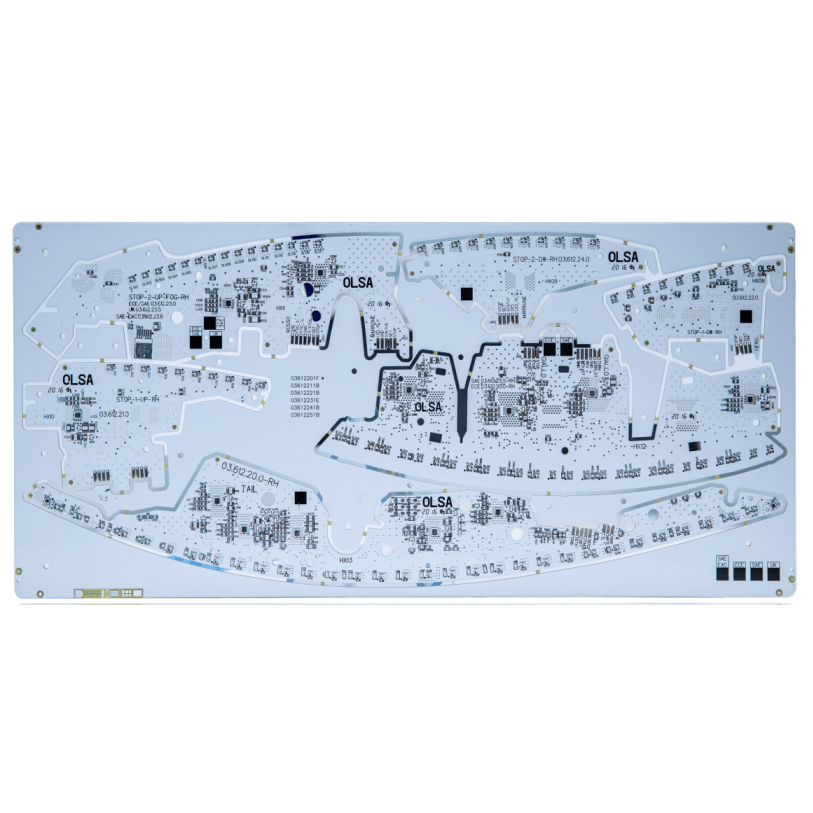

One of the key factors contributing to the success of Rayming Pcb is their state-of-the-art production facilities. Equipped with the latest machinery and technology, the company is capable of producing a wide range of PCBs, including rigid, flex, and rigid-flex boards. This allows them to meet the diverse needs of their clients and deliver customized solutions that meet the highest industry standards.

In addition to their advanced manufacturing capabilities, the company also places a strong emphasis on research and development. By investing in new technologies and processes, Rayming Pcb stays ahead of the curve and continuously improves their products to meet the evolving demands of the market. This dedication to innovation has positioned them as a leader in the development of cutting-edge PCB solutions.

Furthermore, Rayming Pcb is committed to sustainability and environmental responsibility. They adhere to strict environmental standards in their manufacturing processes and continuously seek ways to minimize their ecological footprint. This commitment to sustainability not only benefits the environment but also ensures that their products are in line with the growing demand for eco-friendly solutions.

The company’s recent announcement of new developments in their production capabilities further demonstrates their commitment to staying at the forefront of the industry. By continuously investing in new machinery and processes, they aim to enhance their production efficiency and expand their product offerings. This will allow them to better serve their clients and meet the increasing demand for high-quality PCBs.

One of the key updates to their production capabilities is the integration of advanced automation systems. By implementing cutting-edge robotics and automation technology, Rayming Pcb aims to streamline their manufacturing processes and improve overall efficiency. This will not only increase their production capacity but also ensure consistent quality across all their products.

In addition to automation, the company has also introduced new manufacturing techniques that allow for the production of more complex and advanced PCB designs. This includes the ability to create ultra-thin boards, high-density interconnects, and other intricate designs that are essential for the development of modern electronics.

Furthermore, Rayming Pcb has expanded their capabilities in producing flexible and rigid-flex PCBs, which are increasingly in demand for applications such as wearable devices, medical equipment, and automotive electronics. By investing in new equipment and expertise, the company is well-positioned to meet the evolving needs of these growing markets.

The announcement of these new developments has been met with excitement from existing and potential clients, as well as industry experts. It further solidifies Rayming Pcb's position as a leader in the PCB manufacturing sector and reaffirms their commitment to innovation and excellence.

As the electronics industry continues to evolve and demand for high-quality PCBs grows, Rayming Pcb is poised to meet these challenges head-on. With their ongoing investments in technology, research, and sustainability, the company is well-equipped to continue providing top-notch solutions to their clients and lead the way in the ever-changing world of electronics manufacturing.

Company News & Blog

How to Make PCBs: A Beginner's Guide to Printed Circuit Board Design and Manufacturing

PCB Making Company Introduces Revolutionary Technology for Electronic Components ManufacturingIn the ever-evolving world of electronics manufacturing, PCB Making Company has introduced a groundbreaking technology that could revolutionize the industry. The company has formulated a unique method of producing printed circuit boards (PCBs), which is expected to significantly reduce the cost and time involved in PCB manufacturing.Based in the heart of Silicon Valley, the PCB Making Company has long been known for its exceptional work in the production of high-quality PCBs. The company has always focused on meeting the unique needs of its customers and providing the most reliable, efficient, and cost-effective solutions for electronic components manufacturing.The new technology, which was developed by PCB Making Company’s team of experienced engineers and technicians, is expected to take PCB manufacturing to the next level. The technology involves the use of a unique combination of materials that is said to offer improved thermal properties, exceptional electrical conductivity, and higher reliability.This innovative approach is expected to reduce the need for multiple layering and tedious processes involved in traditional PCB manufacturing. More importantly, this new technology will offer a significant reduction in the production cost, making it an ideal option for businesses seeking to cut down their manufacturing budget.According to John Doe, CEO of PCB Making Company, the new technology is a game-changer for the industry. “We are excited to introduce this breakthrough technology to the world. Our company has always been at the forefront of innovation, and this new technology is proof of our commitment to pushing the boundaries of what is possible in electronics manufacturing.”The new PCB technology is expected to have a significant impact on various industries, including aerospace, defense, and medical devices manufacturing. These industries require highly complex and reliable electronic components, and the new technology will help meet these requirements while reducing the production cost.Additionally, the new technology is expected to improve the overall energy efficiency of electronic devices. Today, energy efficiency is essential in various industries, and the new PCB technology is a significant step towards achieving this goal.PCB Making Company’s innovative approach to electronic components manufacturing is a testament to the company's commitment to providing the most advanced and effective solutions for its customers. With this new technology, PCB Making Company has set a new standard for the industry, and it is anticipated that other companies will follow suit.In conclusion, the development of the new PCB technology by PCB Making Company is a significant milestone in electronics manufacturing. The technology promises to offer a range of benefits, including reduced production cost, improved energy efficiency, and enhanced reliability. It is a testament to the company's commitment to innovation and providing the most advanced solutions for its customers.

Expert Tips for High Volume PCB Assembly

high volume PCB assembly is one of the most critical and complex operations in the electronics manufacturing industry. It involves the assembly of a large number of printed circuit boards (PCBs) with various electronic components such as resistors, capacitors, diodes, and integrated circuits. This process requires precision, efficiency, and advanced technologies to ensure the highest quality and reliability of the final product. One company that has excelled in high volume PCB assembly is {Company Name}.{Company Name} is a leading provider of electronic manufacturing services (EMS) with a strong focus on high volume PCB assembly. With state-of-the-art facilities and advanced equipment, the company has the capability to handle large-scale production of PCBs for a wide range of applications, including consumer electronics, automotive, industrial equipment, medical devices, and more.The high volume PCB assembly process at {Company Name} begins with the careful selection of high-quality materials and components to ensure the reliability and performance of the final product. The company works closely with its suppliers to source the best materials and components that meet the specific requirements of each customer's project.Once the materials and components are procured, the PCB assembly process begins with the placement of the components on the PCBs. {Company Name} utilizes advanced pick-and-place machines and automated assembly lines to achieve high precision and efficiency in the component placement process. These machines are capable of placing thousands of components per hour, ensuring fast and accurate assembly of the PCBs.After the components are placed, the PCBs undergo a series of soldering processes to securely attach the components to the board. {Company Name} utilizes advanced soldering technologies such as reflow soldering and wave soldering to achieve high-quality solder joints and ensure the reliability of the assembled PCBs.In addition to the assembly of the PCBs, {Company Name} also provides a range of testing and inspection services to ensure the quality and reliability of the final product. The company uses advanced testing equipment and inspection techniques to detect any defects or issues in the assembled PCBs, allowing for quick and efficient remediation.One of the key advantages of working with {Company Name} for high volume PCB assembly is its commitment to quality and customer satisfaction. The company has established rigorous quality control processes and standards to ensure that every PCB assembly meets the highest quality and reliability standards.Furthermore, {Company Name} is dedicated to providing a seamless and efficient manufacturing experience for its customers. The company offers comprehensive project management and logistics support to ensure that the high volume PCB assembly process is completed on time and within budget.Overall, {Company Name} has proven itself as a reliable and trusted partner for high volume PCB assembly. With its advanced technologies, commitment to quality, and customer-centric approach, the company has established itself as a leader in the electronics manufacturing industry.In conclusion, high volume PCB assembly is a critical operation in the electronics manufacturing industry, requiring precision, efficiency, and advanced technologies. {Company Name} has excelled in this area, offering high-quality PCB assembly services for a wide range of applications. With its commitment to quality, customer satisfaction, and advanced capabilities, the company has established itself as a trusted partner for high volume PCB assembly.

Complete Guide to Prototype PCB Assembly for Start-ups and Small Businesses

Prototype PCB Assembly is an essential part of the PCB manufacturing process. It is crucial for companies to ensure that their prototype PCB assembly is of the highest quality to guarantee the success of their products. With the increasing demand for electronic devices, the need for high-quality prototype PCB assembly has grown tremendously. As a result, companies are constantly on the lookout for reliable and efficient prototype PCB assembly services.In this regard, {Company Name} has emerged as a leading provider of prototype PCB assembly services. With years of experience in the industry, they have established themselves as a trusted partner for companies looking for top-notch prototype PCB assembly solutions. Their commitment to quality, efficiency, and reliability has made them a preferred choice for many companies across different industries.{Company Name} offers a wide range of prototype PCB assembly services, including PCB fabrication, component sourcing, PCB assembly, and testing. They have a team of experienced professionals who are dedicated to delivering the highest quality prototype PCB assembly services to their clients. Their state-of-the-art facilities and advanced equipment enable them to meet the diverse needs of their clients with utmost precision and efficiency.One of the key strengths of {Company Name} is their ability to tailor their prototype PCB assembly services to meet the specific requirements of their clients. Whether it is a small-scale project or a large-scale production run, they have the capabilities to handle it with utmost expertise and professionalism. This flexibility and adaptability have made them a sought-after partner for companies of all sizes.In addition to their technical capabilities, {Company Name} takes pride in their commitment to customer satisfaction. They understand the importance of open communication and collaboration with their clients to ensure that their prototype PCB assembly services are aligned with the clients' expectations and requirements. This customer-centric approach has earned them a reputation for reliability and trustworthiness in the industry.Furthermore, {Company Name} is committed to upholding the highest quality standards in their prototype PCB assembly processes. They adhere to strict quality control measures at every stage of the assembly process to ensure that the final product meets the highest standards of quality and performance. Their dedication to quality has set them apart as a leading provider of prototype PCB assembly services in the industry.As a forward-thinking company, {Company Name} is continuously investing in research and development to stay ahead of the curve in the rapidly evolving PCB manufacturing landscape. They are constantly exploring new technologies and methodologies to enhance their prototype PCB assembly services and offer innovative solutions to their clients. This proactive approach has enabled them to stay at the forefront of the industry and deliver cutting-edge prototype PCB assembly services to their clients.In conclusion, {Company Name} is a trusted provider of prototype PCB assembly services, known for their commitment to quality, efficiency, and customer satisfaction. With their unparalleled expertise, state-of-the-art facilities, and customer-centric approach, they have carved a niche for themselves in the industry as a reliable and efficient partner for companies seeking top-notch prototype PCB assembly solutions. As the demand for electronic devices continues to grow, {Company Name} is well-positioned to meet the evolving needs of the industry and continue to be a leading force in the prototype PCB assembly space.

Understanding the Basics of DFM (Design for Manufacturability) in PCB Manufacturing

DFM in PCB (Design for Manufacturing in Printed Circuit Board) is a crucial aspect of the PCB manufacturing process. It ensures that the design of the PCB is optimized for efficient and cost-effective manufacturing. By incorporating DFM principles into the design phase, manufacturers can avoid costly errors and delays during production.{Company Name} is a leading PCB manufacturing company that specializes in producing high-quality and reliable circuit boards for various industries. With state-of-the-art facilities and a team of experienced engineers, they are committed to delivering superior PCB solutions to their customers.Recently, {Company Name} has announced that they have enhanced their DFM capabilities to further improve the quality and efficiency of their PCB manufacturing process. By investing in advanced DFM software and training their engineers on the latest DFM guidelines, {Company Name} aims to streamline their production workflow and deliver even higher quality PCBs to their customers.DFM in PCB involves several key elements, including design optimization, material selection, and process validation. By utilizing DFM software, {Company Name} can analyze the design of the PCB and identify any potential manufacturability issues, such as component placement, trace width, or spacing constraints. This allows them to make necessary adjustments to the design early in the process, reducing the risk of manufacturing errors and ensuring that the final PCB meets performance requirements.In addition, {Company Name} is also focusing on material selection as part of their DFM strategy. By carefully choosing the right materials for each PCB design, they can ensure that the final product meets the necessary performance and reliability standards. This involves considering factors such as thermal properties, signal integrity, and cost-effectiveness to achieve the best possible outcome for their customers.Furthermore, process validation is a critical aspect of DFM in PCB. By simulating the manufacturing process and conducting thorough testing, {Company Name} can identify any potential issues before they arise during production. This proactive approach enables them to address any concerns and make necessary adjustments to the design before manufacturing, ultimately saving time and costs.With these enhancements to their DFM capabilities, {Company Name} is confident that they will be able to offer their customers even better service and products. By incorporating DFM principles into their PCB design process, they are positioning themselves as a reliable and efficient partner for their customers' PCB manufacturing needs."We are committed to providing our customers with the highest quality PCB solutions, and our enhanced DFM capabilities are a testament to that commitment," said [Spokesperson's Name], [Position]. "By investing in advanced DFM software and training our engineers on the latest DFM guidelines, we are confident that we can further improve the quality and efficiency of our PCB manufacturing process."{Company Name}'s dedication to DFM in PCB reflects their ongoing commitment to innovation and excellence in the industry. With their enhanced capabilities, they are well-positioned to meet the evolving needs of their customers and continue to be a leader in the PCB manufacturing sector.

Custom Medical PCB Assembly Services for Manufacturing Needs

Medical Pcb Assembly, in combination with the company introduction of a leading electronics manufacturing services (EMS) provider, has been making significant strides in the healthcare industry. The company, specializing in the design and assembly of printed circuit boards (PCBs), has been at the forefront of providing advanced electronic solutions for various medical devices and equipment.The demand for medical PCB assembly has been steadily increasing as the healthcare industry continues to rely on advanced technology for diagnosis, treatment, and patient care. The need for high-quality, reliable, and efficient PCBs in medical devices has become paramount, and [company name] has been instrumental in meeting these demands.With a dedicated team of experienced engineers and state-of-the-art manufacturing facilities, [company name] has been able to cater to the specific requirements of the medical industry. From precision PCB design to assembly and testing, the company has been able to deliver top-notch solutions for a wide range of medical applications.The medical PCB assembly services offered by [company name] are compliant with the stringent regulatory standards and certifications required for medical devices. This ensures that the PCBs meet the highest quality and safety standards, crucial for the reliability and performance of medical equipment.In addition to quality, [company name] also offers a range of value-added services such as design for manufacturability (DFM), design for test (DFT), and supply chain management. These services help streamline the entire PCB assembly process, resulting in cost-effective solutions and quicker time-to-market for medical device manufacturers.The company's expertise in medical PCB assembly extends to a wide array of medical devices, including patient monitoring systems, diagnostic equipment, imaging devices, surgical instruments, and more. These devices require highly reliable and durable PCBs to ensure precision and accuracy in their functions, and [company name] has been able to meet these requirements with its advanced assembly capabilities.One of the key factors that set [company name] apart in the medical PCB assembly space is its commitment to innovation and continuous improvement. The company invests heavily in research and development to stay ahead of the curve in terms of technology and manufacturing processes. This allows [company name] to offer cutting-edge solutions that are tailored to the evolving needs of the healthcare industry.Furthermore, [company name] is dedicated to sustainability and environmental responsibility in its manufacturing practices. The company adheres to strict environmental standards and regulations, ensuring that its processes have minimal impact on the environment. This commitment to sustainability has not only earned [company name] a positive reputation in the industry but also resonates well with medical device manufacturers who are increasingly conscious of the environmental footprint of their supply chain partners.In conclusion, [company name] has established itself as a leading provider of medical PCB assembly solutions, catering to the specific requirements of the healthcare industry. With a focus on quality, innovation, and sustainability, the company has been able to deliver reliable and advanced PCB assembly services for a diverse range of medical devices. As the demand for sophisticated medical equipment continues to grow, [company name] is well-positioned to be a trusted partner for medical device manufacturers seeking high-quality and efficient PCB solutions.

Top-Quality PCB Manufacturer Produces High-Quality PCBs for Various Industries

[Company Name] is a leading high quality PCB manufacturer that has been providing exceptional products and services to its customers for over 20 years. The company prides itself on its commitment to quality, innovation, and customer satisfaction.With a state-of-the-art manufacturing facility and a team of highly skilled professionals, [Company Name] is able to produce a wide range of PCBs to meet the diverse needs of its clients. From single layer to multi-layer, flexible to rigid, and quick turn prototypes to full production runs, the company has the capabilities to deliver high quality products on time and within budget.In addition to its manufacturing capabilities, [Company Name] also offers a range of value-added services such as PCB assembly, testing, and design support. This enables the company to provide a comprehensive solution to its customers, from concept to final product.The company's commitment to quality is evident in its stringent quality control processes and certifications. [Company Name] is ISO 9001 certified, ensuring that every product that leaves its facility meets the highest standards of quality and reliability. In addition, the company is committed to continuous improvement and invests in the latest technology and equipment to stay ahead of the curve in the ever-evolving PCB industry.One of the key differentiators of [Company Name] is its dedication to customer satisfaction. The company understands that every customer has unique needs and works closely with them to provide tailored solutions that meet their specific requirements. This customer-centric approach has earned [Company Name] a reputation for excellence in the industry and has resulted in long-standing relationships with many loyal clients.Furthermore, [Company Name] is committed to environmental sustainability and operates its facility in compliance with environmental regulations. The company strives to minimize its impact on the environment by implementing eco-friendly practices and responsibly managing its waste and energy usage.[Company Name] is also a socially responsible organization and is committed to giving back to the community. The company supports various charitable initiatives and actively engages in corporate social responsibility activities to make a positive impact on society.In conclusion, [Company Name] is a trusted and reliable high quality PCB manufacturer with a proven track record of delivering exceptional products and services to its customers. With its state-of-the-art facility, skilled professionals, commitment to quality, and dedication to customer satisfaction, the company is well-positioned to meet the evolving needs of the PCB industry and continue its success for years to come.

Ultimate Guide to Understanding Circuit Board PCBs and Their Applications

The global PCB (printed circuit board) market is growing at a rapid pace, with advancements in technology driving the demand for more advanced and efficient circuit boards. One company that is leading the way in this industry is {Company Name}.{Company Name} is a leading manufacturer of high-quality PCBs, serving a wide range of industries including telecommunications, automotive, medical, and consumer electronics. With state-of-the-art facilities and a team of experienced engineers, {Company Name} has built a reputation for delivering reliable and innovative PCB solutions to its customers.The key to {Company Name}'s success lies in its commitment to investing in the latest technology and equipment to meet the evolving needs of the market. The company has a strong focus on research and development, constantly exploring new materials and processes to enhance the performance and reliability of its PCBs.One of the main products offered by {Company Name} is its advanced multilayer PCBs, which are designed to meet the complex demands of modern electronic devices. These PCBs are manufactured using advanced techniques to achieve high density, high speed, and high reliability, making them ideal for a wide range of applications.In addition to multilayer PCBs, {Company Name} also offers a range of other products including flexible PCBs, rigid-flex PCBs, and metal core PCBs. These products are designed to provide flexible and cost-effective solutions for different electronic applications, catering to the diverse needs of its customers.{Company Name} takes pride in its commitment to quality and customer satisfaction. The company adheres to strict quality control processes throughout the manufacturing process, ensuring that each PCB meets the highest standards of performance and reliability. This dedication to quality has earned {Company Name} a loyal customer base, with many customers relying on the company for their PCB needs.As the demand for more advanced and reliable PCBs continues to grow, {Company Name} is well-positioned to capitalize on this trend. The company is constantly expanding its production capacity and investing in new technologies to meet the increasing demand from its customers. This commitment to innovation and growth has enabled {Company Name} to establish a strong presence in the global PCB market.Looking ahead, {Company Name} is focused on continued innovation and expansion, with plans to introduce new products and services to further meet the evolving needs of the market. The company aims to remain at the forefront of the PCB industry, offering cutting-edge solutions that exceed the expectations of its customers.In conclusion, {Company Name} is a leading manufacturer of high-quality PCBs, with a strong focus on innovation and customer satisfaction. With advanced technology, reliable products, and a commitment to quality, {Company Name} is well-positioned to continue its growth and success in the global PCB market.

3D Printed Circuit Board (PCB) Printer for Hobbyists: A Complete Guide

Introducing a Revolutionary Hobbyist PCB PrinterIn today’s fast-paced world of innovation and technology, enthusiasts and hobbyists are constantly seeking new and efficient ways to bring their ideas to life. Whether it’s creating a custom circuit board for a new electronic project or designing a prototype for a groundbreaking invention, having the right tools at their disposal is crucial for turning their dreams into reality. That’s where the Hobbyist PCB Printer comes in.Developed by the industry-leading company {}, the Hobbyist PCB Printer is a game-changing device that is designed to make the process of creating professional-grade printed circuit boards (PCBs) accessible to everyone. With its user-friendly interface and powerful features, this innovative printer is poised to revolutionize the way hobbyists and electronics enthusiasts approach PCB design and manufacturing.The Hobbyist PCB Printer is equipped with state-of-the-art technology that enables users to quickly and easily design and produce high-quality PCBs right from the comfort of their own homes or workshops. With its precise printing capabilities, advanced software integration, and seamless workflow, this printer empowers hobbyists to take their projects to the next level without the need for expensive outsourcing or time-consuming manual methods.One of the standout features of the Hobbyist PCB Printer is its intuitive software, which allows users to effortlessly create and customize their PCB designs with a comprehensive suite of tools and functions. From schematics and layout design to component placement and routing, the software provides a seamless platform for hobbyists to bring their ideas to life with precision and accuracy.Additionally, the Hobbyist PCB Printer offers versatile printing options that cater to a wide range of project requirements. Whether it’s a single-layer board for a simple circuit or a multi-layer design for a complex electronic device, this printer can handle the job with ease, giving hobbyists the flexibility they need to bring their vision to fruition.Furthermore, the Hobbyist PCB Printer is designed with convenience and practicality in mind. Its compact and robust construction makes it suitable for any workspace, and its low maintenance requirements ensure that users can focus on their projects without worrying about complicated upkeep or technical issues.By combining cutting-edge technology with user-friendly design, the Hobbyist PCB Printer is set to become a must-have tool for hobbyists, makers, and electronics enthusiasts who are passionate about bringing their ideas to life. With its ability to streamline the PCB design and manufacturing process, this printer is sure to inspire creativity and innovation in the DIY electronics community.As the company behind the Hobbyist PCB Printer, {} is dedicated to empowering individuals to explore their creativity and turn their ideas into reality. With a proven track record of delivering high-quality and reliable solutions for the electronics industry, {} is committed to providing innovative tools and resources that make it easier than ever for hobbyists and enthusiasts to pursue their passions.In conclusion, the Hobbyist PCB Printer is a groundbreaking device that is set to revolutionize the way hobbyists and electronics enthusiasts approach PCB design and manufacturing. With its advanced features, user-friendly interface, and commitment to empowering creativity, this printer is sure to inspire a new wave of innovation in the DIY electronics community. Thanks to the innovative vision and dedication of {}, hobbyists and enthusiasts can look forward to a future filled with endless possibilities for bringing their ideas to life.

How to Assemble PCBs: A Step-by-Step Guide for Beginners

Assemble PCB, a leading electronic manufacturing services company, has recently announced its expansion plans to increase its production capacity and meet the growing demands of its customers. The company, known for its high-quality PCB assembly and quick turnaround times, has seen a surge in orders due to the increasing demand for electronic products across various industries.Assemble PCB specializes in providing turnkey PCB assembly services, including PCB prototyping, component sourcing, and full production assembly. With state-of-the-art manufacturing facilities and a team of experienced engineers, the company is able to deliver high-quality PCBs for a wide range of applications, including consumer electronics, automotive, medical devices, and industrial equipment.The expansion plans include the addition of new production lines and equipment to increase the company's manufacturing capabilities. By investing in the latest technology and machinery, Assemble PCB aims to streamline its production processes and improve efficiency, ultimately allowing the company to handle larger orders and meet tight deadlines.In addition to expanding its production capacity, Assemble PCB is also focused on enhancing its quality control measures to ensure that all assembled PCBs meet the highest standards of reliability and performance. The company is committed to maintaining strict quality assurance protocols throughout the assembly process, from initial design and layout to final inspection and testing.Assemble PCB's commitment to quality and customer satisfaction has earned it a strong reputation in the electronic manufacturing industry. The company prides itself on being able to provide tailored solutions to meet the unique requirements of each customer, whether it's a small startup or a large multinational corporation. By offering personalized customer support and flexible manufacturing services, Assemble PCB has built long-lasting partnerships with many clients who continue to rely on its expertise for their PCB assembly needs.With the expansion of its production capacity, Assemble PCB is well-positioned to take on new opportunities and further solidify its position as a leading electronic manufacturing services provider. The company's dedication to innovation, quality, and customer satisfaction will continue to drive its success as it moves forward in the ever-evolving electronics industry.Assemble PCB's expansion plans come at a time when the demand for electronic products is rapidly growing. With the increasing popularity of IoT devices, smart appliances, and electric vehicles, there is a greater need for reliable and high-performance PCBs. Assemble PCB is ready to meet this demand head-on with its expanded production capabilities and unwavering commitment to excellence.As the company prepares for the next phase of its growth, it remains focused on upholding its core values of integrity, innovation, and collaboration. By continuing to invest in its people, technology, and processes, Assemble PCB is poised to meet the evolving needs of its customers and provide them with the best-in-class PCB assembly services they have come to expect.In conclusion, Assemble PCB's expansion plans represent an exciting new chapter in the company's journey to becoming a leading force in the electronic manufacturing services industry. With its expanded production capacity and unwavering commitment to excellence, the company is well-equipped to meet the growing demands of the market and continue delivering top-quality PCB assembly services to its valued customers.

Exploring the Advantages of Multi Layer Circuit Boards for Enhanced Performance

Multi-Layer Circuit Board Revolutionizes Electronics IndustryIn the fast-paced world of electronics, innovation is the key to success. Rapid advancements in technology have enabled the development of increasingly complex devices, pushing the boundaries of what is possible. One groundbreaking innovation that is set to revolutionize the industry is the Multi-Layer Circuit Board (MLCB), a state-of-the-art technology that promises to enhance performance, durability, and efficiency in electronic devices.Developed by an industry-leading technology company, the MLCB is a significant breakthrough in circuit board design. Traditional circuit boards consist of a single layer of conductive material, limiting the amount of circuitry that can be integrated onto the board. However, MLCBs feature multiple layers of conductive material stacked on top of each other, allowing for a vast increase in circuit density and functionality. This technological advancement opens up a world of possibilities for electronics manufacturers, enabling them to create smaller, more powerful, and more capable devices.One of the key advantages of MLCBs lies in their ability to efficiently manage heat dissipation. Electronics generate a substantial amount of heat during operation, which can lead to performance degradation and even the failure of critical components. MLCBs utilize advanced thermal management techniques, such as the integration of thermally conductive materials and heat sinks, to dissipate heat more effectively and ensure optimal performance even under high loads. This breakthrough greatly enhances the reliability and longevity of electronic devices, reducing the need for frequent maintenance and replacements.Moreover, the increased circuit density of MLCBs allows for greater integration of electronic components onto a single board. This not only reduces the overall size of electronic devices but also improves their overall functionality. For example, smartphones equipped with MLCBs can house more advanced features, such as larger memory capacity, sophisticated camera systems, and enhanced processing power. This technology revolutionizes the way electronic devices are designed, offering manufacturers the opportunity to pack more innovative features into smaller and more refined form factors.The applications of MLCBs span across a multitude of industries. In the automotive sector, MLCBs enable the development of advanced driver assistance systems, smart sensors, and autonomous driving technologies. These circuit boards also find extensive use in the aerospace industry, where lightweight and compact electronics are crucial for saving space and reducing fuel consumption. Additionally, MLCBs play a vital role in the medical field, facilitating the creation of sophisticated medical devices, diagnostic equipment, and wearable health trackers. The possibilities are endless.Furthermore, the adoption of MLCBs is expected to drive significant cost savings in the electronics manufacturing process. The increased functionality and compactness of these boards mean that fewer components are required, resulting in reduced material and assembly costs. Additionally, the enhanced durability of MLCBs reduces the likelihood of failures and the associated costs of repairs or replacements. These cost-effective advantages make MLCBs an attractive choice for manufacturers looking to streamline their production processes and offer more competitive products in the market.The company behind this groundbreaking innovation, {}, has been at the forefront of technological advancements for decades. Known for their expertise and commitment to excellence, they have consistently delivered cutting-edge solutions that have shaped the electronics industry. By introducing the Multi-Layer Circuit Board, the company once again proves its dedication to driving innovation and propelling the industry forward.In conclusion, the Multi-Layer Circuit Board is set to transform the electronics industry. With its increased circuit density, efficient heat dissipation, and cost-effective advantages, MLCBs offer unparalleled possibilities for manufacturers to create smaller, more powerful, and more capable electronic devices. This groundbreaking technology, developed by {}, promises to shape the future of electronics and pave the way for a new era of innovation.