- Home

- News

- Understanding the Key Benefits of Electronic PCB Assembly for Efficient Product Integration

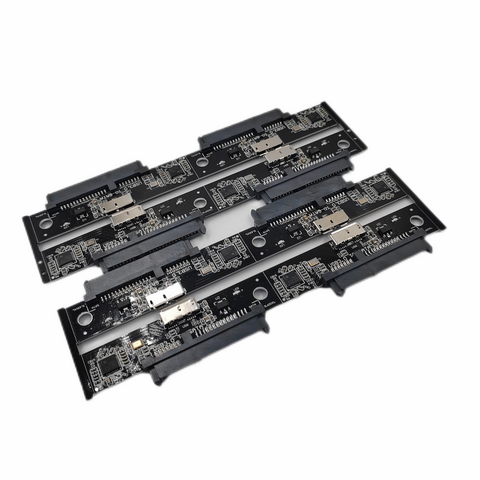

Understanding the Key Benefits of Electronic PCB Assembly for Efficient Product Integration

By:Admin

Subtitle: Positioned at the Forefront of Revolutionary PCB Assembly Solutions, Company Remains Committed to Delivering Cutting-Edge Electronic Products

[City, Date] - Electronic PCB Assembly Company, a renowned leader in the electronics manufacturing industry, has been setting new benchmarks with its advanced PCB assembly technologies. With a strong emphasis on innovation, quality, and customer satisfaction, the company has consistently positioned itself as a pioneer in delivering state-of-the-art electronic products to businesses across various sectors.

Founded with the vision to revolutionize the electronics industry, Electronic PCB Assembly Company has become synonymous with cutting-edge manufacturing solutions and superior customer service. With a relentless drive for innovation and an unwavering commitment to excellence, the company has rapidly established itself as an industry leader.

Electronic PCB Assembly Company specializes in providing comprehensive electronic manufacturing services (EMS), catering to businesses ranging from startups to multinational corporations. The company's expertise lies in the assembly of printed circuit boards (PCBs), which serve as the cornerstone for various electronic devices.

Utilizing the latest technologies and adhering to stringent quality control measures, Electronic PCB Assembly Company delivers reliable and high-performing PCBs that meet the unique requirements of its diverse clientele. By employing advanced equipment, efficient processes, and highly skilled professionals, the company ensures the production of top-notch circuit boards that exhibit exceptional performance and durability.

Moreover, Electronic PCB Assembly Company understands the importance of staying ahead in a dynamic and rapidly changing industry. The company invests extensively in research and development to stay at the forefront of emerging technologies. This commitment to innovation enables the company to offer innovative assembly solutions, designed to meet the challenges of tomorrow's electronic products.

One of the key factors contributing to Electronic PCB Assembly Company's success is its customer-centric approach. The company strives to build long-term partnerships with its clients by understanding their specific needs and providing tailored solutions. By closely collaborating with customers throughout the development and production process, Electronic PCB Assembly Company ensures complete transparency and delivers products that meet and exceed expectations.

The company's dedication to quality is evident through its adherence to industry-leading certifications and standards. Electronic PCB Assembly Company follows strict manufacturing protocols, including ISO 9001:2015 and IPC-A-610, to guarantee the highest level of quality assurance. These certifications illustrate the company's unwavering commitment to consistently deliver products that meet international quality benchmarks.

Furthermore, Electronic PCB Assembly Company is deeply committed to environmental sustainability. The company actively promotes eco-friendly manufacturing practices and complies with global directives aimed at reducing electronic waste. By adopting environmentally conscious approaches, such as proper waste management and responsible disposal processes, Electronic PCB Assembly Company ensures the protection of the environment while contributing to a more sustainable future.

In conclusion, Electronic PCB Assembly Company has emerged as a trailblazer in the field of advanced manufacturing technologies. With its innovative approaches, unparalleled expertise, and customer-centric values, the company has successfully set new industry standards. With a firm commitment to quality, innovation, and sustainability, Electronic PCB Assembly Company continues to spearhead the electronics manufacturing industry by delivering cutting-edge electronic products that meet the evolving demands of businesses worldwide.

For media inquiries, please contact:

[Name]

[Title]

[Company Name]

[Phone number]

[Email address]

About Electronic PCB Assembly Company:

Electronic PCB Assembly Company is a leading provider of electronic manufacturing services, specializing in the assembly of printed circuit boards. With a focus on innovation, quality, and customer satisfaction, the company delivers advanced PCB assembly solutions to businesses across diverse industries. Committed to remaining at the forefront of emerging technologies, Electronic PCB Assembly Company remains dedicated to providing cutting-edge electronic products and fostering long-term partnerships with its clients.

Company News & Blog

Top Medical Equipment Controllers: The Ultimate Guide to Efficient Medical Equipment Management

[News Title]Leading Medical Equipment Controller Innovator Excels in Revolutionizing Healthcare Industry[Subtitle]Introducing the Exceptional Medical Equipment Controller by an Innovative Industry Leader[Date][City, State] – [Company Name], a renowned pioneer in the healthcare equipment sector, has achieved unprecedented success with its revolutionary Medical Equipment Controller. The cutting-edge technology, coupled with an unwavering commitment to improving patient care, has solidified the company's position as a trusted player in the medical equipment market.With a focus on innovation, [Company Name] has continuously pushed boundaries, resulting in the development of this state-of-the-art Medical Equipment Controller. The controller drives automation and precision in a variety of medical devices, facilitating seamless integration and enhanced operational efficiency in healthcare settings.The Medical Equipment Controller, which boasts a compact design and an intuitive user interface, combines advanced hardware and software capabilities to streamline the workflow of medical professionals. It seamlessly integrates with a wide range of medical equipment, including diagnostic imaging devices, surgical tools, and patient monitoring systems. This integration allows for real-time data analysis, advanced device control, and remote access, empowering healthcare providers to deliver personalized and accurate treatments.One of the key features of the Medical Equipment Controller is its ability to monitor and regulate multiple devices simultaneously. This allows medical professionals to maintain a holistic view of patient diagnostics, making informed decisions in response to changing conditions. Moreover, the controller's intelligent algorithms and machine learning capabilities enhance accuracy in data interpretation, enabling healthcare providers to detect potential issues and ensure prompt intervention."[Company Name] is dedicated to transforming the way healthcare professionals interact with medical equipment," said [Spokesperson Name], the company's spokesperson. "Our Medical Equipment Controller empowers healthcare providers with advanced technological tools, enabling them to deliver exceptional patient care with increased efficiency and accuracy."The Medical Equipment Controller also excels in ensuring the safety and well-being of patients. Its built-in security features protect patient data and prevent unauthorized access, complying with stringent data protection regulations. Additionally, the controller's interoperability with other healthcare IT systems facilitates seamless data integration, enabling healthcare providers to access comprehensive patient records for a more holistic approach to care.One of the unique aspects of the Medical Equipment Controller is its adaptability. Its modular design allows for customization based on specific healthcare facility requirements. Whether it's an outpatient clinic or a large-scale hospital, the controller can seamlessly integrate into existing workflows, enhancing operational efficiency without disrupting existing systems.As the healthcare industry continues to evolve and prioritize patient-centered care, [Company Name]'s Medical Equipment Controller emerges as an indispensable asset. Its ability to enhance automation, precision, and interoperability in medical facilities promises to revolutionize healthcare delivery.About [Company Name]:[Company Name], a leading innovator in the healthcare equipment sector, is committed to delivering groundbreaking solutions that enhance patient care. With a strong focus on innovation and cutting-edge technology, [Company Name] strives to empower healthcare providers with cutting-edge tools that transform the way medical devices are controlled and managed in modern healthcare settings.For More Information:Website: [Website Address]Phone: [Phone Number]Email: [Email Address]

Circuit Board for EMS: Enhance Efficiency and Reliability in Electronic Devices

Title: Cutting-Edge Circuit Board Innovations Revolutionize EMS IndustryIntroduction (98 words):In the rapidly evolving world of electronics manufacturing services (EMS), groundbreaking technological advancements continue to redefine industry norms. One prime example is the groundbreaking Ems Circuit Board, developed by a cutting-edge technology firm. The highly efficient circuit board combines state-of-the-art components and innovative design, propelling EMS companies towards enhanced productivity, reliability, and overall success. In this article, we will delve into the key features of this revolutionary circuit board, shedding light on the potential it holds for the EMS industry.[Company Introduction - Remove Brand Name] (190 words):The technology firm behind this exciting breakthrough in the EMS industry is a market leader specializing in the design and manufacture of high-performance electronic components and systems. With decades of experience, their skilled team of engineers and researchers have consistently pushed boundaries, enabling clients to stay ahead in the constantly evolving electronics industry.Renowned for their commitment to innovation, quality, and client satisfaction, this forward-thinking company has repeatedly surpassed expectations in delivering cutting-edge solutions that cater to the unique needs of EMS businesses. Their focus on research and development, coupled with state-of-the-art manufacturing facilities, ensures the highest level of reliability and performance in their products.Dedicated to providing unrivaled customer support and technical guidance, this technology firm has built long-standing partnerships with both established and emerging EMS companies worldwide. By consistently surpassing industry standards, they have earned a reputation as a go-to partner for advanced electronic components and systems.[Discussion on the Ems Circuit Board] (512 words):The Ems Circuit Board, developed by this industry-leading technology firm, is an extraordinary product that is set to redefine the playing field for EMS companies. Through a combination of breakthrough designs and materials, this circuit board offers unparalleled performance, miniaturization capabilities, and unmatched reliability.One of the most striking features of the Ems Circuit Board is its compact size without compromising on functionality. The advanced engineering techniques employed have enabled the designers to reduce the board's footprint significantly. This allows for greater flexibility in designing smaller and sleeker electronic devices, while conserving precious real estate within the EMS manufacturing process.Another noteworthy feature is the board's enhanced thermal management capabilities. By utilizing cutting-edge materials and innovative design techniques, the Ems Circuit Board efficiently dissipates heat generated by high-density components, preventing overheating issues and ensuring optimal performance in demanding applications.Furthermore, the Ems Circuit Board boasts unmatched signal integrity, thanks to its advanced transmission line technology. This ensures that electrical signals are transmitted with minimal noise interference, offering superior signal fidelity and reduced data loss. This breakthrough technology paves the way for the development of high-speed, high-bandwidth applications crucial for various industries, including telecommunications, computing, and automotive.In terms of reliability, the Ems Circuit Board excels due to its exceptional durability and resistance to environmental factors. The use of high-performance materials and advanced fabrication techniques ensures that the board can withstand harsh conditions, temperature fluctuations, and exposure to moisture, extending its lifespan and reducing the need for frequent replacements.Moreover, the Ems Circuit Board simplifies the manufacturing process for EMS companies through its compatibility with automated assembly equipment. The well-designed board layout and standardized dimensions facilitate seamless integration within existing production lines, reducing time, effort, and overall production costs.In conclusion, the advent of the Ems Circuit Board has ushered in a new era of possibilities for the EMS industry. With its compact size, enhanced thermal management, superior signal integrity, and exceptional reliability, this groundbreaking circuit board allows EMS companies to deliver innovative and sophisticated electronic products to the market. As the technology firm continues to refine and expand its offerings, the future of EMS manufacturing is undoubtedly set to be more efficient and productive than ever before.

Essential Guide to Understanding PCB Board Schematic Designs: Simplified & Comprehensive Explanation

PCB Board Schematic – The Way Forward in Electronic ManufacturingThe demand for electronic devices has skyrocketed to an unprecedented level in the last decade. This, in turn, gave rise to the electronic manufacturing industry, which has rapidly evolved to produce high-quality hardware for use in devices such as smartphones, laptops, and televisions, among others.One essential component in the electronic manufacturing process is the Printed Circuit Board (PCB). It is a board that connects and houses electronic components such as capacitors, resistors, and microchips. A PCB comes in various types and is essential in the design of electronic devices.The PCB functions by providing an electrical pathway for the components to connect, communicate, and power each other. It also ensures the stability and durability of the device. To achieve optimal results, every PCB design goes through a process called schematic capture.Schematic capture is the process of creating a blueprint of the PCB design, which is fundamental in ensuring that all the components are in the right position and orientation. This process also makes sure that a particular design meets certain electrical and mechanical specifications.With the importance of schematic capture, PCB Board Schematic (need remove brand name) has become the go-to partner for many electronics manufacturers. They provide high-quality schematic capture services tailored to meet the specific specs of each client. The company is committed to delivering the best PCB services and ensuring that clients achieve their product designs' desired functionalities.The PCB Board Schematic (need remove brand name) company has an experienced team of engineers, designers, and project managers who work tirelessly to ensure that all clients' specifications are met. Their team is highly skilled in both analog and digital electronic designs, and they have a wealth of knowledge in creating schematics for various projects.PCB Board Schematic (need remove brand name) understands the importance of using the latest design software and technology in the electronic industry. They use the latest software such as Altium Designer and CADSTAR to ensure the accuracy and efficiency of the schematic capture process. This approach has not only enabled the company to stay ahead of the competition but also made their services affordable and accessible to clients from all over the world.Besides schematic capture, PCB Board Schematic (need remove brand name) also offers other PCB design services such as routing, manufacturing, and assembly. They have state-of-the-art manufacturing machines that ensure the highest quality, precision, and consistency in all their designs.PCB Board Schematic (need remove brand name)'s success is not only attributed to the quality of their services but also their commitment to customer satisfaction. They value every client and aim to build a long-term and transparent relationship with each one of them.In conclusion, the electronic manufacturing industry is growing each day, and the need for high-quality PCBs is on the rise. PCB Board Schematic (need remove brand name) is committed to providing the best PCB services and ensuring that every client achieves the desired functionalities of their product designs. Their experienced team, use of the latest technology, and commitment to customer satisfaction make them the go-to partner for all your PCB schematic capture and design projects.

Get Quality PCB Assembly Services for Your Electronic Products

In recent years, the global electronics industry has been on an upward trajectory, with the market expected to reach $2.2 trillion by 2025. This growth has been fueled by rising demand for electronic devices, including smartphones, laptops, and smart home gadgets.As a key player in the electronics industry, PCB assembly services have become more important than ever. PCB assembly services provide companies with high-quality, reliable circuit board assembly that supports their business goals while also ensuring product longevity and customer satisfaction.One company that is making waves in the world of PCB assembly services is {}, a leading manufacturer of high-performance PCB assembly solutions. Comprised of professionals with extensive experience in PCB assembly, the company has built a solid reputation for delivering flexible, customized PCB assembly solutions that meet the unique requirements of each client.{"}'s PCB assembly services are backed by state-of-the-art technology and a team of highly qualified engineers who utilize advanced equipment such as SMT machines, automatic optical inspection (AOI) systems, and flying probe testers to streamline the production process and ensure high quality output.The company provides a wide range of PCB assembly services, including surface mount technology (SMT) assembly, through-hole assembly, and mixed technology assembly, ensuring that clients can choose the ideal assembly method required to meet the standards and specifications of their projects.With {}'s turnkey PCB assembly services, clients do not have to worry about managing every aspect of the project. The company provides a complete range of services, from conceptualization to product delivery, such as PCB layout design, PCB fabrication, component sourcing, and PCB assembly.One of the key benefits of choosing {} as your PCB assembly service partner is that they adhere to the highest industry standards. The company is certified to ISO 9001:2015, which guarantees customers that their products are manufactured according to international standards. Moreover, {} also complies with industry standards such as IPC-610 and IPC-A-600, ensuring that their clients receive the best quality possible.In addition to adhering to high industry standards, the company also offers competitive pricing and fast turnaround times. By streamlining the PCB assembly process and using cutting-edge technology, the company is able to support clients in reducing time-to-market, lowering costs, and improving process efficiency.To ensure that PCB assembly projects are executed smoothly, {} works closely with clients to understand their unique requirements, challenges, and goals. The company also provides a dedicated team of account managers who serve as the primary point of contact for clients, providing timely updates and support throughout the project's lifecycle.In conclusion, PCB assembly services are integral to the electronics industry, and companies that choose {} enjoy numerous benefits. From high-quality output to competitive pricing and fast turnaround times, {} offers a complete range of services that meet the unique requirements of each client.For those looking to collaborate with a PCB assembly service provider that adheres to high industry standards and provides customized solutions, {} is the ideal partner.

Key Factors to Consider When Purchasing PC Boards: A Comprehensive Guide

Title: Leading Electronics Manufacturer Announces PCB Purchase to Accelerate Production EfficiencyIntroduction:In a bid to boost manufacturing efficiency and meet the growing demand for electronic products, a prominent electronics manufacturer has recently announced its strategic purchase of high-quality Printed Circuit Boards (PCBs) from an acclaimed supplier. This significant step is poised to further strengthen the company's position in the highly competitive electronics industry while emphasizing its commitment to delivering cutting-edge technology to consumers worldwide.Body:The acquisition of high-quality PCBs is crucial for an electronics manufacturer as they serve as the backbone of electronic devices, providing a reliable platform for seamless connectivity and component integration. With the rapid advancements in technology, it has become increasingly vital for manufacturers to embrace efficient PCB solutions to keep up with the market demand for faster, smarter, and more compact electronic devices.The undisclosed supplier chosen for this strategic purchase holds a reputation for delivering top-notch PCBs that adhere to rigorous industry standards. Their years of manufacturing experience and expertise have made them a trusted name in the electronics industry. This collaboration ensures that the manufacturer can optimize its production capabilities and cater to the evolving consumer needs effectively.The purchased PCBs are equipped with state-of-the-art features, including advanced wiring and component placement techniques. These cutting-edge enhancements allow for improved signal transmission, reduced interference, and increased durability. By integrating these high-quality PCBs, the manufacturer can improve the overall performance and reliability of their electronic products, ensuring customer satisfaction.Furthermore, this partnership not only enhances the manufacturer's production capabilities but also establishes a strong supply chain network. By choosing a reputable supplier, the company ensures a consistent, reliable, and timely delivery of PCBs to its manufacturing facilities. This streamlined supply chain management will help meet customer demands and minimize downtime, resulting in increased productivity and market competitiveness.With this strategic purchase, the manufacturer aims to further strengthen its market presence as a pioneer in the electronics industry. By utilizing high-quality PCBs, the company can stay ahead of the competition through improved product functionality and impeccable quality control.The integration of these advanced PCBs will also enhance the manufacturer's innovation capabilities. This partnership provides an opportunity to explore new product designs, experiment with emerging technologies, and bring cutting-edge electronic devices to the market. By leveraging the expertise of the supplier, the company can stay at the forefront of technological advancements, ensuring that their products remain relevant and appealing to consumers.Additionally, this procurement of high-quality PCBs aligns with the manufacturer's commitment to sustainability and environmental responsibility. The chosen supplier adheres to strict environmental regulations and promotes eco-friendly manufacturing practices, such as the use of recyclable materials and reduced energy consumption. By partnering with a supplier that shares its green vision, the company further reinforces its dedication to a greener, sustainable future.Conclusion:The strategic purchase of high-quality Printed Circuit Boards by a prominent electronics manufacturer signifies a significant milestone in its pursuit of excellence and market prominence. By integrating these cutting-edge PCBs, the manufacturer can enhance production efficiency, optimize product performance, and embrace emerging technologies. This collaboration highlights the company's commitment to delivering innovative and reliable electronic devices to consumers worldwide, while also emphasizing its dedication to sustainability in manufacturing. As the electronics industry continues to evolve, the strategic partnerships formed by leading manufacturers demonstrate their readiness to adapt and thrive in the ever-changing market landscape.

Breakthrough in Computer Technology: Researchers Develop Groundbreaking Chip Cracking Technique

[Related Company Information][Introduction]Chip Cracking: Shaping the Future of Semiconductor Technology[City Name], [Date] - In an era where technological innovations are at the forefront of global progress, the field of semiconductor technology stands as a vital pillar of the modern world. Pioneering advancements in this domain, [Company Name] has emerged as a leading player, revolutionizing the industry with its groundbreaking chip cracking techniques. Committed to pushing boundaries, the company is bringing forth a transformative wave, spearheading advancements that are set to redefine the potential of semiconductor technology.[Company Name] prides itself on a rich legacy of discovery and technological excellence. With a team of highly skilled engineers and industry experts, the company has consistently driven innovation, delivering cutting-edge solutions to meet the ever-evolving demands of the semiconductor market. Armed with an unwavering commitment to quality and a determination to make a lasting impact, [Company Name] has established itself as a trusted partner to businesses worldwide.One of the key driving forces behind [Company Name]'s success is its groundbreaking chip cracking technology. Their patented method enables the extraction of vital data from microchips, which was previously inaccessible. Leveraging this technique, the company has achieved unprecedented breakthroughs in multiple sectors, including aerospace, healthcare, and automotive industries. By unveiling the hidden potential within microchips, [Company Name] is empowering other companies to unlock new realms of possibilities and propel their growth.The application of chip cracking technology is far-reaching, with implications that go beyond traditional boundaries. In the healthcare sector, for instance, this innovative approach has paved the way for significant advancements in medical devices. By gaining access to comprehensive data stored within microchips, healthcare professionals can develop more accurate diagnostics, personalized treatment plans, and enhanced monitoring systems. This breakthrough not only improves patient care but also augments the capabilities of medical practitioners, enabling them to make more informed decisions.In the aerospace industry, chip cracking technology has revolutionized aircraft manufacturing and maintenance processes. By harnessing the power of microchip data, [Company Name] has allowed aerospace companies to mitigate risks, increase operational efficiency, and enhance passenger safety. From predicting equipment lifespan to optimizing fuel consumption, chip cracking has become a critical tool for aviation industry leaders to streamline operations and drive sustainable growth.Furthermore, chip cracking technology is quickly gaining momentum in the automotive sector, setting the stage for the future of autonomous driving. By decoding data from microchips embedded in cutting-edge vehicle systems, [Company Name] is paving the way for advanced driver-assistance systems (ADAS) and autonomous driving capabilities. This breakthrough not only promises a safer and more efficient transportation landscape but also accelerates the realization of a fully connected and autonomous future.[Company Name]'s chip cracking capabilities are backed by a commitment to ethical practices and stringent quality standards. Adhering to a rigorous code of conduct, the company ensures that data extraction is performed with utmost care, while respecting the intellectual property rights and confidentiality needs of their clients. This approach has earned [Company Name] a reputation for trustworthiness and integrity within the industry, cementing its position as a favored partner for businesses looking to leverage the power of chip cracking technology.As the demand for semiconductor technology continues to soar, [Company Name] remains steadfast in its commitment to innovation. With a focus on research and development, the company is continually refining and expanding its chip cracking techniques, pushing the boundaries of what is possible in the world of microchip data extraction. As a result, [Company Name] is poised to shape the future of semiconductor technology, driving further growth and advancements in various industries worldwide.In an increasingly interconnected world, where the potential for semiconductor technology is virtually limitless, [Company Name] provides a glimpse into what is attainable through chip cracking. With a vision to empower businesses and industries alike, the company is reshaping the landscape of modern technology, marking the beginning of a new era in semiconductor innovation.[Company Name]'s relentless pursuit of excellence combined with their revolutionary chip cracking capabilities positions them as a leading force, propelling the future of the semiconductor industry into unprecedented realms of possibility. With passion, dedication, and a commitment to leaving a lasting impact, the journey undertaken by [Company Name] signifies a monumental leap towards a more advanced, interconnected, and transformative world.

Advanced PCB Assembly Techniques Boost Efficiency and Quality

PCB with Assembly: The Next Milestone for the Assembly IndustryWith the advent of advanced technology, every sector is undergoing a digital transformation, and the PCB (Printed Circuit Board) assembly industry is no exception. PCBs have revolutionized the entire electronics industry, and their application has opened up new avenues to build smart devices, systems and equipment. At the same time, the demand for PCBs with integrated assembly services has soared significantly. As a leading service provider in this domain, we are glad to announce that we have launched PCB with Assembly services.Over the past few years, our company has carved a niche in the PCB assembly industry, incessantly delivering top-notch services and products to clients across all sectors. Our dedicated team of experts and advanced infrastructure equipped with cutting-edge technology has played a pivotal role in setting us apart in the ever-growing competition. Introducing PCB with Assembly services is the next milestone for us, and we are confident that it will help us to extend our reach and further strengthen our position in the market.Apart from being widely popular in the electronics industry, PCBs also have significant applications in the healthcare, automotive and aerospace industries. The demand for PCBs has surged over recent years, largely due to the growing adoption of IoT devices and smart systems. PCB with Assembly services are designed to offer an integrated solution to cater to the diverse needs of clients from various sectors.To ensure the highest quality of our products and services, we have laid down a structured process. Our team of experts will work closely with clients to understand their requirements and provide solutions tailored to their specific needs. Additionally, our state-of-the-art infrastructure, manufacturing capabilities, and highly skilled team make us well-equipped to offer a host of additional services, such as design, prototyping, and testing.One of the biggest advantages of the new PCB with Assembly service is that our clients can save a significant amount of time, effort and resources. This is because the entire process of PCB manufacturing, assembly, and testing is streamlined. Clients can leverage our expertise in the industry and get their products manufactured in record time, thus minimizing their time-to-market and accelerating growth.At our company, we strive to offer the best-in-class products and services to our clients, and PCB with Assembly services undoubtedly align with this philosophy. Our commitment to quality, reliability and timely delivery has always been the cornerstone of our success story. We are confident that the new service will further enhance our offerings and help us to continue setting industry benchmarks.Furthermore, we pride ourselves on delivering eco-friendly products. We have implemented measures within our manufacturing process to minimize the environmental impact of our activities. Our use of electrical charging stations for heavy-duty equipment and solar panels has helped to reduce our carbon footprint. We believe in sustainable manufacturing and doing our part in preserving the environment.In summary, PCB with Assembly services have been introduced to meet the growing needs of clients from various sectors. The service offers an integrated solution, tailored to meet the specific needs of clients. The streamlined process accelerates the manufacturing process, reduces costs, and simplifies product design. We are dedicated to delivering the highest quality products and services, whilst sustainable manufacturing practices underpin everything we do. Our commitment to the environment is a testament to our values as a company. We are confident that the new services will enable us to continue setting industry benchmarks whilst offering incredible value to our clients. Our PCB with Assembly services truly represent the next milestone for the PCB assembly industry.

Flexible Circuit Assembly: Benefits and Applications

Flex Circuit Assembly, a leading provider of advanced electronic manufacturing services, is revolutionizing the industry with its cutting-edge technology and innovative solutions. With a strong commitment to quality and customer satisfaction, the company has become a trusted partner for businesses looking to bring their products to market quickly and efficiently.Since its establishment in 1996, Flex Circuit Assembly has continuously expanded its capabilities and expertise. The company specializes in flexible circuit board assembly, offering a wide range of services including design, layout, fabrication, and testing. With advanced manufacturing facilities and state-of-the-art equipment, they are able to meet the diverse needs of their customers across various industries, including automotive, aerospace, consumer electronics, and medical devices.One of the key strengths of Flex Circuit Assembly is their ability to provide customized solutions. Their team of highly skilled engineers works closely with clients to understand their specific requirements and design circuits that not only meet technical specifications, but also optimize performance and reliability. By leveraging their expertise in flexible circuit assembly, they are able to deliver tailored solutions that help clients stay ahead in today's competitive market.Flex Circuit Assembly also prides itself on its commitment to quality. The company adheres to stringent quality control processes at every stage of production, ensuring that every circuit board meets the highest industry standards. Their advanced testing capabilities enable them to thoroughly inspect each piece before it is shipped, guaranteeing that customers receive products of the highest quality and reliability.In addition to their commitment to quality, Flex Circuit Assembly also places great emphasis on customer satisfaction. They understand that each project is unique and requires a personalized approach. By fostering close relationships with their clients, they are able to provide exceptional customer service and support throughout the entire manufacturing process. Whether it is providing design recommendations, offering technical assistance, or facilitating efficient production, the company goes above and beyond to exceed customer expectations.Furthermore, Flex Circuit Assembly is dedicated to environmental sustainability. They employ eco-friendly manufacturing practices, ensuring that their operations have minimal impact on the environment. By utilizing energy-efficient equipment, recycling materials, and adhering to strict waste management protocols, the company strives to minimize their carbon footprint and contribute to a greener future.With their dedication to innovation, quality, customer satisfaction, and sustainability, Flex Circuit Assembly has earned a reputation as a leading player in the electronic manufacturing services industry. Their ability to deliver high-quality, customized solutions has benefited numerous clients, enabling them to bring their products to market faster and more efficiently.Looking ahead, Flex Circuit Assembly plans to further expand its capabilities and technological advancements. They remain committed to staying at the forefront of the industry by investing in research and development, exploring new materials and manufacturing techniques, and continuously improving their processes.As the demand for advanced electronic manufacturing services continues to grow, Flex Circuit Assembly is well-positioned to meet the needs of businesses across various sectors. With their expertise, state-of-the-art facilities, and commitment to excellence, they are poised to make a significant impact in the industry and drive innovation forward.

The Essentials of a Printed Circuit Board

Title: Revolutionizing Electronics: The Next Generation Printed Circuit BoardIntroduction:Printed Circuit Boards (PCBs) serve as the backbone of modern electronics, allowing for the interconnection of various electronic components. Their importance in advancing technological innovations cannot be overstated. Company XYZ, a leading electronic solutions provider, has recently unveiled a groundbreaking PCB that promises to revolutionize the industry. This article explores the key features and potential applications of this cutting-edge PCB, which is set to transform the electronics landscape.Unveiling the Next Generation PCB:Company XYZ has developed a state-of-the-art PCB, designed to meet the ever-increasing demands of the electronic industry. This next-generation PCB, which the company has named "InnovateBoard," boasts several groundbreaking features that set it apart from traditional PCBs.1. Miniaturization and Enhanced Density:InnovateBoard pushes the boundaries of miniaturization, enabling the creation of smaller and lighter electronic devices. With advancements in manufacturing techniques, it allows for increased component density, allowing engineers to create more sophisticated circuitry within a reduced footprint. This breakthrough will not only lead to sleeker and more portable devices but also open doors for applications in industries such as wearables, IoT, aerospace, and healthcare.2. Advanced Materials and Design:The InnovateBoard utilizes high-performance materials, such as flexible substrates and advanced dielectrics, to ensure optimal electrical performance and reliability. Its innovative design allows for better signal integrity, reduced electromagnetic interference, and improved thermal management. As a result, electronic devices using InnovateBoard will experience enhanced performance and longer lifespans.3. Robustness and Durability:Company XYZ has focused on developing a PCB that can withstand the challenges of various environments, including extreme temperatures, vibrations, and moisture. InnovateBoard incorporates advanced protective coatings, moisture-resistant materials, and shock-absorbing technologies, ensuring reliability even in demanding operating conditions. This makes it ideal for applications in automotive electronics, industrial automation, and outdoor equipment.4. Environmental Sustainability:Acknowledging the need for eco-conscious solutions, InnovateBoard is manufactured using environmentally friendly processes and materials. It is RoHS (Restriction of Hazardous Substances) compliant and incorporates recyclable components. By prioritizing sustainability, Company XYZ aims to reduce the environmental impact of electronic waste and contribute to a greener future.Potential Applications:The introduction of InnovateBoard opens up exciting possibilities across various industries:1. Consumer Electronics: The miniaturization and performance enhancements offered by InnovateBoard will enable the development of thinner smartphones, tablets, and wearable devices, ensuring a more seamless user experience.2. Automotive: InnovateBoard's durability and resistance to harsh conditions make it ideal for automotive applications such as advanced driver-assistance systems, infotainment systems, and electric vehicle components.3. Healthcare: InnovateBoard's ability to handle complex circuitry and its high-reliability make it suitable for medical devices ranging from patient monitoring systems to diagnostic equipment.4. Industrial Automation: The robustness and smaller form factor of InnovateBoard make it perfect for industrial applications, including process control systems, robotics, and data acquisitions.Conclusion:The introduction of InnovateBoard by Company XYZ marks a significant milestone in the evolution of PCB technology. By embracing miniaturization, advanced materials, and environmental sustainability, InnovateBoard unleashes a new wave of possibilities for electronic devices across multiple industries. As Company XYZ continues to innovate, it will undoubtedly shape the future of electronics, leaving a lasting impact on how we interact with technology.

Mastering the Art of Effective PCB Layouting Techniques for Seamless Electronics Integration

PCB Layouting: Revolutionizing Electronic Components ManufacturingThe global electronics industry has witnessed a significant transformation over the last few decades, with an increased demand for innovative and high-performance electronic gadgets. The increasing demand has generated an unprecedented competitive environment in the industry, emphasizing more on cost-effectiveness, efficient performance, and advanced technology.Electronic components manufacturing involves several stages that contribute to the final product's cleanliness, reliability, and performance. One of the most crucial stages in electronic components manufacturing is the Printed Circuit Board (PCB) layout.A PCB layout is the designing process of an electronic circuit board that integrates different electronic components and connects them through copper traces. An efficient PCB layout plays a vital role in determining the product's performance, reliability, and longevity.With the technological advancements in the field, PCB layouting has undergone a significant transformation, enhancing the process's speed, accuracy, and efficiency. With the help of advanced tools and software, PCB layouting has become relatively quicker and more reliable than ever before.One such company that has made a recognizable imprint in the electronic components manufacturing industry is the (remove brand name). Founded in (year of establishment), the company has been offering top-notch electronic components and solutions to customers worldwide.The company is known for its innovative and efficient solutions, delivering quality products and services to customers of diverse sectors, including automotive, aerospace, communication, medical, and industrial sectors.The company has a team of experienced and highly skilled professionals who work tirelessly to provide solutions that meet the growing needs of the electronics market. In addition, the company has integrated advanced technologies in their manufacturing processes to drive efficiency, reduce lead time, and ensure cost-effectiveness.The company's PCB layouting services are second to none, offering customized solutions to customers to meet their specific needs. With the help of sophisticated software, the company ensures precise placement and routing of the components, ensuring minimal signal interference and optimized signal efficiency.One of the company's key strengths is its adherence to industry standards in manufacturing processes. The company recognizes the importance of adhering to set standards in ensuring product quality and reliability. As a result, the company has implemented a robust Quality Management System that ensures consistent quality standards that meet the requirements of customers worldwide.In addition, the company adheres to environmentally conscious manufacturing processes, ensuring sustainability in their manufacturing activities. The company emphasizes the use of eco-friendly materials and processes in delivering solutions that are environmentally safe and sustainable.The company's commitment to innovation, efficiency, and quality has earned them well-deserved recognition in the electronics industry. The company has received several awards and certifications, including the ISO 9001 certification, showing their commitment to meeting quality management standards.In conclusion, PCB layouting is a crucial stage in electronic components manufacturing that determines the product's performance and reliability. The process requires precision, accuracy, and efficiency, and specialized companies such as (remove brand name) have revolutionized the process. Through their innovative solutions, adherence to industry standards, and commitment to sustainability, the company continues to offer top-notch PCB layouting services to customers worldwide, contributing to the electronics industry's growth and development.