Shipping Information

| FOB Port | China (Mainland) |

| Lead Time | 7–15 days |

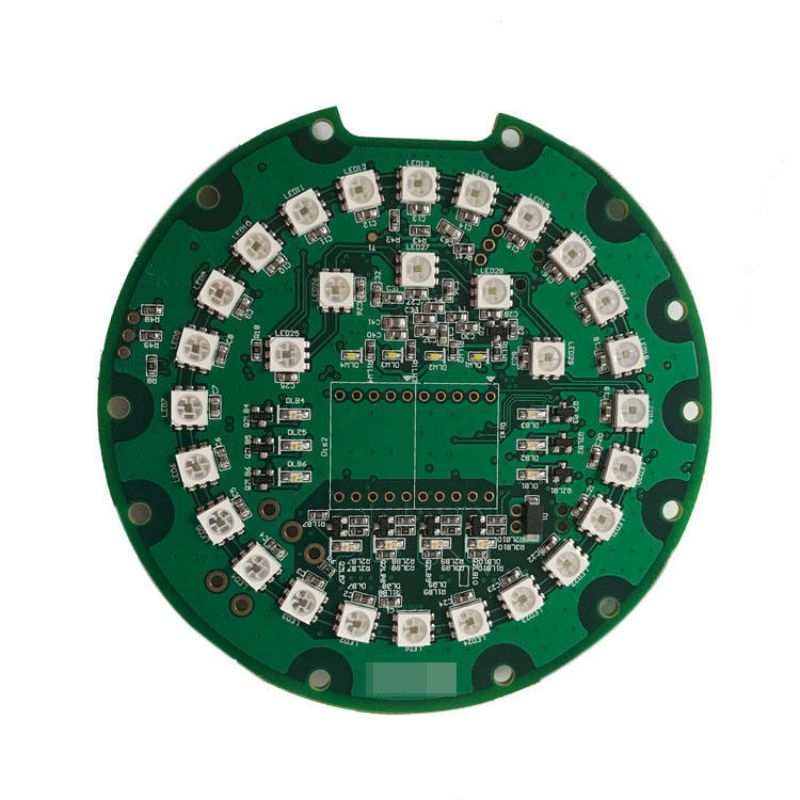

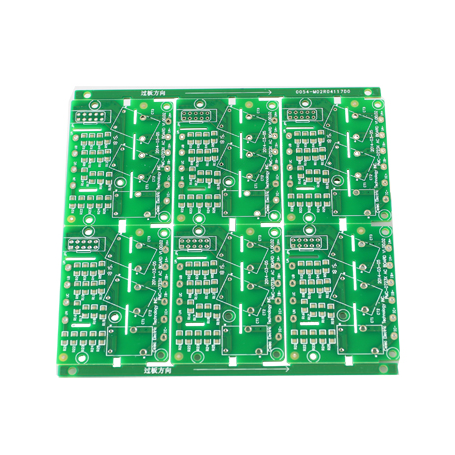

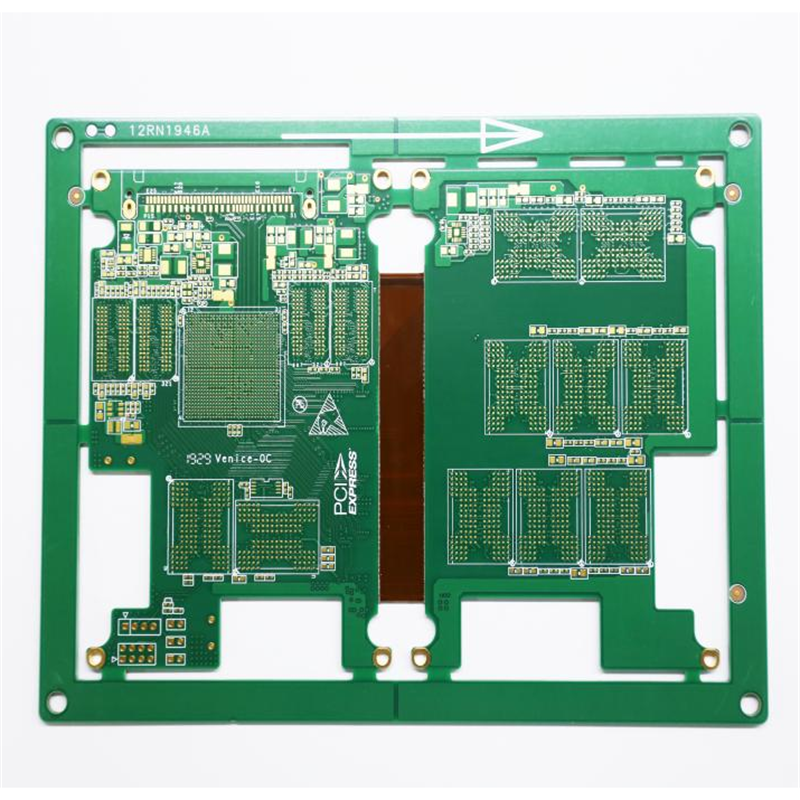

Our SMT capability:

- Electronic components material purchasing.

- Bare PCB fabrication.

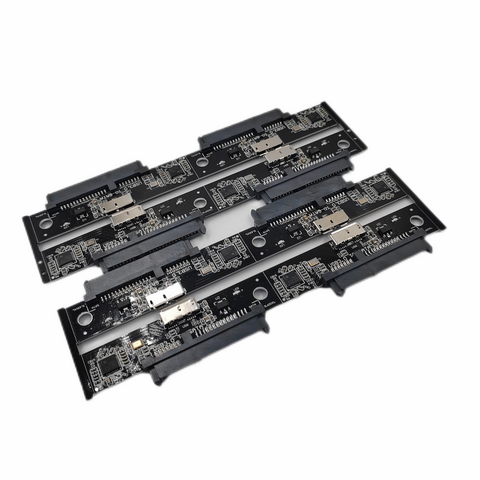

- PCB Assembly Service. (SMT, BGA, DIP).

- FULL Test: AOI, In-Circuit Test (ICT), Functioal Test (FCT).

- Cable, Wire-harness assembly,sheet metal,Electrical cabinet Assembly service.

- Conformal coating service.

- Prototyping and mass production...

Quality system:

- SMT assembly

- 2 sets high-speed SMT machine

- 2 sets automatic printers with fiduciary alignment

- 2 sets ICT test machines

- THT assembly

- 2 sets of wave soldering machine lines

- 1 set of automatic component inserter: IST-4000

Main Export Markets

- - Asia

- - Australasia

- - Central/South America

- - Eastern Europe

- - Mid East/Africa

- - North America

- - Western Europe

- ISO 9001:2008

- UL certification

- IPC-610D/E, class II compliance

- ICT, AOI, functional test

- Stock control under ERP system

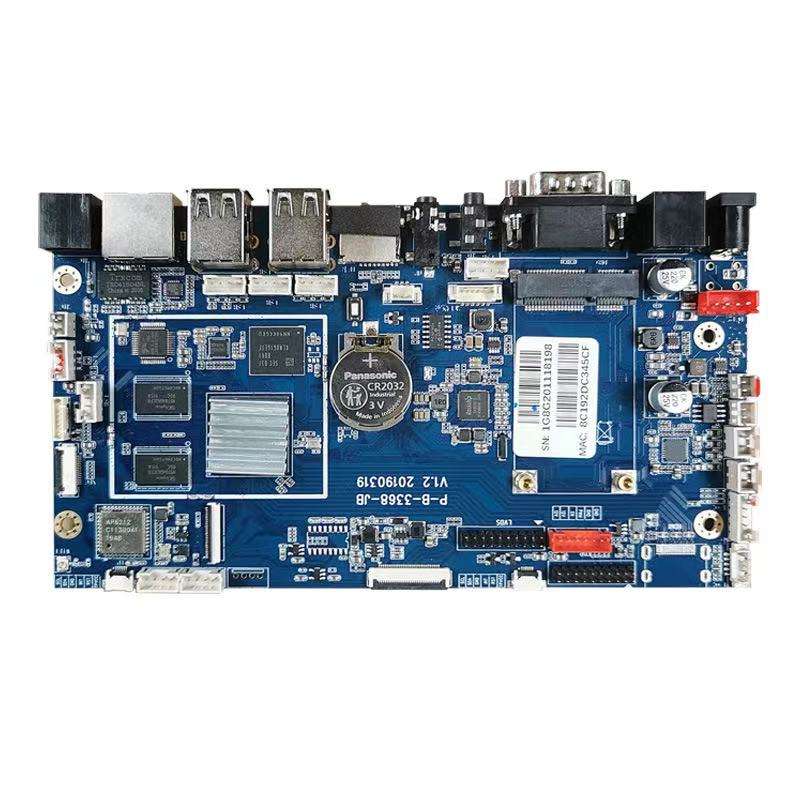

PCBA capabilities:

- 1) SMT assembly including BGA assembly

- 2) Accepted SMD chips: 01005, BGA, QFP, QFN, TSOP

- 3)Component height: 0.2-25mm

- 4)Min packing: 0201

- 5) Min distance among BGA: 0.25-2.0mm

- 6)Min BGA size: 0.1-0.63mm

- 7)Min QFP space: 0.35mm

- 8) Min assembly size: (X) 50 * (Y) 30mm

- 9)Max assembly size: (X): 350 * (Y) 550mm

- 10) Pick-placement precision: ±0.01mm

- 11) Placement capability: 0805, 0603, 0402, 0201

- 12) High-pin count press fit available

- 13)SMT capacity per day: 800,000 points

Advantages:

- 1) Strict product liability, taking IPC-A-160 standard

- 2)Engineering pretreatment before production

- 3) Production process control (5ms)

- 4) 100% E-test, 100% visual inspection, including IQC, IPQC, FQC, OQC

- 5) 100% AOI inspection, including X-ray, 3D microscope and ICT

- 6) High-voltage test, impedance control test

- 7)Microsection, soldering capacity, thermal stress test, shocking test

- 8)In-house PCB production

- 9) No minimum order quantity and free sample

- 10) Focus on low to medium volume production

- 11)Quick and on-time delivery